When designing industrial equipment, medical devices, or consumer electronics, the display interface is the primary bridge between the machine and the operator. While colorful touchscreens get a lot of attention, the humble character LCD remains a cornerstone of the electronics industry. Its reliability, low power consumption, and straightforward integration make it the preferred choice for thousands of applications worldwide.

At Chuanhang Display, we understand that selecting the right display module is not just about finding a part number. It is about matching optical characteristics and electrical specifications to the environment where the device will operate. This article breaks down the technical aspects of alphanumeric displays to help engineers and procurement managers make informed decisions.

A character LCD is a liquid crystal display specifically designed to show alphanumeric text and symbols. Unlike graphic displays that allow you to manipulate individual pixels across the entire screen to draw images, character modules utilize a fixed matrix.

Each character is usually formed by a 5x8 or 5x7 dot matrix within a predefined block. These blocks are arranged in rows and columns. The design focuses on displaying information clearly and efficiently without the processing overhead required for full graphic rendering.

The internal structure consists of the liquid crystal layer, the glass substrate, polarizers, and a backlight unit. However, what makes these modules distinct is the built-in controller. This onboard chip contains a Character Generator ROM (CGROM), which stores standard fonts (ASCII), and a Character Generator RAM (CGRAM), allowing users to define a few custom symbols.

In an era of high-definition OLEDs, one might ask why a simple alphanumeric screen is still relevant. The answer lies in efficiency and stability. A character LCD draws significantly less current than a TFT screen. For battery-operated handheld devices or industrial meters powered by loop current, this power saving is non-negotiable.

Readability is another major factor. These displays are available in various modes, including reflective types that rely on ambient light. This makes them perfectly legible in direct sunlight, a scenario where many modern backlit screens wash out completely.

Simplicity of code is also vital. Interfacing with these modules is standardized. An engineer does not need to write complex drivers or manage frame buffers. Sending a simple command to display the letter "A" is fast and requires minimal MCU resources.

The industry has settled on several standard sizes that fit most enclosures. The most ubiquitous format is the 16x2 display, meaning it shows two rows of sixteen characters each.

However, Chuanhang Display offers a wide variety of configurations to suit different mechanical constraints:

8x1 to 8x2: Compact sizes for small handheld meters.16x1 to 16x4: The standard for server racks, printers, and coffee machines.20x2 to 20x4: Ideal for industrial control panels requiring more status information.40x2 to 40x4: Large format displays for extensive data readout without paging.

Choosing the right format depends heavily on the "information density" your user interface requires. If your device only needs to show a temperature reading, a smaller module reduces cost and saves physical space.

Not all liquid crystal fluids are the same. The visual performance of a character LCD depends heavily on the fluid technology used.

TN (Twisted Nematic): This is the most basic and cost-effective option. It offers high contrast but has a narrower viewing angle. It is suitable for devices typically viewed from directly in front, such as utility meters.

STN (Super Twisted Nematic): This technology improves upon TN by twisting the crystal molecules at a greater angle. The result is a wider viewing angle and better contrast. STN displays are often identified by their characteristic background colors, such as Yellow-Green or Blue.

FSTN (Film Compensated STN): This is a premium option often recommended by Chuanhang Display for high-end equipment. It adds a retardation film to the STN layer to produce a black-and-white image. The contrast is sharp, and the readability is excellent.

The backlight determines how the display looks in low-light conditions. While LED backlights are the standard today due to their long life and low voltage, the configuration matters.

Transmissive: The backlight must be on for the content to be seen. These are bright and work well indoors but can struggle in direct sun.

Reflective: These have no backlight. They use a mirror layer to reflect ambient light. They are useless in the dark but offer the highest contrast in bright outdoor environments and consume the least power.

Transflective: This is the hybrid solution. It has a semi-transparent mirror. It reflects sunlight outdoors but allows the backlight to shine through in the dark. For portable outdoor equipment, a transflective character LCD is often the only viable specification.

Connecting the display to your microcontroller involves choosing an interface. The standard parallel interface (6800 or 8080 mode) has been used for decades. It typically requires 4 to 8 data lines plus control lines (RS, RW, E).

