Bringing a new electronic product to life involves a myriad of design choices, but few are as visible as the screen. It is the face of the device. While standard off-the-shelf modules are plentiful, they rarely fit the specific mechanical or optical requirements of a unique new product. This is where a custom lcd becomes not just an option, but a necessity.

Engineers often hesitate to pursue customization due to fears of high costs or long lead times. However, the display industry has evolved. Manufacturing processes are now flexible enough to allow for modifications ranging from simple cable changes to fully unique glass sizes. Understanding how to navigate this process is key to building a superior product without breaking the budget.

When to Move Beyond Standard Modules

The decision to commission a custom lcd usually stems from mechanical constraints or environmental demands. A standard 5-inch screen might have a viewing area that is perfect, but the Flexible Printed Circuit (FPC) might be too short to reach your motherboard. Or perhaps the standard backlight isn't bright enough for your outdoor application.

In industrial design, space is a premium. Using a standard screen often forces the housing to be larger than necessary to accommodate unused bezel space. A custom solution allows the display to conform to the product, rather than the product conforming to the display. This is particularly critical in wearable technology, medical handhelds, and automotive dashboards where every millimeter counts.

The Spectrum of Customization

Many buyers assume customization is an "all or nothing" scenario. In reality, it exists on a spectrum. Understanding where your project falls can save significant development time and money.

Semi-Customization

This is the most common route. Here, the core LCD cell (the glass layer) remains standard, but the surrounding components are altered. You might change the interface from RGB to LVDS, modify the FPC shape, or upgrade the backlight unit for higher brightness. This approach requires minimal tooling fees and is faster to produce.

Full Customization

This involves creating a new mask for the LCD glass itself. This is necessary if you need a non-standard aspect ratio, a unique icon display for a dashboard, or a specific segment layout. While this offers total design freedom, it involves higher Non-Recurring Engineering (NRE) costs and longer lead times for the initial samples.

Technical Deep Dive: The Interface and FPC

One of the most frequent technical reasons to build a custom lcd is the connection interface. The FPC is the bridge between the display and your device's brain. Standard modules often come with a rigid pin definition that might conflict with your existing PCB layout.

Designing a custom FPC allows you to rearrange the pinout sequence. You can route power and ground lines to match your board, eliminating the need for a messy adapter board. Furthermore, you can integrate other components directly onto the FPC.

For example, many modern designs place the capacitive touch controller IC or even the backlight driver circuit directly on the FPC tail. This reduces the component count on your main motherboard and simplifies the overall assembly process. Signal integrity is also improved, as you can specify shielded FPC materials to prevent electromagnetic interference (EMI) in sensitive environments.

Brightness and Optical Performance

Outdoor visibility is a major challenge for standard screens. A typical indoor display outputs between 250 and 350 nits of brightness. Under direct sunlight, this appears completely black.

When developing a custom lcd, you can specify the backlight composition. By using high-efficiency LEDs and specialized optical films (such as dual brightness enhancement films), manufacturers can boost brightness to 1000 nits or more without significantly increasing power consumption.

Beyond brightness, the viewing angle technology is a critical choice. For cost-sensitive projects, Twisted Nematic (TN) panels are effective but suffer from color inversion when viewed from sharp angles. For devices that will be moved or viewed by multiple people simultaneously, specifying In-Plane Switching (IPS) technology ensures the colors remain accurate from any direction.

The Financials: NRE and Unit Pricing

Cost is always the elephant in the room. There is a misconception that custom displays are exponentially more expensive than standard ones. While the upfront investment is higher, the unit price can sometimes be lower because you are removing features you don't need.

Non-Recurring Engineering (NRE)

This is the one-time fee to set up the manufacturing line.

Backlight/FPC Tooling: usually ranges from a few hundred to a couple of thousand dollars.

Touch Panel Tooling: depends on the size and complexity, generally moderate.

LCD Glass Tooling: This is the most expensive part, required only for full custom lcd glass shapes.

Most suppliers have a refund policy. If your total order volume reaches a certain threshold (e.g., 50k or 100k units) over a year or two, the NRE fee is often returned to the buyer. This amortizes the development cost over the product's lifecycle.

