In today's fast-paced electronics industry, the demand for high-quality display solutions is skyrocketing. Whether it's for smartphones, medical devices, automotive displays, or industrial equipment, the backbone of these innovations often lies in the capabilities of an lcd module factory. But what exactly goes into such a facility, and why is choosing the right one crucial for your business success? This article delves deep into the world of LCD module factories, covering everything from their core functions to future trends. We'll explore how a well-equipped lcd module factory operates, the key aspects that set top performers apart, and why brands like Chuanhang Display have become benchmarks in this field. By the end, you'll have a clear understanding of how to evaluate an lcd module factory for your specific needs, ensuring you partner with a provider that delivers reliability and innovation.

An lcd module factory is a specialized manufacturing facility dedicated to producing LCD (Liquid Crystal Display) modules, which are essential components in a wide range of electronic devices. These factories integrate various processes, from designing and assembling LCD panels to incorporating backlighting, drivers, and touch interfaces. Unlike generic electronics plants, an lcd module factory focuses on precision and customization, catering to industries that require high-resolution displays with specific performance criteria. For instance, in consumer electronics, an lcd module factory might produce modules for smartphones, while in healthcare, they could create displays for medical monitors. The core of any reputable lcd module factory lies in its ability to handle complex supply chains, employ advanced technologies, and maintain stringent quality standards. This makes the lcd module factory a pivotal player in the global tech ecosystem, driving innovations that impact everyday life. By understanding the fundamental role of an lcd module factory, businesses can better appreciate why selecting the right partner—such as Chuanhang Display—can lead to enhanced product performance and market competitiveness.

