Sourcing components for electronic devices is never a simple task. For product managers and procurement officers, the screen is often the most critical component. It is the face of the product and the primary interface for the user. Consequently, finding the right lcd display factory is not just about comparing price sheets; it is about securing a partner that understands the intricate balance between quality, supply chain stability, and technical customization.

At Chuanhang Display, we have seen firsthand how the wrong choice in manufacturing partners can delay product launches or result in high return rates. Conversely, a strong partnership leads to market success. This article breaks down exactly what you need to look for when evaluating a manufacturer, ensuring your project moves from prototype to mass production without issues.

The first thing to assess is the physical reality of the production floor. A brochure might look nice, but the infrastructure dictates the quality. High-quality liquid crystal displays require pristine manufacturing environments.

You should verify if the manufacturer operates Class 1,000 or Class 100 clean rooms. Dust is the enemy of display bonding. Even microscopic particles can cause dead pixels or bonding failures.

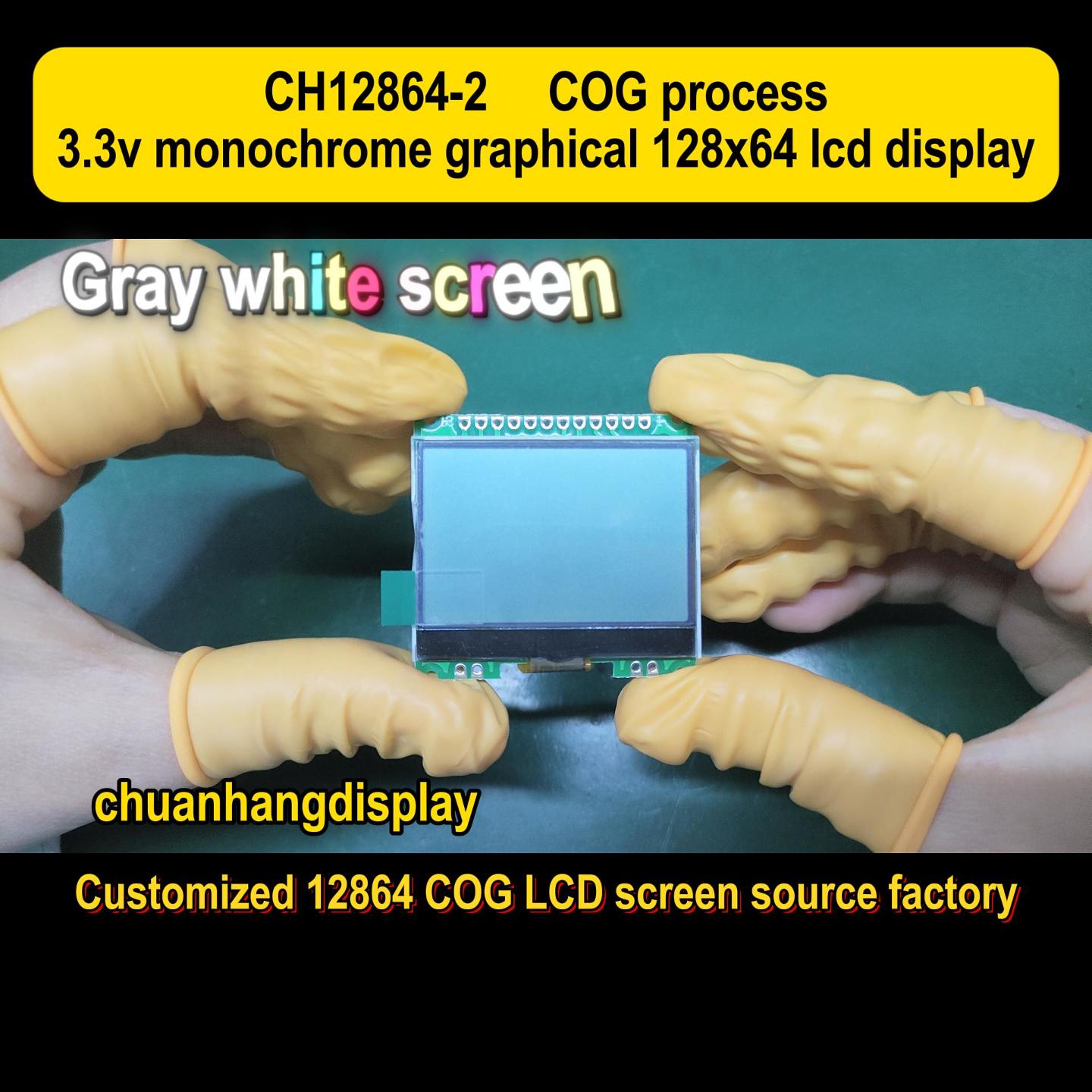

Furthermore, look for automation levels. Modern manufacturing relies heavily on automated lines for COG (Chip on Glass) and FOG (FPC on Glass) bonding. Automated Optical Inspection (AOI) equipment is also standard in top-tier facilities. This machinery detects defects that the human eye might miss, ensuring consistency across thousands of units. A factory relying too heavily on manual assembly for these critical steps often suffers from lower yield rates.

Off-the-shelf modules work for some, but most innovative products require specific modifications. A competent lcd display factory must offer deep customization options (ODM/OEM services).

This goes beyond just changing the size of the screen. You need to consider the FPC (Flexible Printed Circuit) shape and interface. Does your motherboard require a MIPI, SPI, MCU, or RGB interface? Your display partner needs to modify the FPC to match your hardware layout.

Backlight customization is another critical area. If your device is used outdoors, standard 250-nit brightness will wash out. You need a partner capable of engineering high-brightness solutions (sunlight readable) up to 1000 nits or more, without causing overheating issues.

Chuanhang Display specializes in these engineering challenges. We work with clients to adjust pin definitions, backlight intensity, and even touch panel integration (Capacitive vs. Resistive) to ensure the module fits the final housing perfectly.

Every manufacturer claims to have "good quality," but you need to ask for their specific testing protocols. A rigorous Quality Assurance (QA) process involves much more than just turning the screen on to see if it lights up.