Touch Integration and Cover Lenses

Modern user interfaces expect touch. Integrating a touch panel is a standard part of the customization process. You have two main technologies: Resistive (pressure-based, good for gloves) and Capacitive (smartphone-style, supports multi-touch).

The cover lens—the glass on top—is where branding happens. You can customize the cover glass to be larger than the display area, creating a flush "tablet-like" look for your device. You can print your company logo directly on the glass, add cutout holes for physical buttons, or apply anti-glare (AG) and anti-fingerprint (AF) coatings.

A critical decision in this phase is the bonding method. Air bonding uses double-sided tape around the edges. It is cheap but leaves an air gap that can trap dust or cause reflections. Optical bonding uses a liquid resin (LOCA) or dry film (OCA) to glue the glass directly to the LCD. This eliminates reflections and dramatically improves durability, a service that Chuanhang Display specializes in for rugged applications.

Quality Control and Reliability

A custom lcd is not just about looks; it is about longevity. Standard consumer displays often have a lifecycle of 12 to 18 months before the manufacturer changes the design. This is a nightmare for medical or industrial products that need to be sold for 5 to 10 years.

When you create a custom part number, you lock in the Bill of Materials (BOM). The controller IC, the backlight LEDs, and the polarizer type remain consistent batch after batch.

Reliability testing is also tailored. If your device is for a vehicle, the display needs to survive -30°C to +80°C. If it is for a marine application, it needs salt-spray resistance. During the NRE phase, you define these parameters, and the manufacturer validates them before mass production begins.

Supply Chain Security

Global component shortages can stall production lines. Customizing your display can actually help mitigate this risk. By working with an engineering team, you can select Driver ICs that have stable stock levels rather than being forced to use the specific IC hard-coded into a standard module.

Furthermore, a dedicated manufacturer will often bank stock of critical raw materials for their custom clients. This creates a buffer against market volatility that isn't available when buying generic modules from a catalog distributor.

