In the world of electronics design, engineers are often tempted by the flashiest new screens. High-resolution color panels are everywhere. However, when it comes to precision instruments, medical devices, and industrial meters, reliability is king. This is where the custom segment lcd display shines.

Many product designers assume that older technology is obsolete. That is a mistake. Segment liquid crystal displays (LCDs) remain the most efficient way to present data. They are robust, cost-effective, and incredibly energy-efficient.

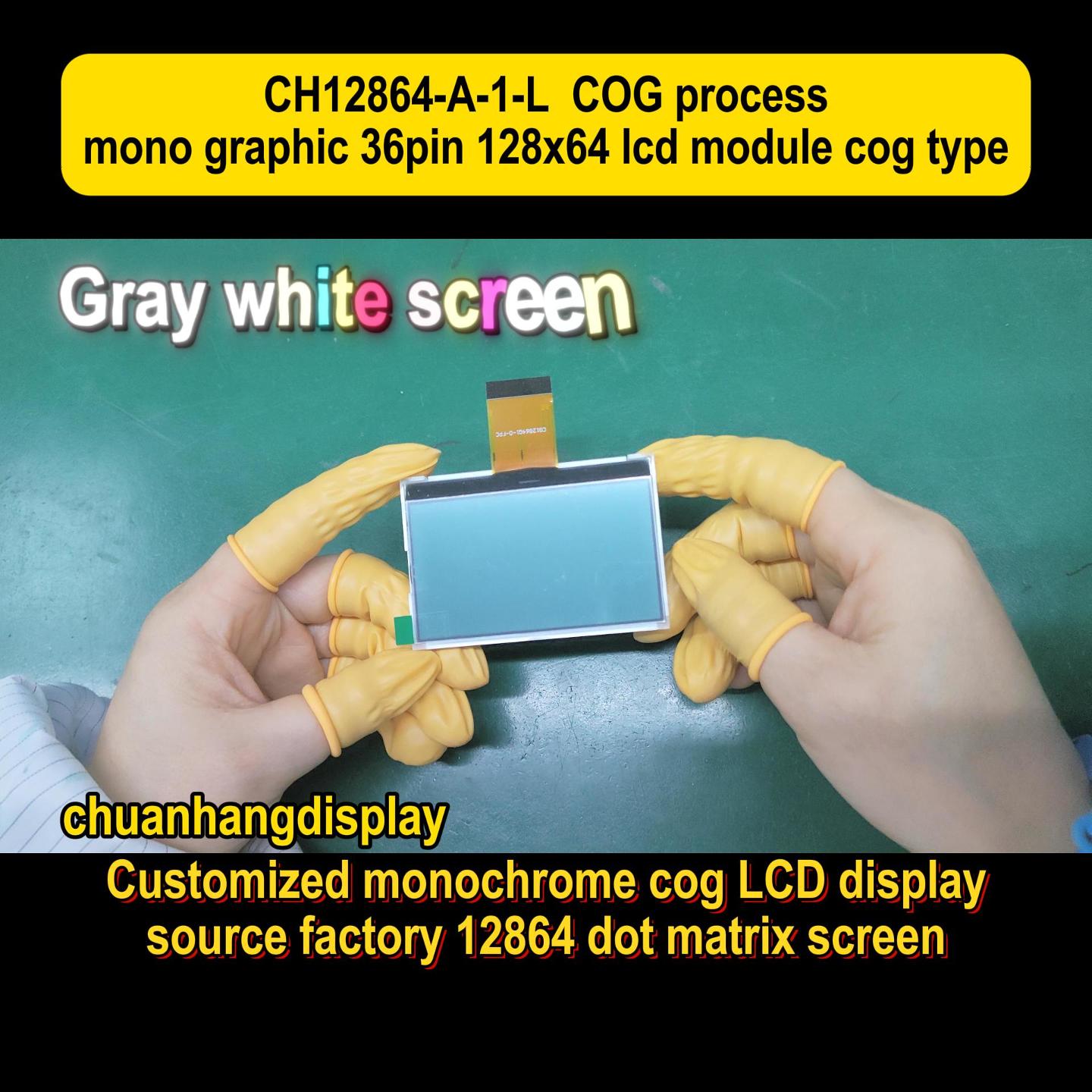

At Chuanhang Display, we see a growing demand for customized solutions. Off-the-shelf parts rarely fit the unique mechanical constraints of a new device. By customizing the glass, the pinout, and the icons, you create a product that looks professional and functions perfectly.

