Visual communication is central to modern electronics design. While simple text displays serve a purpose, complex machines often require charts, icons, and variable font sizes to convey information effectively. This is where the graphic LCD becomes an essential component. Unlike fixed-segment displays that only show alphanumeric characters, a graphic module gives you control over every individual pixel on the screen. This pixel-level control allows engineers to create custom user interfaces that are both functional and intuitive.

For decades, these displays have been the standard interface for medical devices, industrial controllers, and audio equipment. They bridge the gap between simple status indicators and high-power color screens. You do not need a high-end operating system to run them. A standard microcontroller is usually sufficient to drive a graphic LCD, making them a cost-effective solution for embedded systems.

Choosing the right module involves understanding resolution, controller types, and viewing angles. The market is filled with options, but quality varies significantly. Manufacturers like Chuanhang Display have carved out a reputation for producing high-reliability screens that maintain contrast and performance over long operational lifespans. This article explores the technology, integration methods, and best practices for deploying these versatile displays.

The primary difference lies in the architecture of the pixel grid. A character display has physically separated blocks of pixels. A graphic LCD, however, is a continuous matrix of dots. For example, a common 128x64 resolution screen contains 8,192 individual pixels arranged in a grid.

This structure offers immense flexibility. You are not limited to built-in fonts. You can draw lines, circles, company logos, and even simple animations. This capability is vital for devices that need to display waveforms, battery level icons, or multi-language support including non-Latin scripts like Chinese or Arabic.

Key advantages include:

Customization: Draw anything the resolution allows.Versatility: Mix text of various sizes with images.Simplicity: Easier to drive than full-color TFTs.Power Efficiency: Excellent battery life for portable tools.

The visual performance of your screen depends on the liquid crystal fluid technology. Understanding these types helps you predict how the graphic LCD will look in different lighting conditions.

STN (Super Twisted Nematic)STN is the workhorse of the industry. It offers a reasonable balance between cost and performance. You typically see these in two variations: Yellow-Green mode (black pixels on a yellow-green background) and Blue mode (white pixels on a blue background). The Yellow-Green mode is incredibly efficient because the backlight is optional in bright rooms.

FSTN (Film Compensated STN)If your project requires high contrast, FSTN is the superior choice. It adds a compensation film to the glass stack. This turns the background white and the pixels deep black. The result is a sharp, crisp image that looks professional. FSTN is often preferred for medical instruments where readability is critical.

Reflective vs. Transmissive

Reflective: Uses ambient light. Great for outdoors.Transmissive: Requires a backlight. Best for dark environments.Transflective: The hybrid approach. It reflects sunlight but also allows the backlight to shine through. This is the ideal choice for an all-weather graphic LCD.

While you can find custom sizes, the industry has standardized around a few key resolutions. Sticking to these standards ensures better availability and easier software development.

128x64 DotsThis is the most ubiquitous size. It provides enough space for a menu system and a header bar. It is compact enough for handheld multimeters or smart thermostats. Libraries for this resolution are widely available for almost every microcontroller.

240x64 DotsThis "wide" format is popular in rack-mounted audio gear and server appliances. It allows for long strings of text or wide timelines without making the device too tall.

240x128 DotsThis is the big brother of the standard graphic LCD. It offers four times the pixels of a 128x64 screen. It is commonly found on CNC machine controllers and complex industrial interfaces where the operator needs to see multiple data points simultaneously.

Companies like Chuanhang Display offer these standard resolutions with consistent pinouts. This consistency means you can upgrade a legacy product without redesigning your entire printed circuit board.

The "brain" of the graphic LCD is the controller chip mounted on the glass or the PCB. This chip manages the refresh rate and pixel data. Your microcontroller talks to this chip, not the pixels directly.

Common Controllers

KS0108: The classic parallel controller for 128x64 screens. Reliable but requires many wires.ST7920: Popular because it supports both parallel and serial (SPI) modes. It also has a built-in Chinese font set in some variations.ST7565: A common choice for smaller, low-power displays, often used with SPI.

Communication Protocols

8080/6800 Parallel: Fast data transfer. Requires 8 data pins plus control lines. Good for high-refresh animations.SPI (Serial Peripheral Interface): Uses only 3 or 4 wires. Slower than parallel but saves microcontroller pins.I2C: The most pin-efficient method (2 wires), though slower.

Choosing the right interface is a trade-off. If you need to update the entire screen instantly, parallel is best. If you need to save pins for sensors, SPI is the smarter route for your graphic LCD integration.

Hardware is only half the battle. To draw on a graphic LCD, you need software drivers. Writing raw pixel data to memory addresses can be tedious, so most engineers use graphics libraries.

