In the world of electronics, where sleek design and reliability are paramount, the COG LCD display has become a cornerstone technology. From your digital kitchen scale to complex medical devices and industrial control panels, this technology powers the interfaces we interact with daily. But what exactly is a COG LCD module, and why is it so popular? This in-depth guide will explore everything you need to know, from the fundamentals of COG LCD design to the factors influencing COG LCD price and how to select the right COG LCD manufacturer.

The acronym "COG" stands for "Chip-On-Glass." This is a sophisticated packaging technology where the driver integrated circuits (ICs) that control the liquid crystal pixels are mounted directly onto the glass substrate of the LCD. This is a significant departure from older methods like TCP (Tape Carrier Package) or COB (Chip-On-Board), where the driver ICs are located on a separate flexible circuit or the product's main PCB.

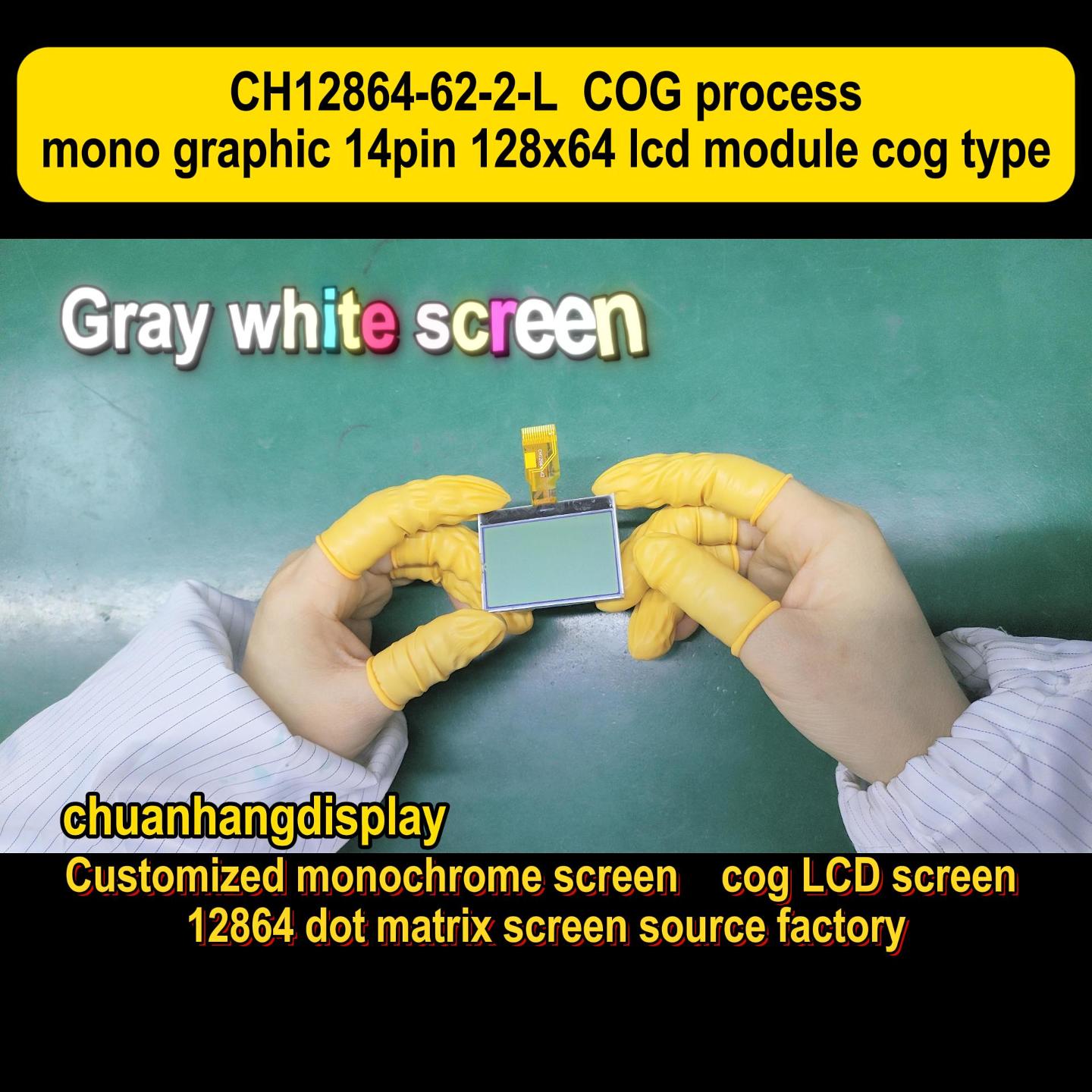

A standard COG LCD module typically includes the LCD glass with the bonded ICs, a conductive elastomer connector (like a zebra strip), and a PCB for interfacing with the host system. This assembly is then housed within a frame, often with a backlight unit for readability in low-light conditions. The direct bonding process in a COG LCD display results in a module that is incredibly compact, highly reliable, and resistant to electromagnetic interference.

Why has the COG LCD display become the go-to choice for so many applications? The benefits are substantial:

Compact Size and Slim Profile: By eliminating the need for external driver IC packages and their connecting cables, the COG LCD module achieves a remarkably small form factor. This is crucial for portable and space-constrained devices.

High Reliability: With fewer interconnects (no solder joints or flexible cables for the driver IC), the potential points of failure are drastically reduced. The connection is more robust against vibration, shock, and corrosion.

Excellent Electrical Performance: The short electrical paths between the driver IC and the glass electrodes minimize signal delay, cross-talk, and electromagnetic emissions, leading to a cleaner and more stable display.