Before diving into design specifics, it is important to understand what we are building. A segment display uses liquid crystals sandwiched between two layers of glass. Unlike dot-matrix screens that use pixels to form images, segment displays use pre-defined shapes. These shapes are usually numbers (7-segment) or letters (14-segment), along with specific icons like battery indicators or warning signals.

Because the shapes are etched directly into the Indium Tin Oxide (ITO) layer, they are incredibly sharp. There is no pixelation. When you commission a custom segment lcd display, you decide exactly what shapes appear on the screen.

This simplicity translates to performance. The driver controller does not need to process complex graphics. It simply turns specific segments on or off. This reduces the processing load on your main CPU, which in turn simplifies your coding requirements.

The fluid inside the glass determines the viewing angle and contrast. In a custom project, you are not stuck with generic materials. You can choose the fluid type based on your operating environment.

For example, a device used in a server room has different needs than a dashboard inside a truck. We can adjust the fluid mixture to ensure the screen remains responsive even in freezing temperatures or extreme heat.

Why do engineers still choose this technology over OLED or TFT? The answer usually comes down to three factors: power, visibility, and longevity.

Battery life is a critical selling point for modern electronics. A standard TFT screen requires a backlight to be on constantly. It burns through power. In contrast, a segment LCD can operate in "reflective" mode. It uses ambient light to be visible.

Even with a backlight, the power consumption is a fraction of a color screen. For handheld medical devices or remote sensors, a custom segment lcd display is often the only viable option to achieve a battery life measured in months or years.

Have you ever tried to read a smartphone screen in direct sunlight? It washes out.

Segment displays excel outdoors. By using a reflective or transflective polarizer, the sun actually helps make the segments clearer. For outdoor meters, e-bike dashboards, and marine equipment, this readability is non-negotiable.

While there is an initial setup fee for custom tooling, the unit price of segment displays is very low. For high-volume production, this difference adds up. If you are manufacturing 10,000 or 50,000 units, the savings compared to a color screen are massive. Chuanhang Display helps clients optimize these designs to get the best price-to-performance ratio.

When you begin a custom project, the first major decision is the type of technology. There are several "modes" of LCD, each with different characteristics.

This is the most common and cost-effective type. It creates black segments on a gray or silver background. It is perfect for utility meters and simple readouts. The viewing angle is somewhat limited, but for devices looked at straight-on, it is excellent.

If you need a wider viewing angle, STN is the upgrade. It provides better contrast and allows the screen to be read from the side. The background color typically has a greenish or bluish tint, which can be neutralized with the right polarizer.

For a sharper, more professional look, FSTN (Film Compensated STN) turns the background white and the characters black. It looks very clean. DFSTN (Double FSTN) takes this further, offering a very dark background with light characters, creating a high-contrast "negative" image that looks very modern.

This is the premium option for segment displays. VA technology creates a pitch-black background with incredibly bright, colorful segments. It mimics the look of an LED or OLED screen but retains the simplicity of an LCD. It is highly popular in automotive and high-end audio equipment.

A custom segment lcd display is not just about the glass. How it connects to your circuit board (PCB) is equally important.

Metal pins are the most sturdy connection method. They are soldered directly into the PCB. This is ideal for environments with vibration, such as industrial machinery.

Zebra strips (elastomeric connectors) are rubber strips that conduct electricity. They are held in place by compression. This is great for small devices where you want to save space, but it requires a bezel to hold the LCD tightly against the board.

For the most compact designs, an FPC tail is used. This flexible ribbon cable can plug into a connector or be soldered. It allows the display to be placed away from the main PCB, giving your mechanical engineers more freedom.

Since LCDs do not produce their own light, you often need a backlight for night viewing. In a custom design, you can choose the exact color of the LED. White and blue are standard, but Chuanhang Display can implement RGB backlights or specific wavelengths for specialized equipment.

We can also design the backlight housing to prevent "light leakage," ensuring the light only comes through the segments where it is supposed to.

Many clients are intimidated by the word "custom." They fear it will take too long or cost too much. In reality, the process is streamlined.