Ask about their reliability testing lab. A professional lcd display factory will conduct environmental stress tests. This includes high and low-temperature storage testing (often ranging from -30°C to +80°C) and operation testing.

Humidity testing is equally important, especially for industrial or marine applications. Salt spray testing is necessary if the displays will be used in coastal or harsh environments.

Drop tests and vibration tests ensure the ruggedness of the module. If the factory cannot provide reports on these specific metrics, they may be skipping steps that protect your brand reputation.

The electronics industry is volatile. Shortages of Driver ICs or glass substrates can halt production lines globally. When vetting a supplier, you must evaluate their supply chain resilience.

Established factories have long-term relationships with major upstream suppliers for glass (like BOE, AUO, or Innolux) and driver ICs. This priority access is crucial during market shortages.

Ask about their standard lead times for samples versus mass production. A typical timeline might be 1-2 weeks for samples and 4-6 weeks for mass production. If a supplier promises unrealistic speeds, be wary of where they are cutting corners. Chuanhang Display focuses on transparent communication regarding lead times, ensuring our clients can plan their inventory accurately.

An LCD used in a consumer toy has different requirements than one used in a medical ventilator. It is beneficial to choose a factory that has experience in your specific vertical.

Industrial Control:Screens here need longevity. The product lifecycle might be 5 to 7 years. You cannot have the factory discontinue the screen model after 18 months. Stability is key.

Automotive:These require strict adherence to standards like IATF 16949. The displays must withstand extreme temperature fluctuations and vibration while maintaining perfect readability.

Medical:High contrast and absolute reliability are non-negotiable. There is no room for glitches in critical care equipment.

Smart Home:Here, aesthetics and touch response are paramount. The cover glass needs to look sleek, often requiring custom printing or anti-fingerprint coatings.

By understanding these sector-specific needs, a factory can offer proactive advice rather than just taking orders.

A consultative manufacturer will help you choose the right technology for your budget and application.

TN (Twisted Nematic):Cost-effective and fast response times. However, viewing angles are poor. Good for simple meters or budget devices.

IPS (In-Plane Switching):The industry standard for most modern devices. It offers wide viewing angles (80/80/80/80 degrees) and accurate color reproduction.

AMOLED:Offers true blacks and vibrant colors as individual pixels emit light. However, it is more expensive and can suffer from burn-in over long periods of static display.

