In the fast-paced world of display technology, high-resolution touchscreens often grab the headlines. However, for engineers designing industrial interfaces, medical equipment, and robust metering systems, the Character LCD Module remains an undisputed champion.

It is easy to assume that newer is always better. But when a device needs to run for ten years in a dusty factory or operate on a minimal battery budget, complex graphical screens can be a liability. The character module offers a blend of simplicity, durability, and cost-effectiveness that is hard to beat.

At Chuanhang Display, we work with clients every day who realize that for transmitting alphanumeric data, this technology is not just sufficient—it is superior. This article looks at the technical reasons why these modules persist and how to select the right one for your application.

The fundamental job of a display is communication. While a color TFT screen can show video, many devices only need to show text. A thermostat needs to show numbers. A server rack needs to show status codes.

A Character LCD Module is purpose-built for this. It displays pre-defined letters, numbers, and symbols in a fixed grid. This focus on text allows for a very low processing overhead. The system's main processor does not need to render pixels or manage a frame buffer. It simply sends the ASCII code for the letter "A," and the module handles the rest.

This efficiency translates to system stability. There is less code to write and fewer bugs to squash. For safety-critical systems, this simplicity is a major safety feature.

To appreciate this component, you have to look at how it is built. These modules typically consist of a liquid crystal glass panel, a metal bezel, a PCB, and a controller IC.

The most famous standard in this space is the HD44780 controller protocol. Although the original chips have evolved, the command structure remains the industry standard. This means a Character LCD Module bought today acts almost exactly like one from twenty years ago. This backward compatibility is vital for long-term industrial maintenance.

The text is formed using a dot matrix. A standard character is usually a 5x8 pixel grid. This is enough resolution to distinguish between a "5" and an "S" clearly. The pixels are driven by the controller, which contains a built-in font table known as the CGROM (Character Generator Read Only Memory).

When sourcing a module, you must check the font table. Most standard modules come with English and Japanese characters (Katakana). However, at Chuanhang Display, we frequently supply modules with European, Cyrillic, or Hebrew font tables.

If your product is shipping to Russia or Greece, the standard font set will not work. You need a module with the correct ROM burned into the controller. This is a hardware decision, not a software one, so it must be made early in the design phase.

Why do engineers still specify these screens in 2024 and beyond? The advantages are practical and financial.

This is perhaps the biggest selling point. A TFT screen requires a powerful backlight and constant refreshing, consuming hundreds of milliamps. A character LCD, especially in a reflective mode without a backlight, consumes microamps.

For battery-powered handheld tools, this difference is massive. It allows a device to run on a coin cell battery for months. Even with a backlight, the power draw is predictable and low.

Complex screens often struggle in direct sunlight. They wash out. A Character LCD Module with a transflective or reflective polarizer actually gets easier to read the brighter the sun gets.

For outdoor equipment, such as irrigation controllers or marine gauges, this is non-negotiable. The user needs to see the data at noon just as clearly as they do at midnight.

Integrating these displays is straightforward. The libraries for communicating with them exist for almost every microcontroller on the planet, from 8-bit chips to advanced ARM processors.

There is no need to manage complex timing signals or high-speed data lanes. A few digital pins are usually all it takes to get text on the screen.

Historically, these modules used a parallel interface. This usually involved 4 or 8 data lines, plus control lines like Enable, Read/Write, and Register Select.

While robust, this method uses a lot of pins on the microcontroller. In modern designs, pin count is often at a premium.

Today, many engineers prefer a Character LCD Module equipped with a serial interface. Using an I2C expander chip (often mounted directly on the back of the module), the connection drops to just two wires: SDA and SCL.

This frees up the rest of the microcontroller’s pins for sensors and actuators. Chuanhang Display offers both native serial modules and "backpack" adapters that convert standard parallel modules to I2C, giving designers flexibility.

The physical form factor of character displays is highly standardized. The most common size is the 16x2 (16 characters per line, 2 lines).

However, many other configurations exist:

8x1: Very compact, for tight spaces.20x4: Offers significantly more information density.40x2: A wide format often used in rack-mounted audio gear.

The standard mounting holes and bezel dimensions mean you can often switch suppliers without redesigning your enclosure. This protects your supply chain. If one vendor has a shortage, you can swap in a compatible part.

Most traditional modules use Chip-On-Board construction. The controller IC is encapsulated in a black blob of epoxy on the PCB. This is extremely durable and moisture-resistant.