We start by looking at your mechanical drawing. How much space do you have? What needs to be displayed? Do you need a battery icon, a WiFi symbol, or huge digits?

Our engineers create a technical drawing of the proposed LCD. This shows the physical dimensions, the active viewing area, and the pinout. You review this to ensure it fits your PCB.

Once the drawing is approved, we create the masks and tooling. This usually takes a few weeks. We then produce a small batch of samples for you to test.

After you approve the samples, we move to volume manufacturing. The consistency of a custom segment lcd display is very high because the segments are physically etched. Unlike software that can glitch, the segments are hard-wired into the glass structure.

The versatility of these displays keeps them relevant across many sectors.

Digital thermometers, blood pressure monitors, and glucose meters all use segment LCDs. They need to be hygienic, easy to wipe down, and extremely reliable. A fancy color touchscreen is often a liability in these settings because it consumes too much power and is fragile.

Factory floors are harsh. Dust, vibration, and electrical noise are common. Segment displays are immune to much of this interference. They provide operators with critical data—voltage, pressure, temperature—without distraction.

Electric scooters and bikes need dashboards that work in rain and sun. A custom segment solution allows the manufacturer to brand the dashboard with specific logos and layouts that match the vehicle’s aesthetic.

Look at your microwave, washing machine, or thermostat. They likely use a segment display. It is the most cost-effective way to provide a clear user interface. Chuanhang Display supplies many such components to appliance manufacturers who need durability.

There is a myth that custom LCDs have high NRE (Non-Recurring Engineering) charges. Years ago, this was true. Today, the tooling cost for a custom LCD is often less than the price of a single high-end laptop.

When you amortize that cost over a production run of a few thousand units, it becomes negligible. In exchange, you get a component that fits your product perfectly, rather than forcing your product to fit a standard screen.

Another misconception is that segment displays look "old." With technologies like VA (Vertical Alignment) and creative silkscreen printing, these displays can look sleek and futuristic. The design is entirely up to you.

The display is the face of your product. It is the primary way users interact with your technology. While it is tempting to chase the latest high-tech trends, the custom segment lcd display remains the champion of reliability, efficiency, and clarity.

By choosing a custom solution, you gain control over every aspect of the visual experience. You ensure the screen is readable in the specific environment it was designed for. You optimize battery life, extending the usability of your device.

At Chuanhang Display, we are dedicated to helping you navigate these choices. We bridge the gap between complex display physics and your product goals. Whether you are building a medical instrument or a smart meter, a custom display is often the smartest engineering decision you can make.

Q1: What is the typical lead time for developing a custom segment lcd display?

A1: Generally, the process takes about 3 to 5 weeks depending on complexity. It typically takes 2 to 3 days to generate a counter drawing after receiving requirements. Once the drawing is approved, tooling and sample production usually take about 2 to 3 weeks. Mass production lead times are typically 4 to 6 weeks after sample approval.

Q2: What is the minimum operating temperature for these displays?

A2: Standard LCD fluids usually operate between 0°C and +50°C. However, for industrial or outdoor applications, we can use "wide temperature" fluids. These allow the display to function correctly in ranges from -20°C to +70°C, and specialized automotive grade fluids can go even lower, down to -40°C.

Q3: Can I add color to a segment LCD without using a color filter?

A3: Yes, there are two common ways to do this. First, we can use "silk-screening" on the polarizer to add static colors to specific areas or icons (like a red warning zone). Second, we can use a multi-colored LED backlight to change the color of the entire display or specific sections, though silk-screening is the most common method for permanent multi-color effects on segment displays.

Q4: What is the difference between Reflective, Transmissive, and Transflective polarizers?

A4: A Reflective polarizer uses ambient light and has a mirror-like backing; it requires no backlight and is great for bright rooms. A Transmissive polarizer requires a backlight to be visible and looks great in low light but washes out in the sun. A Transflective polarizer is a hybrid; it reflects sunlight so it’s readable outdoors, but also allows a backlight to pass through for night viewing.

Q5: Is the tooling cost (NRE) for a custom display expensive?

A5: Compared to other electronic customizations, it is quite affordable. Tooling for a custom segment LCD usually ranges from a few hundred to just over a thousand dollars, depending on the size and pin type. This is a one-time fee. Once paid, you own the tooling, and future orders only consist of the unit price.