In the world of industrial interface design, the requirement to display more than just simple text is growing. While character modules handle basic alphanumeric data efficiently, they fall short when a device needs to show trend graphs, company logos, multi-language fonts, or custom UI icons. This is where the graphic LCD becomes the critical component in the engineer's toolkit.

For decades, these displays have served as the primary interface for medical equipment, industrial controllers, and handheld measurement tools. They offer a balance between information density and power efficiency that full-color TFTs often cannot match.

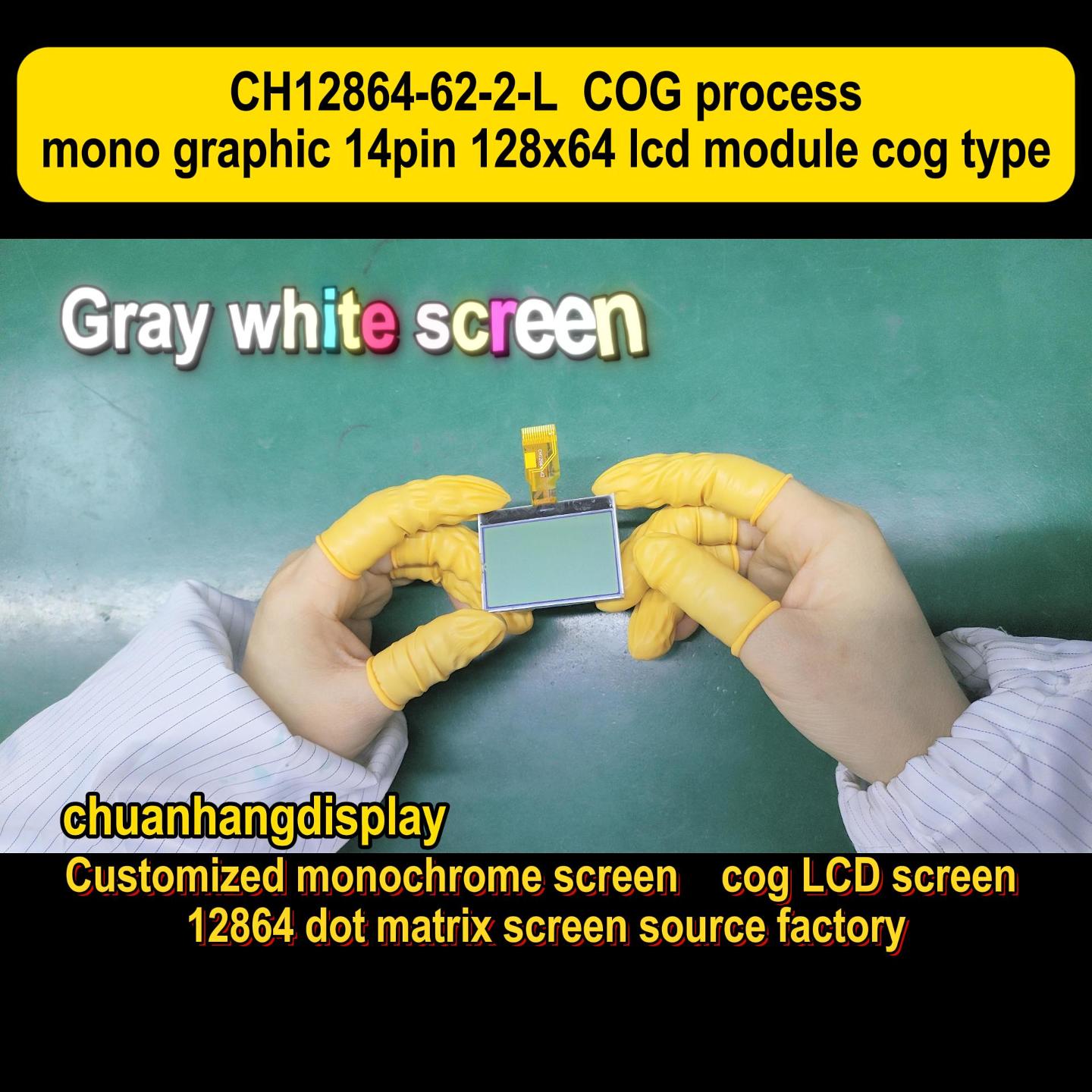

At Chuanhang Display, we see a consistent demand for these reliable modules. Engineers choose them because they provide complete control over every pixel on the screen. This flexibility allows for a user experience that is functional, clear, and robust enough to withstand harsh operating environments.