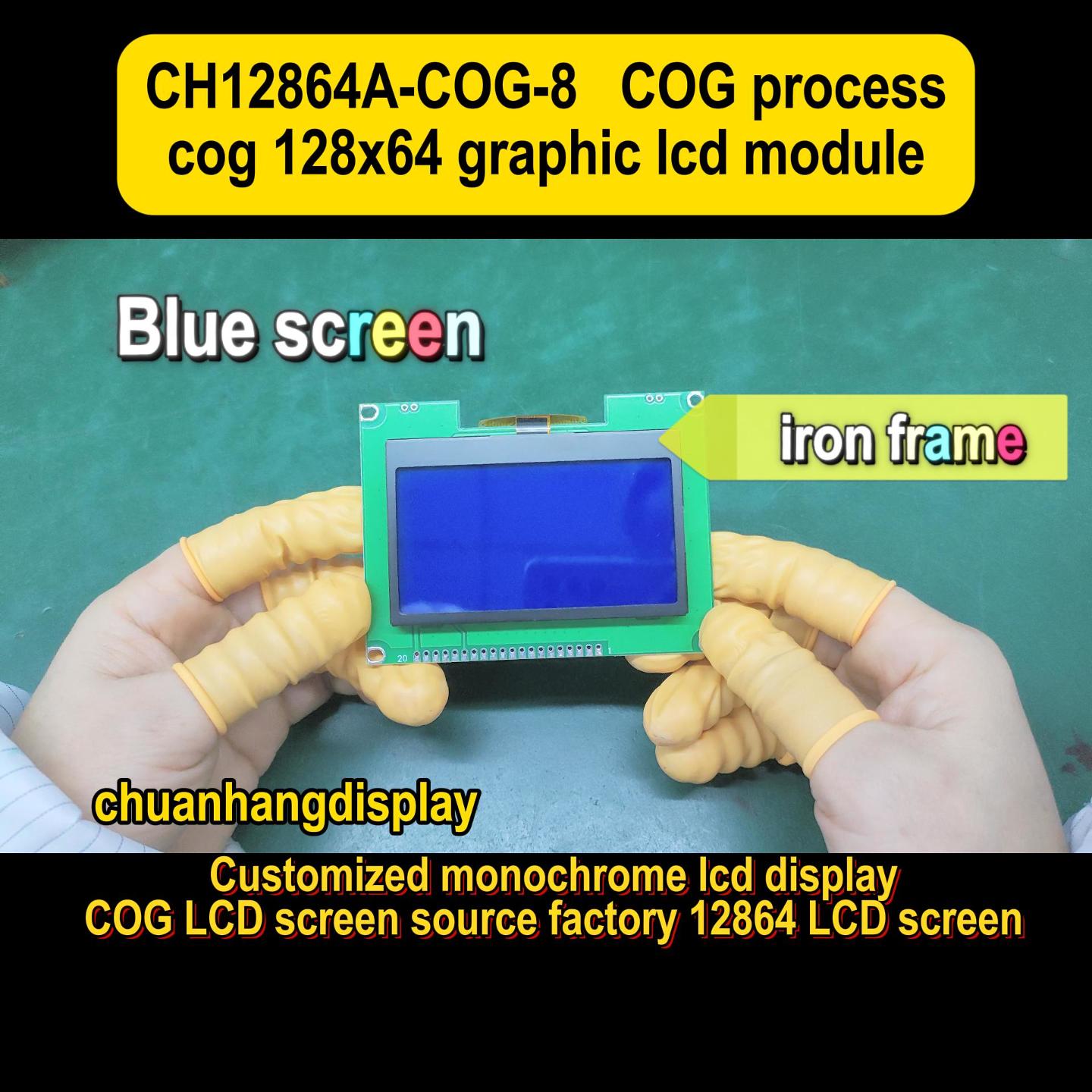

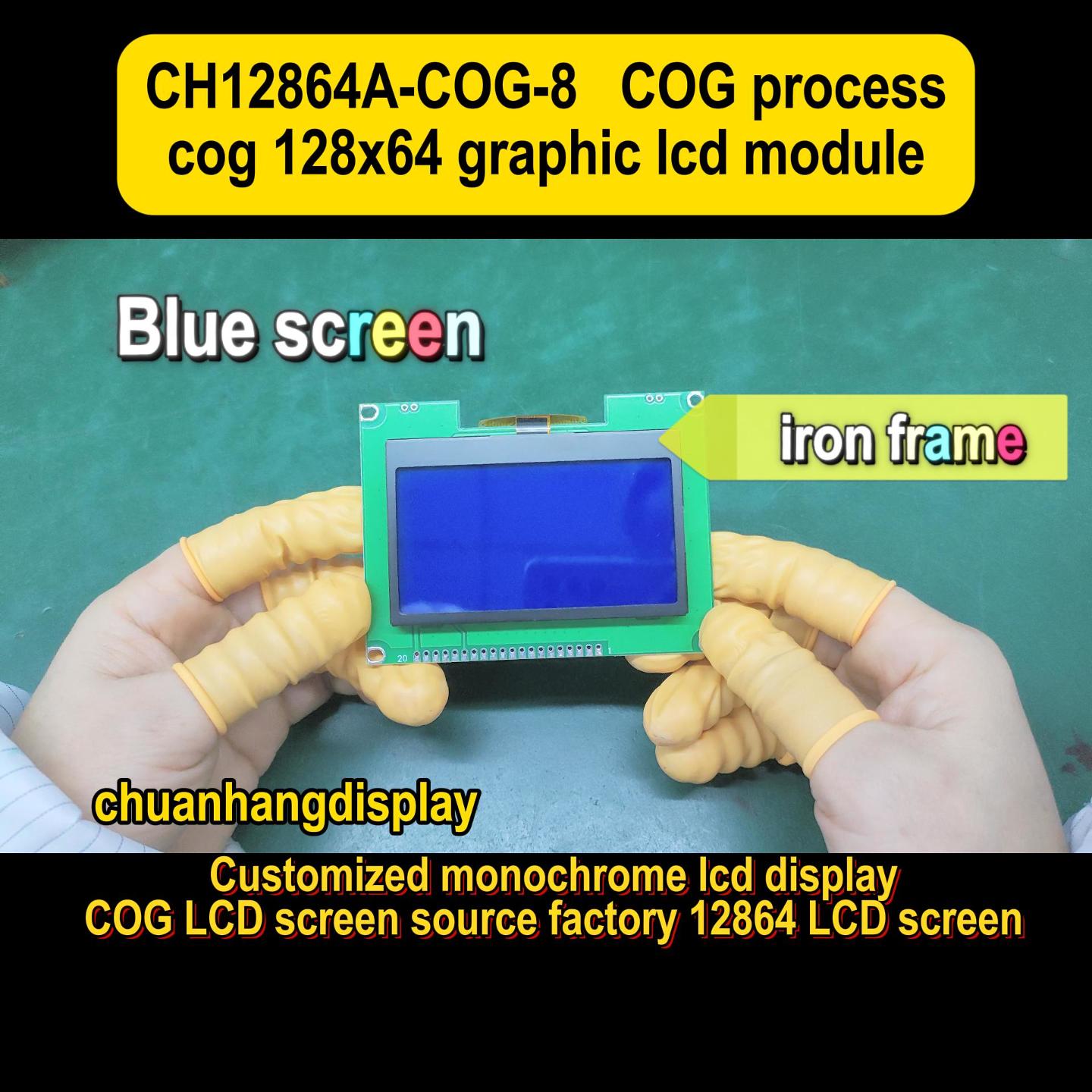

Partnering with Chuanhang Display

The success of a custom project relies heavily on the engineering communication between the buyer and the factory. This is where Chuanhang Display distinguishes itself. We do not just take orders; we act as consultants.

Many clients come to us with a rough idea—"I need a round screen for a smart knob"—and our team guides them through the trade-offs of resolution, interface speed, and cost. We specialize in small-to-medium-sized LCDs, a niche where attention to detail matters most.

Chuanhang Display offers a streamlined development path. We start with a counter-drawing based on your requirements. Once approved, we move to tooling and sample production. Our facility is equipped to handle complex assemblies, including the integration of custom touch panels and specialized backlights. We understand that for many businesses, a massive Minimum Order Quantity (MOQ) is a barrier. We work to offer flexible MOQs that allow your product to grow in the market

The transition from a standard screen to a custom lcd marks the maturation of a product design. It signals that the device is purpose-built, not just assembled from spare parts. While it requires upfront planning and a modest investment in tooling, the payoffs in aesthetics, functionality, and long-term supply stability are immense.

By controlling the specifications of your display, you ensure that the end-user sees exactly what you intended, in any lighting condition. Whether you are building the next generation of medical monitors or a smart home controller, the display is your primary interface. Partnering with an experienced manufacturer like Chuanhang Display ensures that this interface is robust, beautiful, and manufacturable.

Frequently Asked Questions

