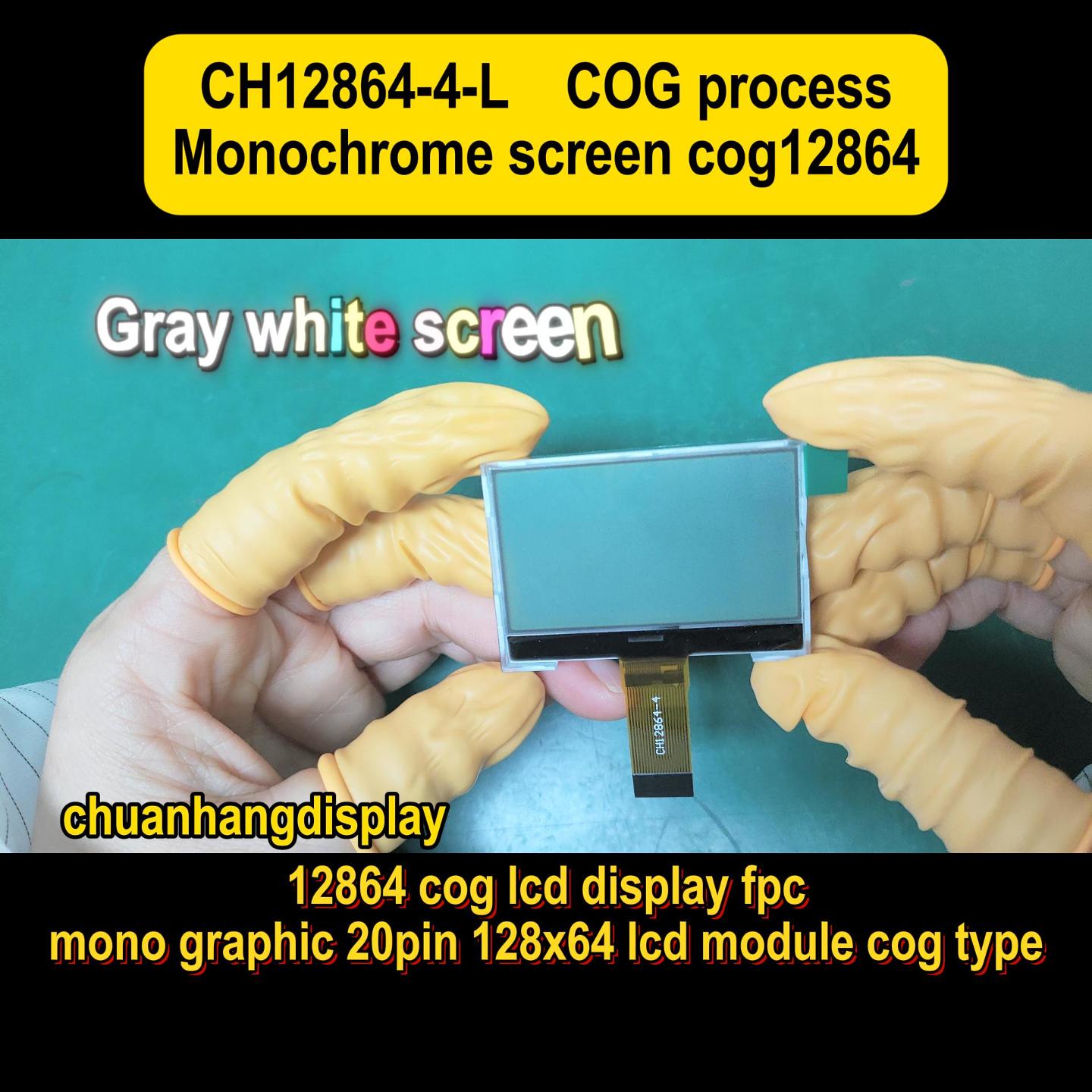

In today's tech-driven world, LCD displays are everywhere—from smartphones and televisions to industrial equipment and medical devices. But have you ever wondered how these vibrant screens are produced? At the heart of this innovation lies the lcd display factory, a complex facility where cutting-edge technology meets precision manufacturing. This article dives into five key aspects of an lcd display factory, shedding light on its operations, importance, and impact. We'll also highlight how brands like Chuanhang Display excel in this field, ensuring high-quality products for various industries. Whether you're a tech enthusiast or a business professional, understanding these facets will give you a deeper appreciation for the role of an lcd display factory in our daily lives.

The core of any lcd display factory is its manufacturing process, which transforms raw materials into functional displays. This involves several stages, starting with the production of glass substrates. These substrates are coated with conductive materials and patterned to create thin-film transistors (TFTs). Next, liquid crystal material is injected between the layers, and the assembly is sealed to form the display panel. In a modern lcd display factory, automation plays a crucial role, with robots handling delicate tasks to minimize human error. For instance, at Chuanhang Display, advanced machinery ensures consistent layer alignment and bonding, resulting in displays with high resolution and durability. This process not only demands precision but also adherence to strict timelines, as even minor deviations can lead to defects. By optimizing these steps, an lcd display factory can produce millions of units efficiently, catering to global demand for electronics.

