When designing electronics, off-the-shelf displays often fall short. They might not fit your form factor, lack the required visibility, or fail to reflect your brand's identity. This is where the power of a custom segment display becomes undeniable. Unlike standard units, a custom segment display is engineered from the ground up to meet specific mechanical, electrical, and optical requirements. For engineers and product managers, opting for a customized display solution is a strategic decision that impacts usability, durability, and market differentiation. This article cuts through the noise, offering tangible insights into how these displays work, where to use them, and how to source them effectively.

A segment display, at its core, is an electronic device that presents alphanumeric characters or simple symbols using individually controllable segments. Think of classic digital clocks or calculator screens. A custom segment display takes this fundamental concept and tailors every aspect.

This means the segment layout, the number of digits, the color of the LEDs or LCD elements, the viewing angle, the operating temperature range, and the physical dimensions are all specified by the customer. The result is a component that feels inherently built-in, not an afterthought. The process moves from a standard catalog part to a co-engineered custom LCD or LED assembly.

Why choose a custom segment display over a cheaper, readily available standard module? The differences are substantial.

The use of custom segment displays spans numerous industries. Knowing where they excel helps in selection.

Primary Applications:

How to Select Your Custom Display:

Finding a capable supplier is the most crucial step. You need a partner, not just a vendor. Look for manufacturers with proven expertise in custom LCD and LED technologies, from design support to full-scale production.

