When designing a device that requires a visual interface, selecting the right display technology is a critical decision. The choice often narrows down to two prevalent options: OLED and LCD modules. Each technology offers distinct advantages and trade-offs in terms of picture quality, power consumption, durability, and cost.

Understanding the fundamental differences between an OLED LCD module and a traditional LCD module is essential for engineers, product designers, and procurement specialists. This comparison will help you identify the best fit for your specific application, whether it's a consumer gadget, industrial tool, medical device, or automotive display.

First, let's define the standard LCD module. LCD stands for Liquid Crystal Display. The module itself is a self-contained unit consisting of the LCD panel, a backlight (typically LED-based), driving electronics, and often a touch panel.

In an LCD, liquid crystals do not emit light themselves. They act as shutters, blocking or allowing light from the bright backlight to pass through color filters. This means black is achieved by trying to block this backlight, which is rarely 100% effective, leading to less deep blacks.

LCD modules are renowned for their high brightness, excellent sunlight readability, and long operational lifespan. They are a mature, cost-effective technology used in countless applications worldwide, from instrument panels to basic consumer electronics.

OLED stands for Organic Light-Emitting Diode. An OLED LCD module—more accurately termed an OLED display module—functions on a completely different principle. Each pixel is composed of tiny organic compounds that emit light when an electric current is applied.

This self-emissive characteristic eliminates the need for a separate backlight. When a pixel needs to be black, it simply turns off, producing true, perfect blacks and an essentially infinite contrast ratio. This results in stunning image quality with vibrant colors and remarkable clarity.

Let's break down the comparison into crucial performance and application categories.

Image Quality and Viewing Experience

OLED modules are the undisputed leaders in contrast and black level. The ability to turn off individual pixels creates a dynamic, punchy image. They also offer wider viewing angles with minimal color shift compared to many LCDs.

LCD modules, especially those with In-Plane Switching (IPS) technology, have made great strides in viewing angles. However, they cannot match the native contrast of OLED. Where high-brightness LCDs excel is in very bright ambient environments, where their powerful backlight can overcome glare.

Power Consumption and Efficiency

Power efficiency is highly application-dependent. An OLED module consumes power per pixel. Therefore, displaying a dark or mostly black image uses significantly less power than a bright white screen.

An LCD module's backlight is always on at a constant intensity, consuming a more consistent amount of power regardless of the displayed content. For interfaces with static, bright graphics, LCD can sometimes be more efficient. For dynamic content with dark themes, OLED often wins.

Lifespan and Burn-in Considerations

LCD modules have a long, proven track record of reliability, with lifespans often rated at 50,000 hours or more. The backlight may gradually dim, but image retention is not a typical issue.

OLED materials can degrade over time, with blue pixels aging faster than red and green. This can lead to "burn-in" or image persistence if a static image is displayed for extremely prolonged periods. Modern OLEDs and driving algorithms have mitigated this, but it remains a consideration for applications with fixed, high-contrast UI elements.

Form Factor and Design Flexibility

The lack of a backlight allows OLED modules to be incredibly thin and lightweight. They can also be made on flexible plastic substrates, enabling curved or even rollable displays—a significant advantage for innovative product design.

LCD modules are generally thicker due to the backlight and glass layers. While flexible LCDs exist, they are less common. LCD technology remains the standard for larger format displays and where rigid robustness is required.

Cost Analysis

LCD is a more mature and mass-produced technology, making it generally more cost-effective, especially for larger screen sizes and higher volumes.

OLED manufacturing is more complex, leading to a higher price point. The cost gap has narrowed for smaller sizes but remains a key factor in budget-sensitive projects.

Your application's specific needs should guide your choice between an OLED and an LCD module.

Choose an OLED module if: Your priority is superior image quality with deep blacks and high contrast (e.g., premium wearables, medical diagnostic imaging, high-end automotive clusters). You need a very thin or flexible form factor. Your interface uses a dark mode, optimizing power savings.

Choose an LCD module if: You require high brightness for outdoor or sunny environments (e.g., industrial handhelds, marine equipment, outdoor kiosks). Your project has strict cost targets. The display will show static content for extended periods. You need a very long, predictable lifespan with minimal risk of image retention.