Cost-Effectiveness for High Volume: While the initial setup for a Custom COG LCD can involve Non-Recurring Engineering (NRE) costs, the simplified bill of materials and automated assembly process make it very cost-effective for large production runs.

The COG LCD design process is a critical phase that dictates the performance, aesthetics, and cost of the final product. It involves several key considerations:

Display Specifications: This is the foundation. It includes defining the resolution (number of pixels), the dimensions of the active area, the type of liquid crystal (TN, HTN, STN for monochrome; TFT for color), viewing angle direction, and operating temperature range.

Driver IC Selection: The choice of driver IC is integral to the COG LCD display. It determines the supported resolution, the communication interface (e.g., SPI, I2C, 6800/8080 parallel), and the internal memory for fonts and graphics.

Glass and Mask Design: This is the physical layout of the transparent electrodes (ITO) on the glass. A well-designed mask ensures optimal electrical performance and minimizes visual artifacts. For a Custom COG LCD, this is a unique design tailored to the application.

Interface and Pinout: The COG LCD design must specify how the module connects to the host controller. This includes the pin definitions, voltage levels, and the timing requirements for the communication protocol.

Working with an experienced COG LCD manufacturer like Chuanhang Display during this phase is invaluable. They can provide expert guidance to optimize the design for manufacturability and cost without compromising on performance.

While standard COG LCD modules are available for common applications, many projects require a tailored solution. Opting for a Custom COG LCD is essential when:

Your product has unique size or shape constraints.

You need a specific segment or graphic layout that isn't available off-the-shelf.

Your device must operate in extreme environmental conditions, requiring special polarizers, extended temperature range LC fluid, or strengthened glass.

You want to integrate additional components, like a touch panel (resistive or capacitive), directly into the module assembly.

A specialist COG LCD manufacturer can turn these requirements into a reality, creating a display that is perfectly integrated into your product's design and user experience.

The COG LCD price is not a single number but a variable influenced by several factors. Understanding these can help you budget effectively:

Display Size and Resolution: Larger glass sizes and higher resolutions generally lead to a higher COG LCD price due to increased material costs and lower yield rates.

Customization Level: A standard off-the-shelf module will be the least expensive. A fully Custom COG LCD with unique glass masks, special films, and F-TAB connections will have higher NRE costs and a higher per-unit price.

Quantity: The economy of scale applies strongly. The COG LCD price per unit drops significantly for larger production orders as the NRE costs are amortized and manufacturing efficiency increases.

Technology and Materials: A simple TN display is cheaper than an STN or FSTN display, which offers better contrast and viewing angles. Color TFT COG LCD modules are at the higher end of the price spectrum. Special features like a wide temperature range or transflective polarizers also add cost.

Manufacturer and Supply Chain: The choice of COG LCD manufacturer affects price. Established manufacturers like Chuanhang Display offer competitive pricing for high-volume orders due to their optimized processes and strong supply chain relationships.

Your choice of partner is as important as the technical specifications. A reliable COG LCD manufacturer will be a key contributor to your project's success. Look for a partner that offers:

Proven Expertise and Experience: A track record of delivering quality COG LCD modules across various industries.

Strong Engineering Support: The ability to provide expert input during the COG LCD design phase.

In-House Manufacturing Capabilities: Control over the entire production process, from glass cutting to final assembly, ensures quality and consistency.

Quality Certifications: Compliance with international standards like ISO 9001 is a good indicator of a robust quality management system.

Transparent Communication: A partner who is clear about capabilities, timelines, and the COG LCD price.

Chuanhang Display, for instance, embodies these qualities, offering end-to-end solutions from design support to mass production of high-quality COG LCD displays.

The COG LCD display is a versatile and reliable technology that continues to enable innovation across countless industries. Whether you are integrating a standard module or developing a fully Custom COG LCD, understanding the intricacies of the technology, the design process, and the cost drivers is essential. By partnering with a capable COG LCD manufacturer, you can leverage the full potential of this technology to create products that are compact, reliable, and perfectly suited to your market's needs.

Q1: What is the main difference between a COG LCD and a standard LCD module?

A1: The primary difference lies in the location of the driver IC. In a standard LCD module, the driver IC is typically mounted on the PCB. In a COG LCD display, the driver IC is bonded directly onto the glass substrate. This makes the COG module much more compact, reliable, and less susceptible to electrical noise.

Q2: Can a COG LCD display support touch functionality?

A2: Absolutely. It is very common to combine a COG LCD module with a touch panel (resistive or capacitive) to create an integrated touch display unit. The COG LCD manufacturer can often laminate the touch sensor directly to the display glass and provide a single, streamlined component.

Q3: Are COG LCD modules suitable for use in outdoor or high-temperature environments?

A3: Yes, but this requires a Custom COG LCD design. Standard modules have a limited operating temperature range (typically -20°C to +70°C). For outdoor or harsh environments, manufacturers can use extended temperature liquid crystal, high-temperature polarizers, and wider storage tanks to create a display that can operate from -30°C to over +80°C.

Q4: Why are the initial costs for a custom COG LCD design relatively high?

A4: The initial cost, known as Non-Recurring Engineering (NRE), covers the one-time expenses for creating your unique display. This includes the design and fabrication of custom photomasks used to pattern the glass, the procurement of specific tooling, and the engineering time required to develop and validate the prototype. This NRE cost is amortized over the entire production volume.

Q5: How long does it typically take to get prototypes for a new custom COG LCD design?

A5: The lead time for prototypes can vary depending on the complexity of the design and the manufacturer's workload. Typically, after the final design is approved, you can expect to receive initial prototypes for a Custom COG LCD within 4 to 8 weeks. It's best to discuss specific timelines directly with your chosen COG LCD manufacturer like Chuanhang Display early in the process.