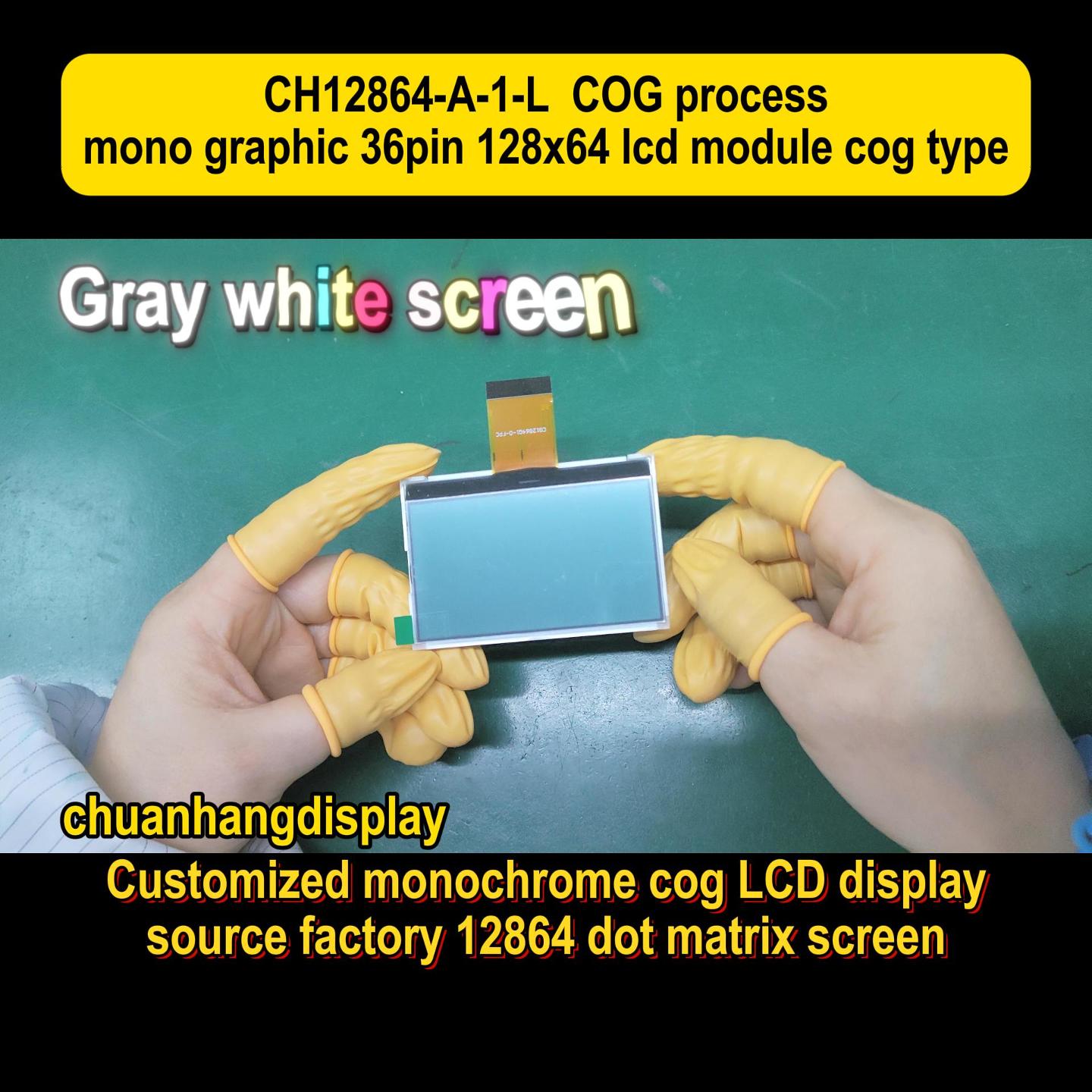

A company like Chuanhang Display exemplifies this partner approach. With deep experience in the international LCD field, they offer end-to-end services. They can assist with initial glass mask design for truly custom segment displays, prototype development, and rigorous testing phases. Their manufacturing capabilities ensure that your custom segment display is not only designed well but also produced with consistent quality for volume orders.

When evaluating suppliers, ask about their design for manufacturability (DFM) input, their minimum order quantities (MOQs) for customized solutions, and their lead times from prototype to production.

The price of a custom segment display is not arbitrary. Several factors influence the final cost.

Investing in a custom segment display is often justified by reduced assembly costs, superior product performance, and a stronger market position.

Creating a custom segment display is a precise engineering endeavor. For an LCD-based unit, the process is highly specialized.

It begins with the customer's specifications. The manufacturer, like Chuanhang Display, creates a detailed glass mask design. This mask is used to pattern the transparent ITO (Indium Tin Oxide) electrodes onto the glass substrates in the exact shape of your required segments. Two pieces of this patterned glass are assembled with a liquid crystal material sealed between them.

Polarizers are laminated on the outer surfaces, and a custom backlight unit (LED or EL) is designed to provide even illumination. The drive electronics, often a simple controller or custom IC, are developed to match your interface. Throughout, rigorous testing for electrical function, optical performance, and environmental resilience ensures the final custom segment display meets all specifications.

This control over the core technology is what allows for the high degree of customization and performance optimization.

Choosing a custom segment display is an investment in your product's integrity and user experience. While it involves more initial planning and potentially higher upfront costs than selecting a standard part, the long-term benefits in product differentiation, reliability, and perfect integration are compelling. By carefully defining your needs and partnering with an experienced manufacturer such as Chuanhang Display, you can transform a standard component into a defining feature of your device.

Q1: What is the typical lead time for developing a custom segment display prototype?

A1: The lead time for a custom segment display prototype can vary based on complexity. For a standard custom LCD segment design, it typically ranges from 4 to 8 weeks. This includes time for design finalization, glass mask fabrication, and initial sample assembly. Suppliers like Chuanhang Display can often provide more accurate timelines after reviewing detailed specifications.

Q2: Are custom segment displays only based on LCD technology?

A2: No, while LCD is very common due to its low power consumption and flexibility, custom segment displays can also be built using LED, VFD (Vacuum Fluorescent), or even OLED technology. The choice depends on factors like required brightness, viewing angle, color, power budget, and operating environment.

Q3: How durable are custom segment displays, especially for outdoor use?

A3: Durability is a key advantage of customized displays. They can be engineered for rugged environments. For outdoor use, features like wide-temperature liquid crystals (from -30°C to +80°C and beyond), UV-resistant polarizers, enhanced anti-glare treatments, and optically bonded interfaces can be specified to ensure long-term reliability and readability in direct sunlight.

Q4: What information do I need to provide to get an accurate quote for a custom display?

A4: To receive a precise quote, you should provide: 1) Detailed mechanical drawings with dimensions, 2) The desired segment layout and content (a visual mock-up is ideal), 3) Key performance requirements (operating voltage, temperature range, brightness), 4) Your estimated annual volume, and 5) Any special requirements like touch functionality or specific optical filters.

Q5: Can I integrate a touch interface into a custom segment display?

A5: Yes, absolutely. Touch functionality, such as capacitive touch buttons or sliders positioned around or even over the custom segment display area, is a common customization. This allows for creating sleek, integrated control panels without separate physical buttons, streamlining the user interface and product design.