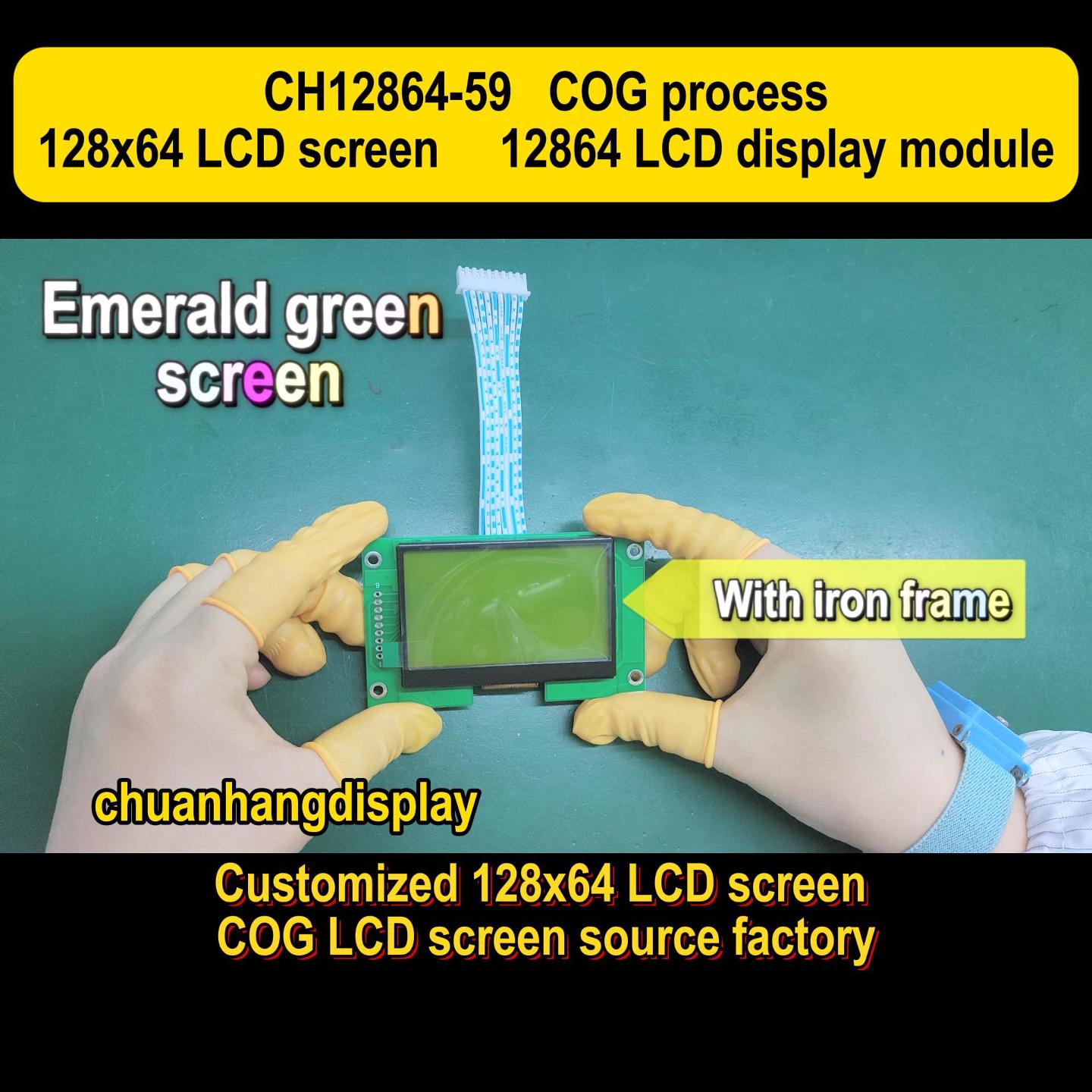

A modern lcd module factory is built around several critical components that ensure efficient production and high output quality. First, the cleanroom environment is essential, as even microscopic dust particles can defects in LCD modules. This controlled space, often with ISO-certified standards, minimizes contamination during assembly. Second, an lcd module factory relies on advanced machinery for processes like COG (Chip-on-Glass) and TAB (Tape Automated Bonding), which attach integrated circuits directly to the glass substrates. These technologies enable the factory to produce slim, energy-efficient modules with high reliability. Third, testing equipment is a cornerstone of any lcd module factory, including automated optical inspection (AOI) systems and environmental chambers that simulate extreme conditions to validate durability. Additionally, a robust lcd module factory incorporates supply chain management for sourcing raw materials like polarizers, glass, and LEDs, ensuring consistency across batches. For example, at Chuanhang Display, their lcd module factory emphasizes modular infrastructure that allows for scalable production, from small custom orders to large-scale runs. This holistic approach in an lcd module factory not only boosts efficiency but also reduces lead times, making it a go-to choice for clients seeking dependable display solutions.

The productiontechnological proces in an lcd module factory is a multi-stage endeavor that transforms raw materials into functional display modules. It typically begins with design and prototyping, where engineers use CAD software to create schematics based on client specifications. Once approved, the lcd module factory moves to panel fabrication, involving the deposition of thin-film transistors on glass substrates to form the LCD matrix. This is followed by cell assembly, where liquid crystal material is injected between glass layers and sealed. Next, the backlight unit is integrated—a crucial step in an lcd module factory, as it determines brightness and uniformity. Drivers and controllers are then bonded to the panel using automated techniques like SMT (Surface Mount Technology). Throughout this process, an lcd module factory employs rigorous inline inspections to catch defects early. For instance, at Chuanhang Display's lcd module factory, real-time monitoring systems track each module's performance metrics, ensuring that only units meeting strict criteria proceed to packaging. This detailed approach in an lcd module factory highlights why precision and automation are vital for producing displays that meet industry standards, such as those for automotive or military applications where reliability is non-negotiable.

Quality assurance is the heartbeat of any successful lcd module factory, as even minor flaws can lead to device failures. A comprehensive lcd module factory implements multiple layers of testing, starting with material inspection to verify the quality of incoming components like glass and LEDs. During production, automated systems in the lcd module factory perform electrical tests to check for shorts, open circuits, and signal integrity. Environmental testing is another critical phase, where modules undergo thermal cycling, humidity exposure, and vibration tests to ensure they withstand real-world conditions. Moreover, an lcd module factory often adheres to international standards such as ISO 9001 for quality management and ISO 14001 for environmental safety. For example, Chuanhang Display's lcd module factory boasts a defect rate of less than 0.1% due to their multi-stage validation process, which includes burn-in tests to assess long-term performance. This emphasis on quality in an lcd module factory not only safeguards brand reputation but also reduces warranty claims and recalls, making it a smart investment for businesses prioritizing durability and customer satisfaction.