The core difference between a segment or character display and a graphic LCD lies in the addressing method. In a graphic module, the screen is a continuous matrix of pixels, typically arranged in rows and columns.

There are no predefined "character blocks." Instead, the host microcontroller sends data to turn specific dots on or off. This architecture means the software driver is responsible for defining what a "letter" looks like, or drawing a line from point A to point B.

This requires a frame buffer in the microcontroller's RAM or within the display controller itself. While this increases the software complexity slightly compared to character displays, the payoff is limitless flexibility. You can mix various font sizes, draw schematic diagrams, or implement a completely custom Graphical User Interface (GUI).

Selecting the right resolution is the first step in the design process. The industry has standardized several matrix sizes that cover the majority of use cases.

128x64 Dots: This is arguably the most common format in the industry. It provides enough width for roughly 20 characters and enough height for 8 lines of text, or a combination of text and icons. It is the standard for 3D printer controllers and network switches.

240x128 Dots: For applications requiring higher density, such as medical heart rate monitors or complex CNC machines, this resolution offers significantly more real estate. It allows for split-screen layouts where data and menus coexist.

240x64 Dots: This is a "widescreen" format often used in rack-mounted audio equipment or server appliances where vertical height is limited but horizontal space is available.

Chuanhang Display manufactures these standard sizes alongside smaller formats like 122x32, ensuring that mechanical integration into existing enclosures remains straightforward for product designers.

The readability of a graphic LCD is determined by the fluid technology and the polarizer films used during manufacturing.

STN (Super Twisted Nematic): This is the cost-effective standard. STN displays are typically yellow-green or blue. While reliable, they can suffer from color shifting at extreme viewing angles. They are best suited for devices that will be viewed directly from the front.

FSTN (Film Compensated STN): This technology adds a retardation film to the glass stack. This film compensates for the color dispersion of the STN layer, resulting in a black-and-white image. The contrast is much higher, and the viewing angles are wider.

For premium industrial applications, we often recommend FSTN. The sharp contrast between the dark pixels and the light background makes the content legible even at a quick glance, which is vital for safety equipment and alarm panels.

Engineers must decide between positive and negative display modes based on the operating environment.

Positive Mode: Dark pixels on a light background. This is standard for office equipment and devices used in well-lit rooms. It works exceptionally well with reflective or transflective polarizers, making it readable even in direct sunlight without using the backlight.

Negative Mode: Light pixels on a dark background. This requires the backlight to be active to see the content. It provides a sleek, modern look often associated with high-tech instrumentation. However, it consumes more power since the backlight is mandatory for visibility.

Every graphic LCD module contains a controller driver IC (or a set of them). This chip is the brain of the display. It manages the refresh rate, the bias voltages for the liquid crystal, and the communication with the host MCU.

Classic controllers like the Toshiba T6963C set the standard for larger resolution displays (like 240x128). For smaller displays (like 128x64), controllers compatible with the KS0108 or the modern ST7920 are ubiquitous.

The choice of controller dictates the interface. The ST7920, for instance, is popular because it supports both parallel and serial modes and includes a built-in Chinese/English font ROM, which acts as a hybrid between graphic and character capabilities.

At Chuanhang Display, we ensure our modules use widely supported controllers. This guarantees that engineers can find existing open-source libraries and driver code, significantly shortening the software development lifecycle.

Connecting the display to the main circuit board involves choosing the right data bus.

Parallel (6800/8080): This is the traditional method. It uses 8 data lines plus control lines (Read, Write, Chip Select, Reset). It is fast and allows for rapid screen updates. However, it uses a large number of GPIO pins on the microcontroller.

SPI (Serial Peripheral Interface): Many modern Chip-On-Glass (COG) graphic modules utilize SPI. It typically requires only 3 to 5 wires. This saves board space and reduces connector costs. The trade-off is speed; updating a full graphic screen over serial can be slower, but for most industrial UIs, it is more than adequate.

I2C: This uses the fewest pins (SDA and SCL) but is generally the slowest option. It is ideal for small graphic displays where the content does not change rapidly.

Power consumption is a major concern for handheld devices. The graphic LCD itself consumes very little power (often in the micro-amp range), but the backlight is the primary energy consumer.

Modern modules use LED side-lighting or array-lighting. Side-lighting is thinner and uses fewer LEDs, making it energy efficient. Array-lighting places LEDs behind the entire glass area, providing very uniform brightness but consuming more current.