While the parallel interface is fast, it consumes many GPIO pins on the host microcontroller. Modern designs often favor serial communication to save pins for other sensors or controls.

Many modules from Chuanhang Display can be equipped with an I2C or SPI interface board. An I2C interface requires only two wires (SDA and SCL) plus power. This drastically simplifies the PCB layout and reduces the connector size. If your main board is crowded, moving to a serial interface character LCD is a smart engineering move.

Almost all alphanumeric displays follow a standard command set established by the Hitachi HD44780 controller. Even though the original chip is old, compatible modern equivalents like the Sitronix ST7066 or Samsung KS0066 are used today.

This standardization is a massive advantage. It means that if you source a standard 16x2 module, the software libraries you use (like the LiquidCrystal library for Arduino or standard drivers for STM32) will work immediately. You rarely need to write low-level driver code from scratch.

However, it is crucial to check the voltage logic. Older controllers operated strictly at 5V. Modern systems running at 3.3V may require a display module with a built-in charge pump or a low-voltage controller to ensure the contrast is correct without external level shifters.

Industrial electronics are often subjected to harsh environments. A standard consumer-grade screen might work fine at room temperature but will become sluggish in freezing conditions or turn black in extreme heat.

Standard temperature modules typically operate between 0°C and +50°C. For outdoor or industrial applications, you should specify a Wide Temperature character LCD.

Wide temperature range modules usually function from -20°C to +70°C. Some automotive-grade options go even further, from -30°C to +80°C. Chuanhang Display utilizes special liquid crystal fluids for these models to prevent the display from freezing or losing contrast when the temperature fluctuates.

During the prototyping phase, engineers often encounter a few distinct issues. Recognizing them early saves time.

If you see a row of black blocks on the top line and nothing on the bottom, your initialization sequence has likely failed, or the contrast voltage (V0) is incorrect. The contrast pin usually requires a potentiometer to dial in the voltage. If this pin is left floating, the text may be invisible.

If the screen displays garbage characters, check your timing. The liquid crystal controller is slower than a modern 100MHz microcontroller. If you send data too fast without checking the "Busy Flag" or adding delays, the display controller cannot keep up.

Ghosting occurs when the voltage is too high, while faint text indicates the voltage is too low. Adjusting the V0 bias is the fix for both.

While off-the-shelf parts cover 90% of use cases, sometimes a project requires specific modifications. Customization does not always mean creating a new glass panel from scratch.

Chuanhang Display provides semi-custom services. This includes changing the backlight color, swapping the connector type (e.g., from pin header to FPC cable), or soldering pre-configured headers for faster assembly.

For high-volume projects, we can create custom glass sizes, unique icons in the CGROM, or specific polarizer angles to fit the ergonomics of your final product housing.

The character LCD remains a vital component in the electronics supply chain. Its combination of low cost, high reliability, and sunlight readability ensures it will not be replaced by high-resolution screens in many sectors.

Whether you are building a medical ventilator, a CNC machine, or a handheld payment terminal, understanding the nuances of fluid types, interfaces, and operating temperatures is essential. By partnering with Chuanhang Display, you gain access to high-quality modules and the technical expertise required to integrate them seamlessly into your design.

Q1: What is the main difference between a character LCD and a graphic LCD?

A1: A character LCD has a pre-defined grid (usually 5x8 dots) meant solely for displaying text and numbers using a built-in font generator. A graphic LCD allows you to control every individual pixel on the screen, enabling you to draw curves, images, and different font sizes, but it requires more complex software and memory to drive.

Q2: Can I use a 5V display with a 3.3V microcontroller?

A2: It is risky to connect them directly. While the display might light up, the logic levels may not trigger correctly, and the contrast will likely be very poor. You should either use a logic level shifter and an external negative voltage for contrast, or simply request a 3.3V compatible module from Chuanhang Display which has the correct internal circuitry.

Q3: What is the viewing angle direction, and why does it matter?

A3: LCDs are optimized to be viewed from a specific angle, usually described like a clock face (6:00 or 12:00). A 6:00 viewing angle is best viewed from slightly below (like a wall thermostat), while 12:00 is best from above (like a device sitting on a desk). Choosing the wrong angle results in poor contrast for the user.