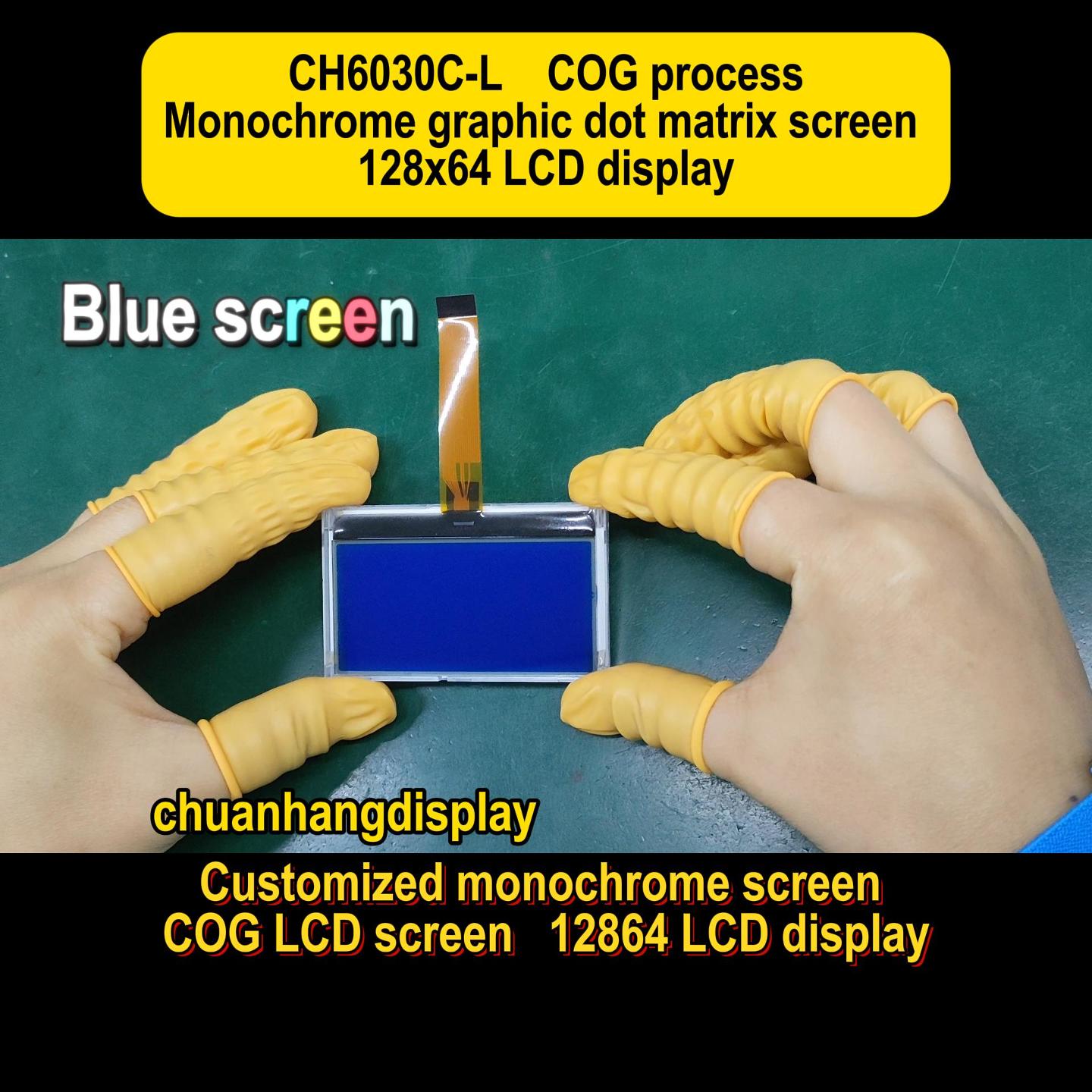

For thinner devices, Chip-On-Glass is an alternative. The controller sits directly on the glass edge. These modules are much thinner and lighter, though they can be slightly more fragile during assembly.

Just because the technology is established does not mean it has to look boring. The visual impact of a Character LCD Module is defined by two things: the liquid crystal mode and the backlight color.

STN (Super Twisted Nematic): The standard workhorse. Usually creates a yellow-green background with dark blue text.FSTN (Film Compensated STN): Offers higher contrast. It produces black text on a white/gray background.Negative Mode: This creates light text on a dark background. When paired with a backlight, this looks very modern and sleek.

The backlight is usually an LED array. While yellow-green is the classic "industrial" look, white and blue backlights are now standard for consumer-facing products.