The Buffer ConceptMost libraries use a "frame buffer" approach. The microcontroller allocates a chunk of RAM that mirrors the screen's pixels. You draw lines and text into this RAM buffer, and then send the whole buffer to the display.

Popular Libraries

u8g2: A powerhouse library for Arduino and embedded C. It supports hundreds of controller types.GLCD: An older but stable library specifically for KS0108 modules.Vendor Drivers: High-quality suppliers often provide initialization code. Chuanhang Display provides sample code for their modules, which speeds up the "bring-up" phase significantly.

Font HandlingOne challenge is fonts. Since the screen is just pixels, you must define the bitmap for every letter. Libraries usually include standard fixed-width and variable-width fonts. Storing large fonts can consume microcontroller memory, so efficient coding is required.

Efficiency is a major selling point for the monochrome graphic LCD. Without the backlight, the logic circuits consume microamps. This makes them suitable for battery-operated devices that must run for months or years.

Backlight ConsiderationsThe backlight is the power-hungry part. A typical LED array might draw 20mA to 100mA.

PWM Control: Use Pulse Width Modulation to dim the backlight. You rarely need 100% brightness indoors.Timeout: Implement a software timer to turn off the light after 30 seconds of inactivity.

Contrast VoltageUnlike modern phone screens, these displays need a negative voltage to bias the crystals. Many modules include a built-in DC-DC converter to generate this negative voltage from a standard 3.3V or 5V supply. However, you often need to adjust the contrast externally using a potentiometer connected to the V0 or VEE pin.

Consumer gadgets can be fragile, but industrial tools must be tough. A graphic LCD is inherently robust, but environmental specs matter.

Temperature RangeLiquid crystals freeze in extreme cold and turn black in extreme heat.

Standard Temp: 0°C to +50°C (Office environments).Wide Temp: -20°C to +70°C (Outdoor/Industrial).If you are designing a dashboard for a snowmobile or a solar inverter in the desert, you must specify a wide-temperature module.

UV ProtectionProlonged exposure to direct sunlight can damage the polarizing film, causing "sunburn" on the display. Industrial-grade modules often feature UV-resistant polarizers to prevent this yellowing effect.

Vibration ResistanceThe connection between the glass and the PCB is critical. Zebra strips (elastomeric connectors) are common but can shift under high vibration. For high-vibration environments, modules with heat-sealed (FPC) connections or soldered pins are more reliable.

In an era of 4K OLEDs, the humble dot matrix screen persists. Why? Reliability and focus. A color screen can be a distraction. It complicates the certification process for medical and aviation devices. A monochrome graphic LCD presents data without clutter.

Furthermore, supply chain stability is crucial for industrial products. A specific OLED panel might vanish from the market in six months. Standard graphic modules, however, have remained mechanically and electrically compatible for twenty years. Manufacturers like Chuanhang Display understand this long-term commitment. They support legacy designs, ensuring that a machine built in 2010 can still be repaired today.

Cost EffectivenessThe cost of the screen is low, but the cost of the system is also lower. You do not need a dedicated GPU or high-speed RAM. A 50-cent microcontroller can drive the display, reducing the overall Bill of Materials (BOM) cost.

The graphic LCD remains a cornerstone of embedded design. It strikes a perfect balance between visual capability and system simplicity. Whether you are displaying a patient's heart rate or the RPM of a turbine, these modules provide the clarity and control engineers demand.

Success lies in the details. Selecting the right fluid technology (FSTN vs. STN), choosing the correct interface (SPI vs. Parallel), and managing power consumption are all critical steps. It is also a reminder that the source of your components matters. Partnering with dedicated manufacturers like Chuanhang Display ensures you receive modules that meet rigorous industrial standards, minimizing failure rates in the field.

By leveraging the pixel-level control of these displays, you can build interfaces that are robust, responsive, and perfectly tailored to your application's needs.

Q1: Can I display images on a monochrome graphic LCD?

A1: Yes, you can display images, but they must be converted to a 1-bit bitmap format. Since pixels are either on or off, you cannot show greyscale directly. To simulate shades of grey, you must use dithering techniques, which arrange pixels in patterns to create the illusion of shading.

Q2: My graphic LCD is showing random noise on startup. What is wrong?

A2: This is normal behavior for the hardware. The RAM inside the display controller starts with random values when power is applied. Your startup code must essentially "clear" the screen by writing zeros to every memory address in the display buffer before turning on the display output.