Driving the backlight with a PWM (Pulse Width Modulation) signal allows the user to adjust brightness. This is a standard feature in designs by Chuanhang Display, allowing the device to dim the screen to save battery or adjust for night-time viewing.

The physical build of the module impacts the durability and the profile of the final product.

COB (Chip On Board): The controller IC is mounted on the PCB and covered with a blob of epoxy. These modules are physically larger and heavier but are extremely robust. They are easy to mount using screws and are resistant to vibration. This is the preferred style for heavy machinery.

COG (Chip On Glass): The controller is mounted directly onto the edge of the LCD glass. This eliminates the PCB area required for the chip, making the module very thin and lightweight. COG displays are dominant in handheld devices, medical portables, and consumer electronics where space is at a premium.

Unlike consumer tablets that may shut down in the heat, industrial equipment must run 24/7 in varying climates.

A standard liquid crystal fluid might become sluggish and slow to respond at -10°C. At high temperatures (above 60°C), the background might darken (isotropic phase), making the screen unreadable.

Chuanhang Display offers Wide Temperature variants. These use specialized fluid mixtures that maintain viscosity and contrast from -20°C up to +70°C. For automotive or military specs, we can push this range even further. Specifying the correct temperature range is critical to preventing field failures in outdoor kiosks or unconditioned factory floors.

Modern users expect touch interaction, even on monochrome screens. A graphic LCD can be equipped with a touch panel overlay.

Resistive Touch: This is the most common for this technology. It works with gloves and styluses, making it perfect for factory environments where operators wear protective gear. It is cost-effective and integrates easily with the display bezel.

Capacitive Touch: While less common on monochrome displays, it is possible. It offers the "smartphone feel" but requires a more complex controller and generally does not work with heavy gloves.

While standard modules fit many applications, optimal product design often requires customization.

The Flexible Printed Circuit (FPC) is a common customization point. The length, shape, and pinout of the FPC can be adjusted to match the connector position on the customer's mainboard. This eliminates the need for awkward cable folding or extension jumpers.

Chuanhang Display also provides custom glass sizing. If your device housing has a unique shape, the active area and viewing area of the glass can be manufactured to specific dimensions. Custom icons can also be permanently etched into the glass for fixed status indicators that are always visible.

The transition from simple text to graphical interfaces is a defining trend in industrial electronics. A well-chosen graphic LCD elevates the perceived quality of a device, improves operator efficiency, and provides flexibility for future software updates.

By understanding the nuances of resolution, fluid technology, and interface protocols, engineers can select a display that ensures longevity and reliability. Chuanhang Display remains committed to supporting this technology, providing high-quality, stable modules that empower the next generation of industrial design.

Q1: What is the difference between a graphic LCD and a TFT display?

A1: A graphic LCD is typically monochrome (black/white or blue/white) and uses passive matrix technology. It is low power, high contrast, and easy to drive with simple microcontrollers. A TFT (Thin Film Transistor) display is full color, uses active matrix technology, requires a powerful processor with a high-speed interface, and consumes significantly more power.

Q2: Can I use a graphic module in direct sunlight?

A2: Yes, but you must select the correct mode. A "Transflective" Positive mode display is the best choice. It uses a semi-transparent mirror that reflects sunlight to illuminate the screen. The brighter the sun, the easier it is to read. Transmissive displays (like those used in laptops) will wash out and become unreadable outdoors.

Q3: How do I control the contrast of the screen?

A3: Contrast is controlled by the voltage applied to the V0 or VOP pin. In many designs, this is handled by a physical potentiometer (variable resistor) connected to the pin. However, many modern controllers allow for software-defined contrast, where the MCU sends a command to an internal charge pump to adjust the voltage, eliminating the need for the external potentiometer.

Q4: Why does the display look blue when I view it from the side?

A4: This is likely an STN (Super Twisted Nematic) characteristic. STN technology has a specific "Cone of Vision." Outside of this optimal angle, the colors interfere, often creating a blue or purple hue. If wide viewing angles are required, upgrading to FSTN (Film Compensated) technology is recommended as it neutralizes these color shifts.

Q5: What is the typical lifespan of these displays?

A5: The liquid crystal glass itself is extremely durable and can last for decades without degradation if kept within temperature specs. The limiting factor is usually the LED backlight, which typically has a half-life (time to reach 50% brightness) of 50,000 to 70,000 hours. Chuanhang Display uses high-quality LEDs to ensure maximum longevity for industrial deployments.