At Chuanhang Display, we guide clients through these trade-offs. If you are building a budget-friendly thermostat, a TN panel might suffice. If you are building a premium dashboard, IPS is likely the necessary choice.

Modern displays are rarely just for viewing; they are for interaction. The bonding of the Touch Panel (TP) to the LCD is a critical manufacturing step.

There are two main types of bonding:

Air Bonding (Tape Bonding): Cheaper, but leaves a small air gap between the touch glass and the LCD. This can cause reflections in bright light.Optical Bonding: Uses a specialized resin to glue the glass directly to the LCD, eliminating the air gap. This improves durability and readability significantly but costs more.

A capable lcd display factory should offer both options. Optical bonding requires advanced machinery and clean room environments to prevent bubbles, which is a core competency at our facilities.

Selling products globally requires adherence to international standards. Your display supplier must be compliant with RoHS (Restriction of Hazardous Substances) and REACH.

If your product enters the European or American markets, non-compliance in the display component can lead to customs seizures or legal actions. Always request the SGS reports or compliance certificates for the raw materials used in the display modules.

ISO 9001 certification is the baseline for quality management. It proves the factory has a documented process for handling production and errors.

The relationship does not end when the goods are shipped. Electronic components can have latent defects. You need to know the RMA (Return Merchandise Authorization) policy.

A standard warranty in the industry is 12 months. However, the process is what matters. Does the factory analyze the failure to prevent recurrence (8D report)? Or do they simply ignore the issue?

Chuanhang Display prides itself on detailed failure analysis. If a screen fails in the field, our engineers want to know why—whether it was a manufacturing defect or an integration issue on the client side—to ensure it doesn't happen again.

Navigating the sea of suppliers in China can be overwhelming. Chuanhang Display stands out by combining the agility of a custom shop with the rigor of a large-scale manufacturer. We don't just sell part numbers; we sell visual solutions.

From the initial drawing board, where we assist with driver code and pinout design, to the final packaging that ensures safe transit, our team is aligned with your business goals. We understand that our display is the face of your brand.

Selecting the right partner is a strategic decision that impacts your product's pricing, quality, and time-to-market. By focusing on manufacturing infrastructure, quality control protocols, and engineering flexibility, you can filter out traders and find a true manufacturer.

Whether you need a high-brightness display for an outdoor kiosk or a precise touch screen for a medical device, the right lcd display factory makes the difference between a good product and a great one. We invite you to contact Chuanhang Display to discuss how we can bring your visual requirements to life.

Q1: What is the typical Minimum Order Quantity (MOQ) for a custom LCD project?

A1: MOQs vary depending on the complexity of the customization. For standard modules, the MOQ can be low (e.g., 100-500 units). For fully custom LCDs requiring new tooling (glass or backlight changes), the MOQ usually starts at 1,000 units to amortize the engineering costs effectively. Chuanhang Display strives to support startups and offers flexible policies for prototype runs.

Q2: How long does it take to develop a custom LCD module?

A2: Generally, the process takes about 3 to 5 weeks. This includes 1 week for drawing design and confirmation, and 2-4 weeks for tooling and sample production. Once samples are approved, mass production lead times typically range from 4 to 6 weeks depending on material availability.

Q3: Can you provide sunlight-readable displays for outdoor use?

A3: Yes. Standard screens typically range from 200 to 350 nits. For outdoor readability, we modify the backlight structure to achieve brightness levels between 800 and 1500 nits. We also recommend optical bonding and anti-glare (AG) coatings on the cover glass to further enhance visibility in direct sunlight.

Q4: What interface options are available for small to medium-sized TFT LCDs?

A4: The most common interfaces include MCU, SPI, and RGB for smaller, lower-resolution screens. For higher resolution displays (typically 4 inches and above), MIPI (Mobile Industry Processor Interface) and LVDS (Low-Voltage Differential Signaling) are standard. We can also assist with HDMI converter boards if you are connecting to a PC or Raspberry Pi.

Q5: How do you handle defective units or warranty claims?

A5: We offer a standard 12-month warranty on our products. If you encounter defective units, we request photos or samples of the failure for analysis. If the defect is determined to be a manufacturing error, we will replace the units or provide credit. We also provide an 8D report to explain the root cause and the corrective actions taken to prevent future occurrences.