Walk into any electronics store, glance at your car's dashboard, or look at the medical device in a hospital, and you'll likely be looking at a TFT LCD screen. Thin-Film-Transistor Liquid Crystal Display technology has become the bedrock of modern visual interfaces, powering everything from the simplest digital watch to the most complex industrial control panel. But what exactly is a TFT LCD screen, and why has it become the dominant display technology across countless industries?

This article cuts through the technical jargon to provide a clear, comprehensive look at TFT LCDs. We'll explore how they work, their key advantages, and what to consider when sourcing them for your project, especially if you require a custom TFT LCD screen.

At its core, a TFT LCD screen is an active-matrix LCD, a significant evolution from older passive-matrix technologies. The "Thin-Film-Transistor" part is the key differentiator. Essentially, each individual pixel on the display is controlled by one to four tiny transistors. This active-matrix design allows for faster response times, sharper images, and better color reproduction compared to its predecessors.

Think of it like a city grid. In a passive-matrix display, it's as if you have a single traffic light controlling an entire intersection, leading to slow and muddled traffic flow. In an active-matrix TFT LCD screen, every single car (pixel) has its own dedicated traffic controller (transistor), resulting in precise, fast, and efficient control.

A TFT LCD screen is a complex sandwich of layers, each with a critical function:

Backlight Unit (BLU): Most TFT LCDs are not emissive by themselves. They require a light source from behind, typically composed of LEDs. This light shines through the subsequent layers.

Polarizing Filters: These are placed at the front and back of the screen. They only allow light waves oriented in a specific direction to pass through.

Glass Substrates and Liquid Crystal Layer: Sandwiched between the polarizers are two glass sheets. Between these sheets is a layer of liquid crystals. These crystals can twist and untwist in response to an electric current.

Color Filters: Each pixel is divided into three sub-pixels with red, green, and blue (RGB) color filters.

Thin-Film Transistors (TFTs): This is the star of the show. The TFT array is a grid of transistors built directly onto the glass. Each sub-pixel has its own transistor that acts as a precise switch, applying a specific voltage to the liquid crystal in that exact spot.

The process works like this: The backlight emits white light. As this light passes through the first polarizer, it becomes polarized. The liquid crystals, controlled by the TFTs, then twist this light to varying degrees. The second polarizer then blocks or allows this twisted light to pass through. By precisely controlling how much light passes through each red, green, and blue sub-pixel, the TFT LCD screen can create millions of distinct colors with high speed and accuracy.

Why has the TFT LCD screen remained so popular? Several key benefits contribute to its widespread adoption:

High Image Quality: Excellent color saturation, contrast, and sharpness are hallmarks of a good TFT display.

Cost-Effectiveness: Mass production over decades has made TFT technology highly economical, especially for standard sizes and specifications.

Reliability and Long Lifespan: With no moving parts and mature manufacturing processes, TFT LCDs are known for their durability and long operational life.

Scalability: The technology can be scaled to a wide range of sizes, from tiny 1-inch displays to large-format industrial monitors.

Maturity: As a mature technology, the supply chain is robust, and engineering support is widely available.

Not all TFT LCD screen products are the same. Several variations have been developed to enhance specific performance characteristics:

IPS (In-Plane Switching): IPS panels are renowned for their superior color consistency and wide viewing angles (often up to 178 degrees). This makes them ideal for applications where the screen may be viewed from off-angles, such as point-of-sale systems or shared instrumentation.

FFS (Fringe Field Switching): An evolution of IPS, FFS offers even better transmittance (brightness efficiency) and viewing angles. It's a high-performance variant often found in premium applications.

TN (Twisted Nematic): TN is one of the oldest and most cost-effective TFT technologies. Its main drawback is limited viewing angles and poorer color reproduction compared to IPS. However, it offers very fast response times, making it suitable for basic applications and some gaming monitors.

VA (Vertical Alignment): VA panels strike a balance between TN and IPS, offering better contrast and color than TN but with slower response times and less ideal viewing angles than IPS.