Q1: What is the typical lead time for a custom LCD project?

A1: The process generally starts with 3 to 5 days for engineering drawing design and approval. Once the drawing is confirmed, tooling and sample production typically take 15 to 20 days depending on complexity. Mass production lead times are usually around 4 to 6 weeks after sample approval.

Q2: Is the NRE (tooling fee) refundable?

A2: Yes, in most cases. While you pay the NRE upfront to cover the setup costs, reputable manufacturers like Chuanhang Display usually offer a refund policy. Once your total purchase volume reaches a specific agreed-upon quantity (e.g., 50,000 units), the tooling fee is returned or credited back to you.

Q3: Can I customize an LCD if my volume is low?

A3: It depends on the level of customization. For semi-custom changes (like FPC modification or backlight brightness adjustments), MOQs can be quite low, sometimes as few as 500 or 1,000 units. Full glass customization usually requires higher volumes to be cost-effective, but it is always worth discussing with the supplier.

Q4: What information do I need to provide to get a quote?

A4: To get an accurate quote for a custom lcd, provide the desired active area (screen size), resolution, interface type (e.g., RGB, MCU, MIPI), target brightness (in nits), and any touch panel requirements. If you have a datasheet of a standard screen you want to modify, that is the best starting point.

Q5: What is the difference between a custom backlight and a custom LCD panel?

A5: A custom LCD panel involves changing the actual glass dimensions and pixel structure, which is expensive and complex. A custom backlight involves changing the metal frame and LED rails behind the glass. Changing the backlight is a cost-effective way to change the mechanical shape of the module's housing or improve brightness without touching the expensive glass layer.