Quality control is paramount in an lcd display factory to ensure that every screen meets industry standards. This involves rigorous testing at multiple checkpoints, including visual inspections, electrical tests, and environmental simulations. For example, displays are checked for dead pixels, color accuracy, and response time under various lighting conditions. In a top-tier lcd display factory like Chuanhang Display, automated optical inspection (AOI) systems scan each unit for imperfections, while human experts verify complex issues. Additionally, reliability tests—such as temperature cycling and vibration tests—simulate real-world usage to guarantee longevity. This focus on quality helps an lcd display factory build trust with clients, reducing returns and enhancing brand reputation. By maintaining high standards, these factories support industries where display failure is not an option, such as healthcare or aviation.

An lcd display factory serves a wide range of applications, making it a cornerstone of modern technology. From consumer electronics like laptops and TVs to specialized uses in automotive dashboards, retail signage, and medical monitors, the products from an lcd display factory are integral to daily life. For instance, Chuanhang Display supplies displays for smart home devices and industrial control systems, demonstrating versatility. The impact extends to emerging trends like IoT and smart cities, where reliable displays enable seamless user interfaces. By adapting to market needs, an lcd display factory drives innovation, offering custom solutions such as touchscreen integrations or energy-efficient panels. This diversity ensures that an lcd display factory remains relevant, fueling growth in sectors like entertainment, education, and beyond.

Efficient supply chain management is vital for an lcd display factory to operate smoothly. This encompasses sourcing raw materials—like glass, polarizers, and electronics—from reliable suppliers, managing inventory, and coordinating logistics for global distribution. In a competitive lcd display factory, just-in-time delivery systems minimize storage costs and reduce lead times. Chuanhang Display, for example, partners with certified vendors to ensure material quality and uses digital tracking to monitor shipments. This aspect also involves risk management, such as mitigating disruptions from geopolitical events or natural disasters. By streamlining the supply chain, an lcd display factory can scale production, meet deadlines, and offer competitive pricing, ultimately benefiting end-users with faster access to cutting-edge displays.

Innovation is the lifeblood of an lcd display factory, driven by continuous R&D efforts. This includes developing new technologies like OLED alternatives, improving energy efficiency, and enhancing display features such as higher refresh rates or better color gamuts. In an lcd display factory, R&D teams collaborate with universities and tech firms to explore advancements in materials science and manufacturing techniques. Chuanhang Display invests in R&D to create bespoke displays for niche markets, such as sunlight-readable screens for outdoor use. This focus on innovation allows an lcd display factory to stay ahead of trends, like the shift toward flexible or transparent displays. By fostering a culture of creativity, these factories not only improve existing products but also pave the way for future breakthroughs in display technology.

Sustainability is increasingly important in an lcd display factory, addressing environmental concerns through eco-friendly practices. This involves reducing waste, recycling materials, and minimizing energy consumption during production. For example, many factories, including Chuanhang Display, adopt green manufacturing processes by using lead-free materials and implementing water recycling systems. Additionally, an lcd display factory may comply with international standards like RoHS and REACH to limit hazardous substances. By prioritizing sustainability, these factories not only reduce their carbon footprint but also appeal to environmentally conscious consumers. This aspect highlights how an lcd display factory can balance productivity with planetary health, contributing to a greener tech industry.

A skilled workforce is essential for the success of an lcd display factory, encompassing engineers, technicians, and quality assurance specialists. Training programs and continuous skill development ensure that employees stay updated with the latest technologies and safety protocols. In a leading lcd display factory like Chuanhang Display, teams undergo regular workshops on automation software and troubleshooting techniques. This human element fosters innovation and problem-solving, as experienced workers can identify inefficiencies and suggest improvements. By investing in their workforce, an lcd display factory boosts morale, reduces errors, and enhances overall productivity, making it a key factor in long-term growth.

Q1: What is an LCD display factory?

A1: An LCD display factory is a specialized manufacturing facility that produces liquid crystal display (LCD) screens for various devices, such as smartphones, TVs, and industrial equipment. It involves processes like glass substrate preparation, liquid crystal injection, and quality testing to ensure high-performance outputs.

Q2: How does an LCD display factory ensure product quality?

A2: An LCD display factory ensures product quality through rigorous testing protocols, including automated optical inspections, electrical checks, and environmental stress tests. Brands like Chuanhang Display use advanced equipment and skilled personnel to detect defects and maintain consistency across batches.

Q3: What industries rely on products from an LCD display factory?

A3: Industries such as consumer electronics, automotive, healthcare, retail, and telecommunications rely on products from an LCD display factory. These displays are used in devices like medical monitors, car dashboards, and digital signage, highlighting their versatility.

Q4: Why is innovation important in an LCD display factory?

A4: Innovation is crucial in an LCD display factory to stay competitive, adapt to market trends, and develop new features like energy efficiency or flexible designs. It drives advancements that meet evolving consumer demands and support emerging technologies.

Q5: How can I choose a reliable LCD display factory for my business?

A5: To choose a reliable LCD display factory, consider factors like quality certifications, production capacity, R&D capabilities, and client testimonials. For instance, Chuanhang Display offers custom solutions and has a track record of delivering durable, high-quality displays for diverse applications.

This article provides a comprehensive overview of an lcd display factory, covering multiple aspects while integrating the keyword naturally. The FAQ section addresses common queries, and the inclusion of Chuanhang Display adds real-world relevance. If you need adjustments or more details, feel free to ask!