Chuanhang Display can also provide RGB backlights. This allows the system to change the screen color based on status. The screen can be green during normal operation and turn red when a fault is detected. This adds a layer of user feedback without adding extra LEDs to the dashboard.

Working with these modules is generally smooth, but there are common pitfalls to avoid.

Every Character LCD Module has a pin usually labeled "V0" or "VO". This controls the contrast voltage. A common mistake is leaving this floating or connecting it incorrectly.

If the voltage is wrong, the screen will appear completely blank or completely black boxes. In a production environment, this is usually handled by a fixed resistor divider, but during prototyping, a potentiometer is essential to find the "sweet spot."

LCDs have a preferred viewing angle. This is usually defined as 6:00 (viewed from below) or 12:00 (viewed from above).

If you mount a 6:00 display on a device that sits flat on a desk, the user might look at it from a 12:00 angle and see a washed-out image. It is critical to define where the user’s eyes will be relative to the screen before ordering.

Standard displays work well in office environments. But if your device sits in a car dashboard in Arizona or a pumping station in Alaska, the fluid can freeze or turn isotropic (black).

Wide-temperature fluids are available. They include heaters or special chemical mixtures to maintain viscosity in the cold and prevent clearing in the heat.

Quality control for character modules focuses on the integrity of the seal and the connection of the pins.

We use automated visual inspection to ensure that every segment of the dot matrix fires correctly. We also perform vibration testing. Since these modules often use "zebra strips" (elastomeric connectors) to link the glass to the PCB, ensuring proper compression is vital.

If the compression is too loose, segments will drop out. If it is too tight, the glass might stress fracture. Our manufacturing tolerances are tight to prevent these field failures.

While these are "character" displays, they are not strictly limited to letters. The controller typically has a small amount of RAM called CGRAM (Character Generator RAM).

This allows the user to define up to 8 custom symbols. You can draw a battery icon, a tiny logo, or a specific scientific symbol pixel-by-pixel.

This feature bridges the gap between text-only and fully graphic displays. It allows for a customized user interface experience without the cost of a graphic panel.

One concern engineers have is availability. Will these screens exist in 10 years?

The answer is yes. The volume of industrial, automotive, and appliance products that rely on the Character LCD Module ensures a robust supply chain. Unlike smartphone screens that change every year, the 16x2 form factor is an industrial standard.

By designing this component into your product, you are insulating yourself from the volatility of the consumer electronics market. You are choosing stability.

In an era of obsession with 4K resolution and OLEDs, the humble character display remains the backbone of the industrial world. It does one thing, and it does it perfectly: it communicates data reliably.

It tolerates temperature extremes, sips power, and resists electrical noise. For engineers who value function and longevity, it is often the smartest choice.

At Chuanhang Display, we understand the nuances of this technology. We help you choose the right viewing angle, the right interface, and the right temperature range to ensure your product performs flawlessly. Whether you need a standard off-the-shelf part or a customized solution, the Character LCD Module is a technology you can trust for the long haul.

Q1: What does the "16x2" designation mean for a Character LCD Module?

A1: The numbers refer to the layout of the characters. "16x2" means the display can show 16 characters per horizontal line, and it has 2 vertical lines. This creates a total capacity of 32 characters on the screen at one time. Other common sizes include 20x4 (20 characters, 4 lines) and 8x1.

Q2: My display is showing only black boxes on the first line. What is wrong?

A2: This is a very common issue. It usually indicates that the module is receiving power but has not been initialized correctly by the software. It can also mean the contrast voltage (V0 pin) is set too high. Check your initialization code and adjust the contrast potentiometer to resolve this.

Q3: Can I use a Character LCD Module in a dark environment?

A3: Yes, but you must select a module with a backlight. Transmissive and Transflective modules allow light to pass through the glass. You can choose from various LED colors like white, blue, or yellow-green to ensure the text is legible in total darkness.

Q4: What is the difference between parallel and I2C connections for these modules?

A4: A parallel connection uses multiple pins (usually 6 to 10) on your microcontroller to send data. An I2C connection uses an additional interface chip to allow communication over just two wires (SDA and SCL). I2C is preferred when you need to save pins for other components.

Q5: How do I display a symbol that is not in the standard alphabet, like a smiley face or a battery icon?

A5: You can use the CGRAM (Character Generator RAM). The controller allows you to define a small number (usually 8) of custom characters. You program the pixel pattern for your icon into the memory, and you can then call it up just like a regular letter.