If you're designing a device that needs to show clear, reliable numbers or simple characters, you've likely considered a 7 segment LCD display. These workhorses of the digital readout world are everywhere—from kitchen scales and thermostats to medical devices and industrial panels.

But there's more to them than meets the eye. Choosing the right one involves understanding their core technology, trade-offs, and when a standard part isn't enough. This article breaks down seven key aspects you need to know.

A 7 segment LCD display is a type of liquid crystal display that forms characters using seven individual bars (segments). An optional eighth segment for a decimal point is common. Each segment is a separate electrode. When voltage is applied to a segment, the liquid crystals align to make that area appear dark against a light background (positive display) or light against a dark background (negative display).

Their primary strength is unmatched simplicity and legibility for numeric data. They consume extremely low power, making them ideal for battery-operated devices. This fundamental efficiency is why the 7 segment LCD display remains a top choice over decades.

Why pick an LCD over other 7-segment options like LED or VFD? Each has its place.

LED 7-Segment Displays are very bright and self-illuminating, perfect for dark environments. However, they consume more current and can be harder to read in direct sunlight due to washout.

VFD (Vacuum Fluorescent) Displays offer high brightness and a wide viewing angle with a distinctive blue-green glow. They are robust but require relatively high voltage and power, and are less common now.

The 7 segment LCD display shines in power-critical applications and high-ambient-light conditions. It relies on reflected or backlight light, so it's perfectly readable under sunlight. For portable, solar-powered, or always-on devices, its ultra-low power consumption is the decisive factor.

You interact with these displays daily. Common applications include:

How to select one: Start with the basics. Determine the number of digits you need. Check the required digit height for viewing distance. Decide on a positive or negative mode based on your enclosure lighting. Crucially, define the operating temperature range and whether a backlight is needed for low-light conditions.

Sometimes, a catalog 7 segment LCD display doesn't fit. Perhaps you need a specific digit height, an unusual number of digits in a compact space, or a special icon next to the digits. This is where custom 7 segment LCD options come in.

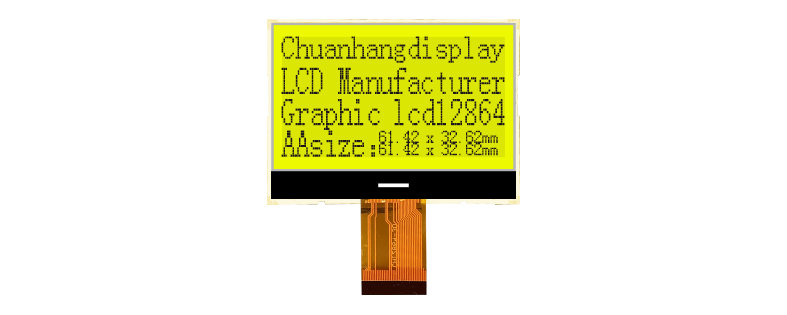

Working with a specialist like Chuanhang Display allows you to tailor everything. You can specify the exact segment layout, the connection pinout, the glass shape and size, and the type of liquid crystal for extended temperature performance. A custom segment LCD ensures perfect mechanical integration and can include brand-specific symbols.

Understanding drive modes is crucial for your circuit design. A 7 segment LCD display can be driven in two main ways:

Static Drive assigns one driver pin per segment. It offers the simplest control and best visual quality (no flicker) but becomes impractical for more than a few digits due to high pin count.

Multiplex (Multiplexed) Drive is the standard for multi-digit displays. Segments from different digits are connected in parallel, and digits are activated one at a time rapidly. This saves a tremendous number of driver pins. Effective LCD custom design optimizes the multiplexing scheme (e.g., 1/2, 1/3, 1/4 duty) to balance complexity, cost, and contrast.

The price of a 7 segment LCD display varies widely.

A standard, off-the-shelf module with common digits and pinout is very cost-effective at volume. The price increases with digit count, larger size, and special features like a wide temperature range or integrated backlight.

For a custom 7 segment LCD, the main cost driver is the Non-Recurring Engineering (NRE) fee. This covers the creation of the unique glass photomask—the template that defines your segments. At Chuanhang Display, engineers work to minimize this initial cost through smart design. Once the mask is made, per-unit costs become competitive, especially for production runs in the thousands.

The quality of a 7 segment LCD display hinges on manufacturing precision. It starts with patterning the transparent ITO (Indium Tin Oxide) electrodes on glass substrates using the photomask. The alignment of the top and bottom glass is critical.

The liquid crystal material is chosen based on the operating temperature range. The seal must be perfect to prevent contamination. Polarizers are laminated on the outside; their quality defines the contrast and viewing angle. For a custom LCD, the process includes rigorous testing for electrical function, visual uniformity, and environmental stability.

This controlled process by experienced manufacturers ensures the display will perform reliably for years, even in harsh conditions.

Not all display suppliers are equal. For standard parts, look for a broad catalog and reliable stock. For custom 7 segment LCD projects, seek a partner with in-house engineering support.

A manufacturer like Chuanhang Display provides value from concept to mass production. They assist with optical simulation, driver IC recommendations, and design-for-manufacturability advice. Their expertise in the international LCD field ensures your custom segment LCD is not only designed right but also built to last, with consistent quality across your entire production order.

The humble 7 segment LCD display is a deceptively simple component that remains vital in modern electronics. Its ultra-low power draw and sunlight readability are unmatched. By understanding its technology, applications, and the possibilities of customization, you can make the optimal choice for your product's performance, cost, and design integrity.

Q1: How do I connect and control a 7 segment LCD display with my microcontroller?

A1: You typically need an LCD driver chip or a microcontroller with built-in LCD driver peripherals. These drivers generate the specific AC waveforms required to control the segments without damaging the liquid crystal. You send data via SPI or I2C to the driver, which handles the multiplexing timing. Manufacturers like Chuanhang Display can recommend suitable driver ICs.

Q2: What is the typical operating temperature range for a standard 7 segment LCD display?

A2: A standard commercial-grade 7 segment LCD display usually operates from about -10°C to +60°C. For applications in automotive, industrial, or outdoor settings, extended-temperature versions are available. Through customization, suppliers can provide displays rated from -30°C to +80°C or even wider ranges using specialized liquid crystal mixtures.

Q3: Can I get a 7 segment LCD display with an integrated backlight?

A3: Yes, absolutely. LED backlights (typically side-lit or bottom-lit) are commonly added. For a custom 7 segment LCD, you can specify the backlight color (white, blue, green, red) and brightness level to meet your product's aesthetic and visibility requirements. Note that a backlight will increase power consumption.

Q4: What does "duty cycle" or "bias" mean in the context of these displays?

A4: These terms relate to the multiplex drive scheme. The "duty" (e.g., 1/3, 1/4) refers to how many common connections (backplanes) the display has. The "bias" (e.g., 1/2, 1/3) is the voltage ratio used to select segments. Together, they define the driving waveform. Your driver IC must be configured to match the display's specified duty and bias to achieve good contrast and avoid ghosting.

Q5: How long does it take to develop a prototype for a custom 7 segment LCD design?

A5: The timeline for a custom segment LCD prototype depends on complexity. After design approval, creating the first glass samples typically takes 4 to 6 weeks. This includes photomask fabrication and initial assembly. Working with an efficient manufacturer like Chuanhang Display can help streamline this process. Always factor in time for testing and potential minor revisions.