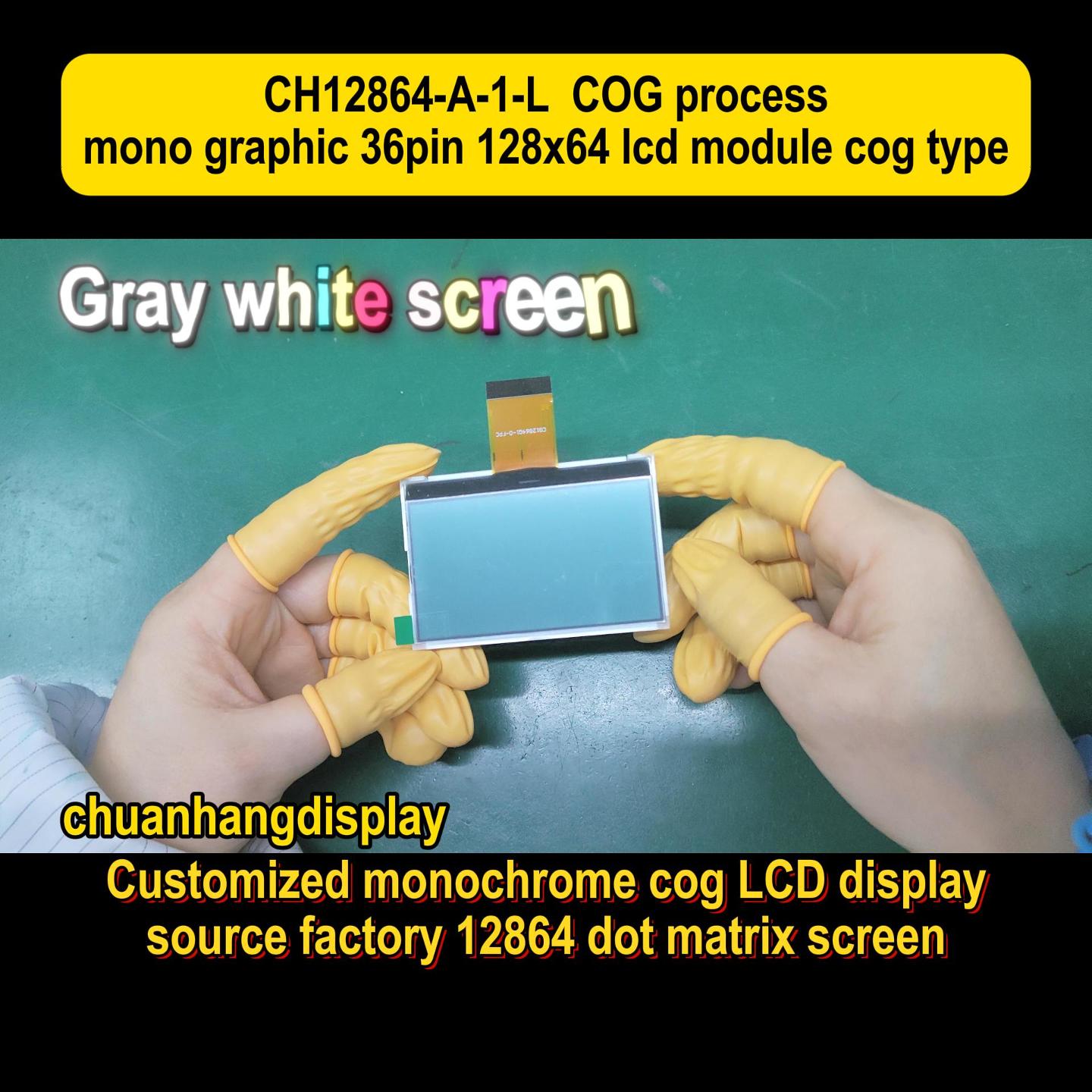

Q3: What is the difference between COB and COG construction?

A3: COB (Chip On Board) places the controller chip on the PCB, making the module thicker and larger but very sturdy. COG (Chip On Glass) mounts the controller directly onto the edge of the glass. COG modules are much thinner and lighter, making them ideal for compact, handheld devices.

Q4: How do I handle multiple languages on a graphic LCD?

A4: Unlike character LCDs which have a fixed font ROM, a graphic LCD draws pixels. You need to store the font data (bitmaps of letters) in your microcontroller's flash memory. To support languages like Chinese or Japanese, you will need a large flash memory to store the thousands of characters required, or use a module with a built-in font chip (like the ST7920).

Q5: Why is the contrast changing when the temperature drops?

A5: The viscosity of the liquid crystal fluid changes with temperature. As it gets colder, the fluid moves slower and the contrast voltage requirements change. In outdoor applications, it is common to implement "temperature compensation," where the software adjusts the contrast voltage automatically based on a temperature sensor reading.