The versatility of the TFT LCD screen is evident in its cross-industry penetration:

Industrial Automation: HMIs (Human-Machine Interfaces) for factory control, PLC monitoring, and test equipment.

Medical Technology: Patient monitors, diagnostic imaging displays, and surgical equipment screens, where reliability and clarity are non-negotiable.

Automotive: Digital dashboards, center console infotainment systems, and rear-seat entertainment displays.

Consumer Electronics: Smart home interfaces, appliances, printers, and a vast array of other devices.

Marine and Aviation: Navigation systems and instrumentation for harsh environments.

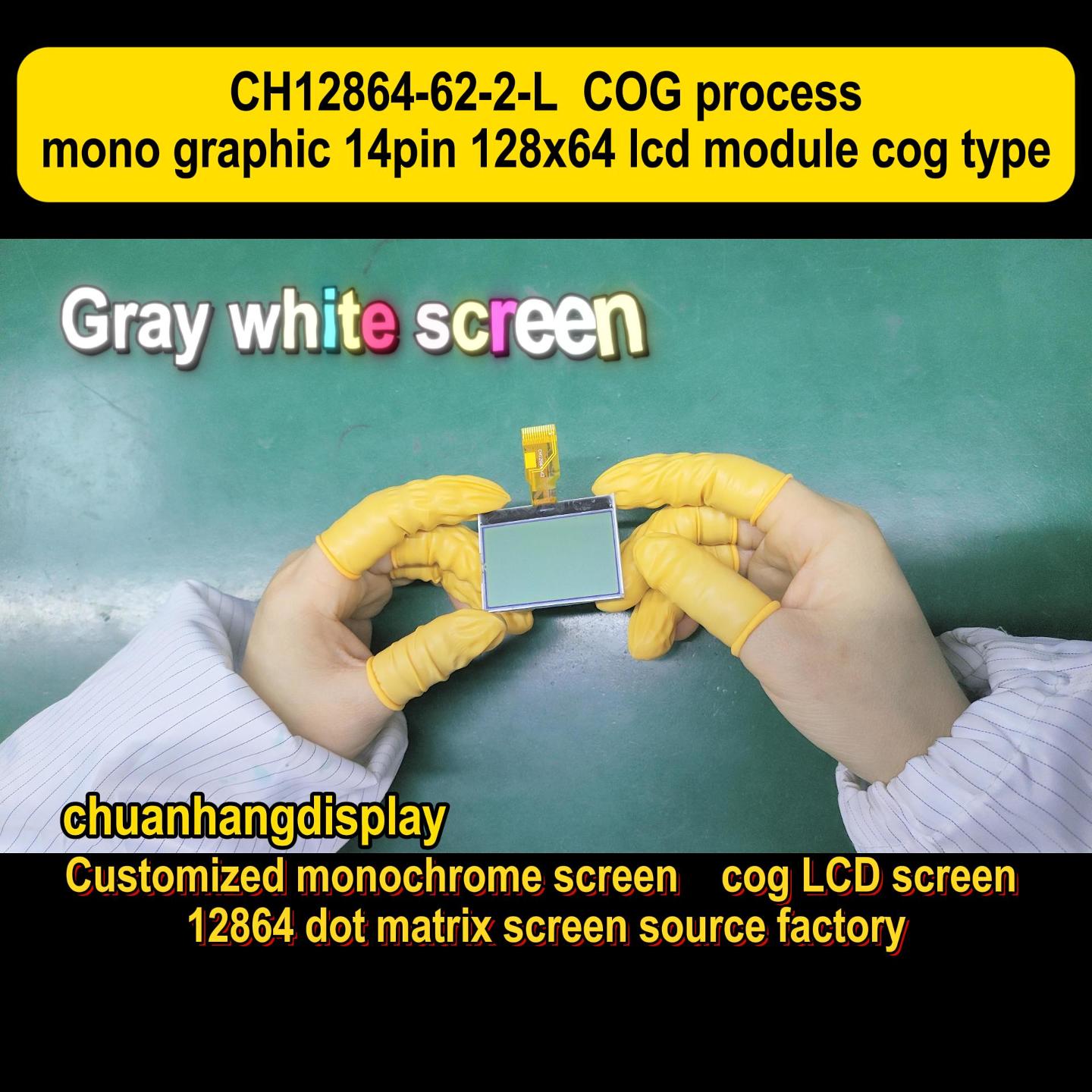

While standard modules are plentiful, many projects demand a tailored solution. This is where partnering with an experienced manufacturer like Chuanhang Display for a custom TFT LCD screen becomes critical. Customization can address several needs:

Form Factor and Size: Creating a display that fits a unique mechanical enclosure, with specific dimensions, aspect ratio, and even non-rectangular shapes.

Optical Bonding: This process involves filling the air gap between the LCD and the cover glass with a clear resin. It significantly reduces glare, improves sunlight readability, and prevents internal condensation. This is a vital feature for outdoor or high-humidity applications.

Enhanced Durability: Chuanhang Display can produce custom TFT LCD screen units with strengthened glass, hardened surface treatments, and extended temperature range components to withstand industrial, automotive, or outdoor environments.

Integrated Touch: Adding a touch panel, such as resistive, capacitive, or projective capacitive (PCAP), is a common customization. This can be seamlessly integrated into the display assembly.

Tailored Connectors and Interfaces: Customizing the interface (LVDS, MIPI, etc.) and connector location to simplify integration into your product's mainboard.

Sourcing a TFT LCD screen, especially a custom TFT LCD screen, requires a supplier with proven expertise and reliability. A company like Chuanhang Display brings more than just manufacturing capability to the table. They offer engineering support to help you select the right technology (e.g., IPS vs. TN), manage the complexities of the supply chain, and ensure consistent quality through rigorous testing protocols. For businesses looking to differentiate their products, this collaborative engineering approach is invaluable.

While newer technologies like OLED and MicroLED grab headlines, the TFT LCD screen is far from obsolete. Continuous improvements in areas like Mini-LED backlighting, which offers superior contrast and HDR performance, are keeping TFT LCDs highly competitive. Their unbeatable value proposition for a vast range of applications ensures they will remain a cornerstone of the display industry for years to come.

Q1: What is the main difference between a TFT LCD and an OLED screen?

A1: The fundamental difference is the light source. A TFT LCD screen requires a separate backlight unit (usually LEDs) to shine light through its liquid crystal layer. An OLED (Organic Light-Emitting Diode) is emissive, meaning each pixel generates its own light. This allows OLEDs to achieve perfect blacks by turning off individual pixels, leading to infinite contrast ratios, but they can be more expensive and susceptible to burn-in than LCDs.

Q2: Can a TFT LCD screen be viewed in direct sunlight?

A2: Standard TFT LCD screen modules perform poorly in direct sunlight due to washout from glare. However, high-brightness versions (1000 nits and above) are available. For the best sunlight readability, these high-brightness displays are often combined with optical bonding and strong anti-reflective coatings, a service offered by specialists like Chuanhang Display.

Q3: What does "optical bonding" do for a TFT LCD?

A3: Optical bonding is the process of laminating the cover glass directly to the TFT LCD screen using a clear optical adhesive. This eliminates the air gap, which reduces internal reflection, dramatically improves contrast in bright light, strengthens the display stack, and prevents condensation from forming between the layers.

Q4: How long is the typical lifespan of a TFT LCD screen?

A4: The typical lifespan of a TFT LCD screen is usually defined as the time it takes for the backlight's brightness to reduce to 50% of its original value. For standard LED-backlit TFTs, this is often in the range of 30,000 to 50,000 hours. Industrial-grade displays from manufacturers like Chuanhang Display can be configured with components rated for even longer lifespans.

Q5: Is it possible to integrate a touchscreen with a TFT LCD?

A5: Absolutely. Integrating a touchscreen is one of the most common requests. The main types are Resistive (pressure-based), Capacitive (touch-based, multi-touch capable), and Projected Capacitive (PCAP, the modern standard for smartphones). A supplier like Chuanhang Display can provide a fully integrated and tested TFT LCD screen with a touch panel, simplifying your assembly process.