Q4: How long is the lifespan of the LED backlight?

A4: The half-life of a standard LED backlight in a character LCD is typically around 50,000 to 70,000 hours. This is the point at which the brightness degrades to 50% of its original intensity. This generally translates to many years of continuous operation.

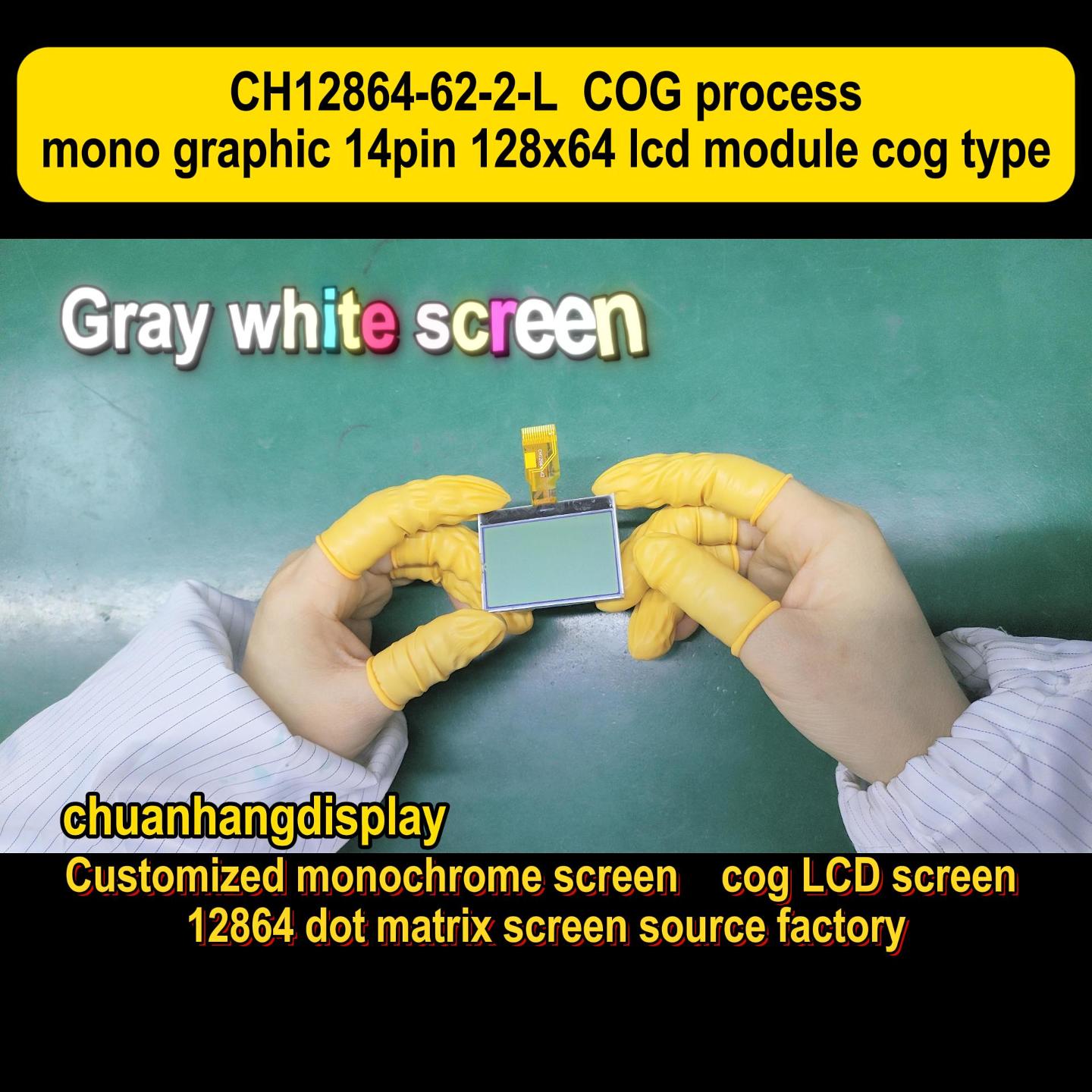

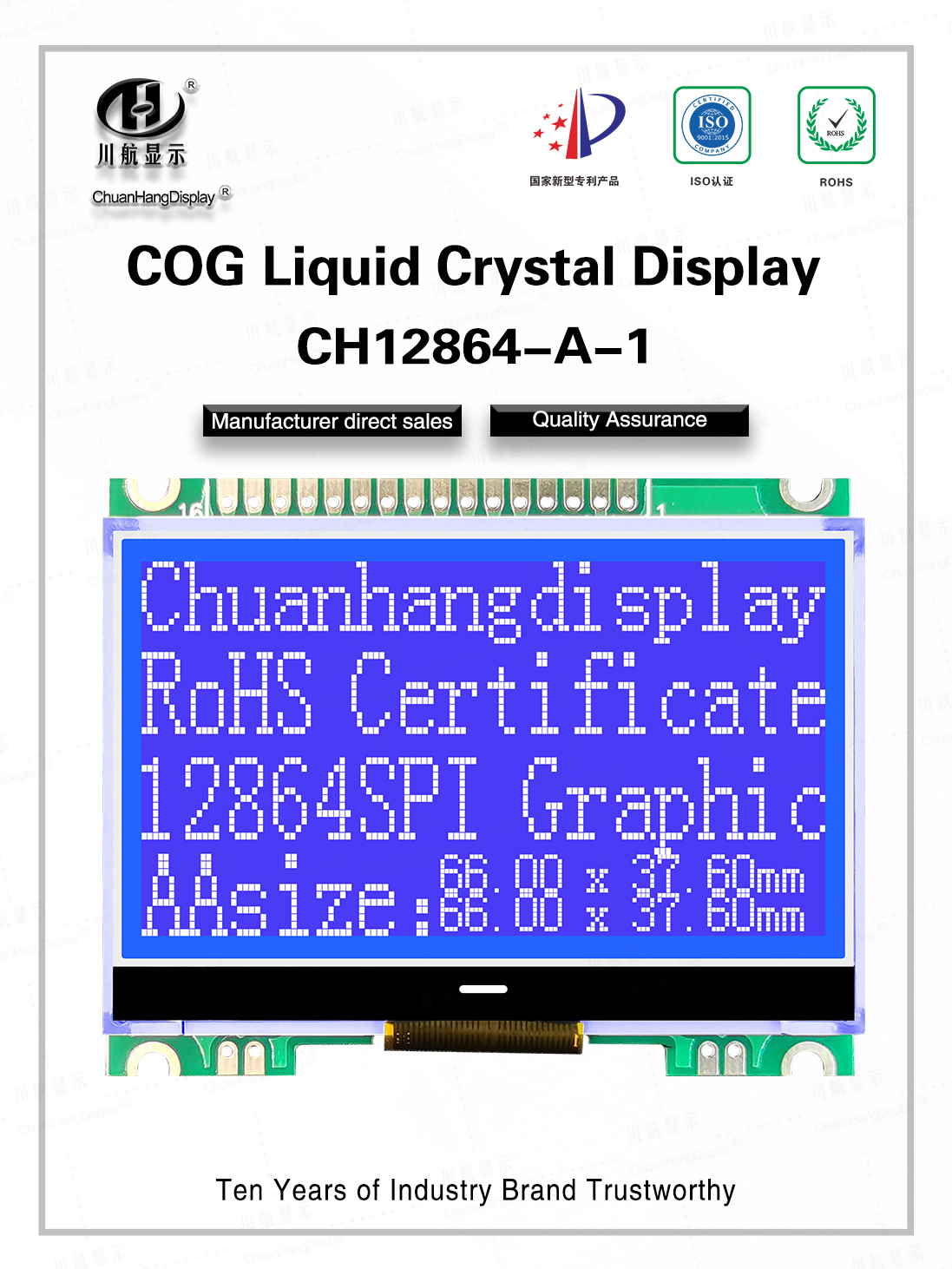

Q5: What does "COB" vs "COG" mean in module construction?

A5: COB stands for "Chip On Board," where the controller chip is mounted on the PCB and covered with a black epoxy blob; this is very robust and common for character modules. COG stands for "Chip On Glass," where the controller is mounted directly on the glass edge; this makes the module much thinner and is useful for space-constrained designs.