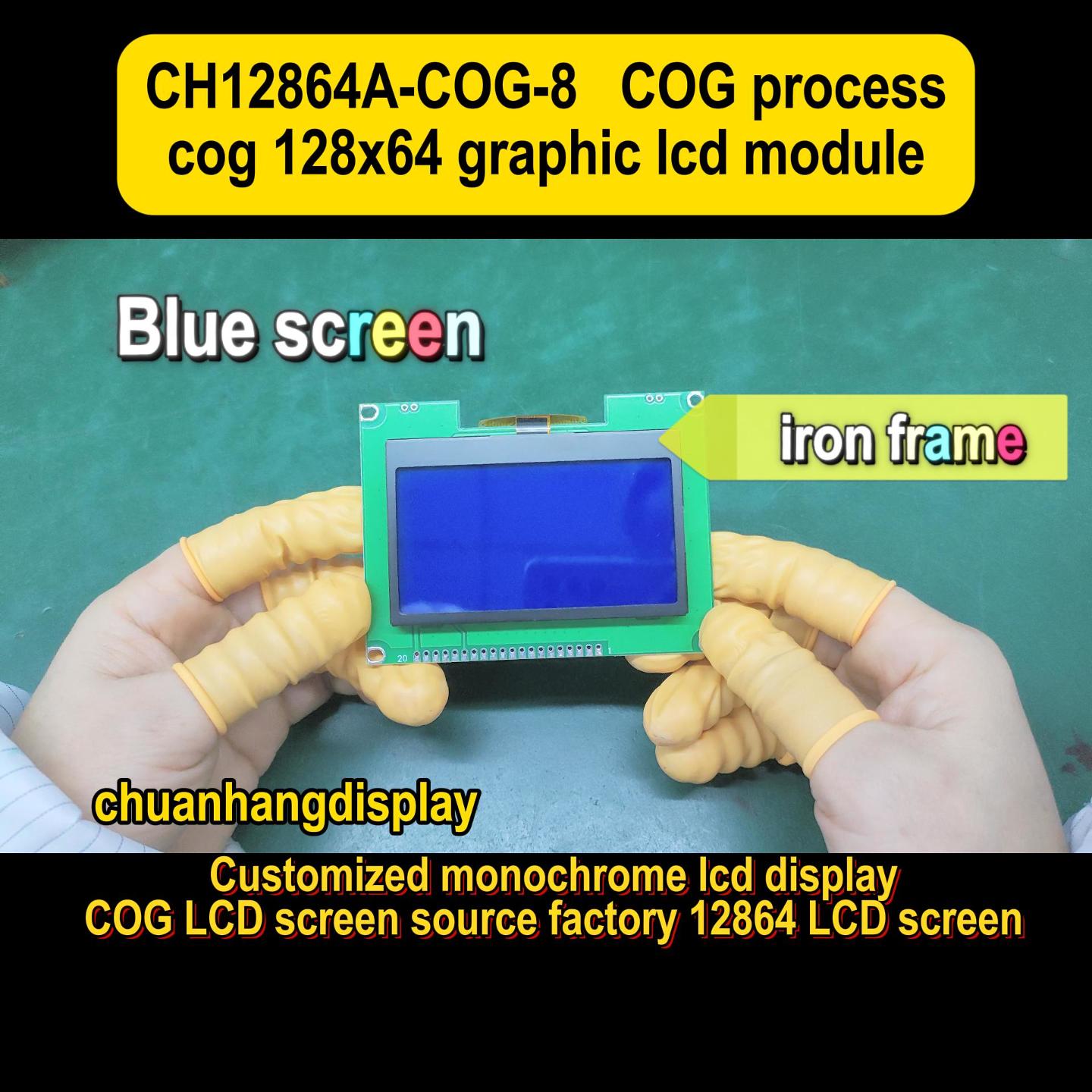

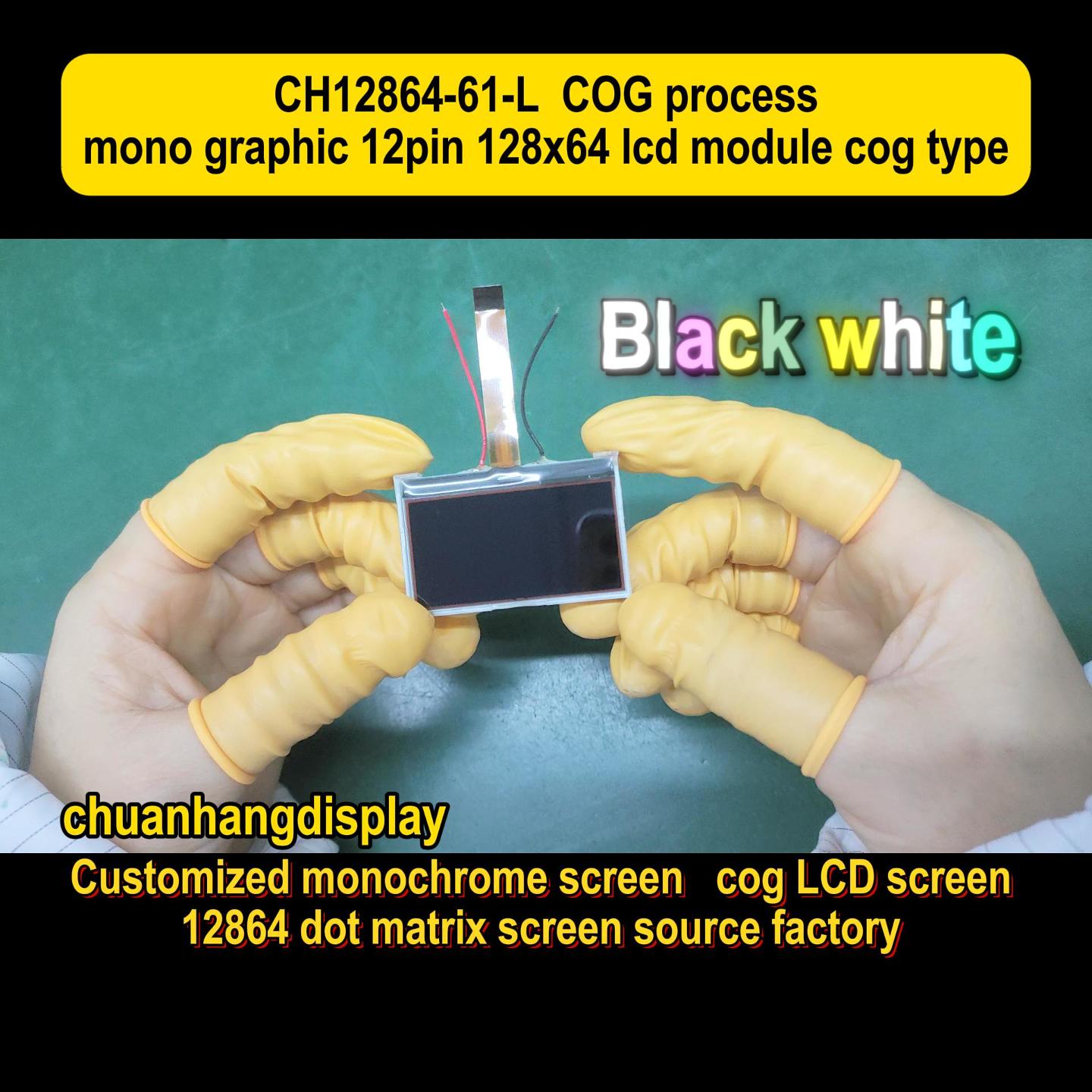

As a supplier of both advanced technologies, Chuanhang Display works with clients to navigate these decisions. We provide tailored OLED LCD module solutions, ensuring the selected display aligns perfectly with the technical requirements, environmental conditions, and budget of your product.

There is no universal "best" technology—only the best technology for your specific project. The OLED LCD module debate centers on trade-offs. OLED offers breathtaking image quality and design flexibility, while LCD delivers proven reliability, high brightness, and cost efficiency.

By carefully evaluating the factors of image quality, power use, durability, form factor, and cost against your product's requirements, you can make an informed decision. Partnering with an experienced manufacturer like Chuanhang Display can provide access to the latest innovations in both OLED and LCD modules, ensuring your final product stands out in a competitive market.

Q1: Can an OLED module be used in direct sunlight?

A1: While modern OLEDs have improved in brightness, traditional high-brightness LCD modules with strong backlights and anti-reflective coatings typically perform better in direct sunlight. Some new OLED technologies are addressing this, but for the brightest ambient conditions, LCD is often the safer choice.

Q2: Is burn-in still a major problem for OLED modules in industrial uses?

A2: It is a consideration, not necessarily a major problem. For industrial applications with static graphics, mitigation strategies are crucial. Chuanhang Display can implement features like pixel shifting, logo dimming, and recommend optimal operating conditions to minimize the risk significantly.

Q3: Which technology has a faster response time, OLED or LCD?

A3: OLED modules have a much faster pixel response time (microseconds) compared to standard LCDs (milliseconds). This makes OLED superior for applications requiring ultra-smooth motion, like virtual reality or fast-moving graphics, with virtually no motion blur.

Q4: Are OLED modules more fragile than LCD modules?

A4: Traditional glass-based OLED modules have similar fragility to glass LCDs. However, the organic materials in OLED can be sensitive to prolonged exposure to moisture and oxygen, which is why they are well-encapsulated. Flexible OLEDs on plastic substrates can be more robust against bending but have different handling requirements.

Q5: For a battery-powered IoT device, should I choose OLED to save power?

A5: It depends entirely on the user interface. If your UI is predominantly dark or black, an OLED module will likely be more power-efficient as it lights only necessary pixels. If your UI is mostly white or bright, the constant backlight of an LCD might consume less power. A power profile analysis of your specific screen content is recommended.