Choosing the right lcd module factory can make or break your product's success, so it's essential to evaluate several factors. First, assess the factory's technological capabilities—does the lcd module factory support custom designs, and what is their lead time for prototypes? A facility like Chuanhang Display's lcd module factory, for instance, offers rapid prototyping with turnkey solutions, which can accelerate time-to-market. Second, consider the lcd module factory's experience in your industry; for medical or automotive displays, look for certifications like ISO 13485 or IATF 16949. Third, scalability is key—an lcd module factory should handle volume fluctuations without compromising quality. Fourth, evaluate the supply chain resilience; a robust lcd module factory maintains multiple sourcing options to avoid disruptions. Lastly, cost-effectiveness matters, but don't sacrifice quality for lower prices. Visiting the lcd module factory in person or reviewing case studies can provide insights into their operational excellence. By focusing on these aspects, you can partner with an lcd module factory that aligns with your business goals, much like how Chuanhang Display has built trust through transparent processes and consistent delivery.

The landscape of an lcd module factory is evolving rapidly, driven by trends like IoT, AI, and sustainability. Modern lcd module factories are integrating smart manufacturing techniques, such as Industry 4.0, which uses IoT sensors to optimize production lines in real-time. This allows an lcd module factory to predict maintenance needs and reduce downtime. Additionally, there's a growing emphasis on eco-friendly practices; for example, many lcd module factories are adopting lead-free materials and energy-efficient processes to minimize environmental impact. Another trend is the shift toward flexible and OLED displays, prompting an lcd module factory to invest in R&D for next-gen technologies. Brands like Chuanhang Display are at the forefront, with their lcd module factory exploring innovations in touch integration and low-power displays for wearable devices. As demand for high-resolution, durable screens grows, the lcd module factory of the future will likely focus on customization and agility, ensuring they can meet diverse market needs while maintaining high standards.

Chuanhang Display exemplifies what a top-tier lcd module factory should be, with a track record of delivering high-performance displays across various sectors. Their lcd module factory is equipped with state-of-the-art automation, allowing them to produce over 10 million modules annually with consistent quality. One standout project involved developing custom LCD modules for automotive dashboards, where the lcd module factory implemented rigorous testing for temperature resilience and sunlight readability. By leveraging advanced COF (Chip-on-Film) technology, Chuanhang Display's lcd module factory achieved thinner bezels and better energy efficiency, meeting client specifications precisely. Moreover, their lcd module factory emphasizes customer collaboration, offering design support from concept to mass production. This case study underscores how a dedicated lcd module factory like Chuanhang Display can drive innovation while ensuring reliability, making them a preferred partner for businesses worldwide.

In summary, an lcd module factory is more than just a production site—it's a hub of technology, quality, and innovation that powers modern electronics. From understanding its core components to evaluating selection criteria, this article has covered the essential aspects that define a reliable lcd module factory. As industries continue to demand smarter and more efficient displays, partnering with a proven lcd module factory like Chuanhang Display can provide the edge needed to succeed. By prioritizing factors such as quality control, scalability, and future-ready trends, you can ensure that your investment in an lcd module factory yields long-term benefits. Remember, the right lcd module factory doesn't just manufacture displays; it enables your products to shine in a competitive market.

Q1: What is the typical lead time for an order from an LCD module factory?

A1: The lead time in an lcd module factory varies based on order size and customization, but it generally ranges from 4 to 8 weeks. For standard modules, a reputable lcd module factory like Chuanhang Display might offer shorter timelines, while complex designs could take longer due to additional testing and prototyping phases.

Q2: How does an LCD module factory ensure the durability of its products?

A2: An lcd module factory employs rigorous testing protocols, including environmental stress tests, vibration analysis, and burn-in periods, to validate durability. For instance, at Chuanhang Display's lcd module factory, modules undergo accelerated life testing to simulate years of use, ensuring they meet industry standards for reliability.

Q3: Can an LCD module factory handle small-batch or custom orders?

A3: Yes, many modern lcd module factories, including Chuanhang Display, specialize in custom and small-batch production. They offer flexible solutions tailored to specific client needs, supported by agile manufacturing processes that allow for efficient prototyping and low-volume runs without compromising quality.

Q4: What certifications should I look for in an LCD module factory?

A4: When selecting an lcd module factory, key certifications include ISO 9001 for quality management, ISO 14001 for environmental management, and industry-specific ones like ISO 13485 for medical devices or IATF 16949 for automotive. These indicate that the lcd module factory adheres to high standards of safety and consistency.

Q5: How does an LCD module factory manage supply chain disruptions?

A5: A robust lcd module factory mitigates supply chain risks by diversifying suppliers, maintaining inventory buffers, and using real-time tracking systems. For example, Chuanhang Display's lcd module factory has established partnerships with multiple component providers, ensuring uninterrupted production even during global shortages.