In the world of electronics, the screen is often the most critical point of interaction between the user and the device. Whether it's a smartphone, a car dashboard, or an industrial control panel, the quality of the display directly impacts the user experience. At the heart of this interaction are two dominant display technologies: the OLED LCD module and the traditional LCD module. While the term "OLED LCD module" is technically a misnomer—as OLED (Organic Light-Emitting Diode) and LCD (Liquid Crystal Display) are distinct technologies—it is a common phrase used in searches by engineers and purchasers comparing their options. This article will demystify these technologies, explore their key differences, and guide you in selecting the ideal OLED LCD module solution for your application, with a focus on the offerings from Chuanhang Display.

To make an informed choice, it's essential to understand the fundamental operating principles behind each type of display module.

An LCD module relies on a backlight, typically composed of LEDs, that shines light through a series of layers. At the core is a layer of liquid crystals that can be manipulated by an electric current. These crystals act like tiny shutters, either allowing light to pass through or blocking it. They don't produce their own light. In front of the liquid crystals are color filters (red, green, and blue) that create the full-color image you see. The entire assembly is controlled by a driver IC, which is integrated into the module.

An OLED module, on the other hand, is fundamentally different. Each pixel in an OLED display is made from organic carbon-based compounds that emit their own light when an electric current is applied. This means there is no need for a separate backlight. When a pixel is turned off, it is completely black and consumes no power. This self-emissive characteristic is the source of OLED's most significant advantages. Companies like Chuanhang Display specialize in manufacturing both standard LCD modules and advanced OLED LCD module alternatives, providing a range of solutions for different design needs.

When it comes to pure image quality, the differences are stark.

Contrast Ratio: This is where OLED LCD module comparisons heavily favor OLED. Since OLED pixels can be completely turned off, they can achieve a theoretically infinite contrast ratio. Blacks are truly black, leading to a more vibrant, dynamic, and realistic image. In an LCD, the backlight is always on, and even the best local dimming techniques cannot completely block all light, resulting in "grayish" blacks and a lower contrast ratio.

Viewing Angles: OLED technology also excels here. Because each pixel emits light directly, the image remains consistent and color-accurate even at extreme viewing angles. LCDs can suffer from color shifting, contrast loss, and brightness reduction when viewed from the side, as the light from the backlight has to travel through multiple layers at an angle.

Color Gamut and Brightness: Historically, LCDs had an advantage in peak brightness, making them more suitable for very sunny environments. However, OLED technology has advanced significantly. Modern OLED LCD module products from leading suppliers can achieve high brightness levels and cover a wide color gamut, such as DCI-P3, delivering stunning color reproduction.

Power efficiency is a critical factor, especially for battery-powered devices.

OLED displays are inherently more power-efficient than LCDs in many scenarios. Their power consumption is directly dependent on the content being displayed. Since black pixels are off and consume no power, showing a dark interface or a mostly black screen can significantly extend battery life. In contrast, an LCD's backlight is always draining power at a relatively constant rate, regardless of whether the screen is showing a white image or a black one.

Furthermore, the absence of a backlight unit makes OLED LCD module constructs much thinner and lighter. This allows for sleeker, more modern device designs. The flexibility of OLED substrates also opens the door for innovative form factors, such as curved and even foldable displays, which are impossible to achieve with traditional rigid LCD panels. Chuanhang Display leverages this advantage to provide ultra-thin OLED LCD module options for space-constrained applications.

This is an area where LCDs have traditionally held an advantage, though the gap is narrowing.

The most common concern with OLED technology is "burn-in" or image retention. This is a phenomenon where static images displayed for very long periods can cause a permanent, ghost-like shadow on the screen. This is due to the gradual degradation of the organic materials in the pixels that are kept on at high brightness for extended times. LCDs are generally immune to this issue.

Additionally, the organic materials in OLEDs have a finite lifespan, particularly the blue sub-pixels, which degrade faster. This can lead to color shifts over a very long period. LCDs, with their inorganic LED backlights, typically have a longer overall lifespan and are less susceptible to permanent image retention.

However, it's important to note that modern OLED LCD module manufacturers have implemented several mitigation techniques. These include pixel shifting, dynamic brightness scaling, and sophisticated algorithms that help to drastically reduce the risk of burn-in for typical usage patterns. For most consumer applications, this is no longer a major practical concern.

So, how do you choose? The decision hinges on your application's specific requirements.

Choose an OLED module if:

Your priority is superior image quality with perfect blacks and high contrast (e.g., premium smartphones, VR headsets, high-end televisions).

You need wide viewing angles (e.g., automotive displays, public kiosks).

Power efficiency is paramount, and your user interface is predominantly dark (e.g., smartwatches, portable medical devices).

You require a very thin or flexible form factor.

Choose an LCD module if:

Your project has a tight cost constraint, as LCDs are generally less expensive.

The screen will display static content for very long, uninterrupted periods (e.g., industrial control panels, scoreboards).

You need very high sustained brightness for outdoor use in direct sunlight.

Long-term reliability without any risk of burn-in is the absolute top priority.

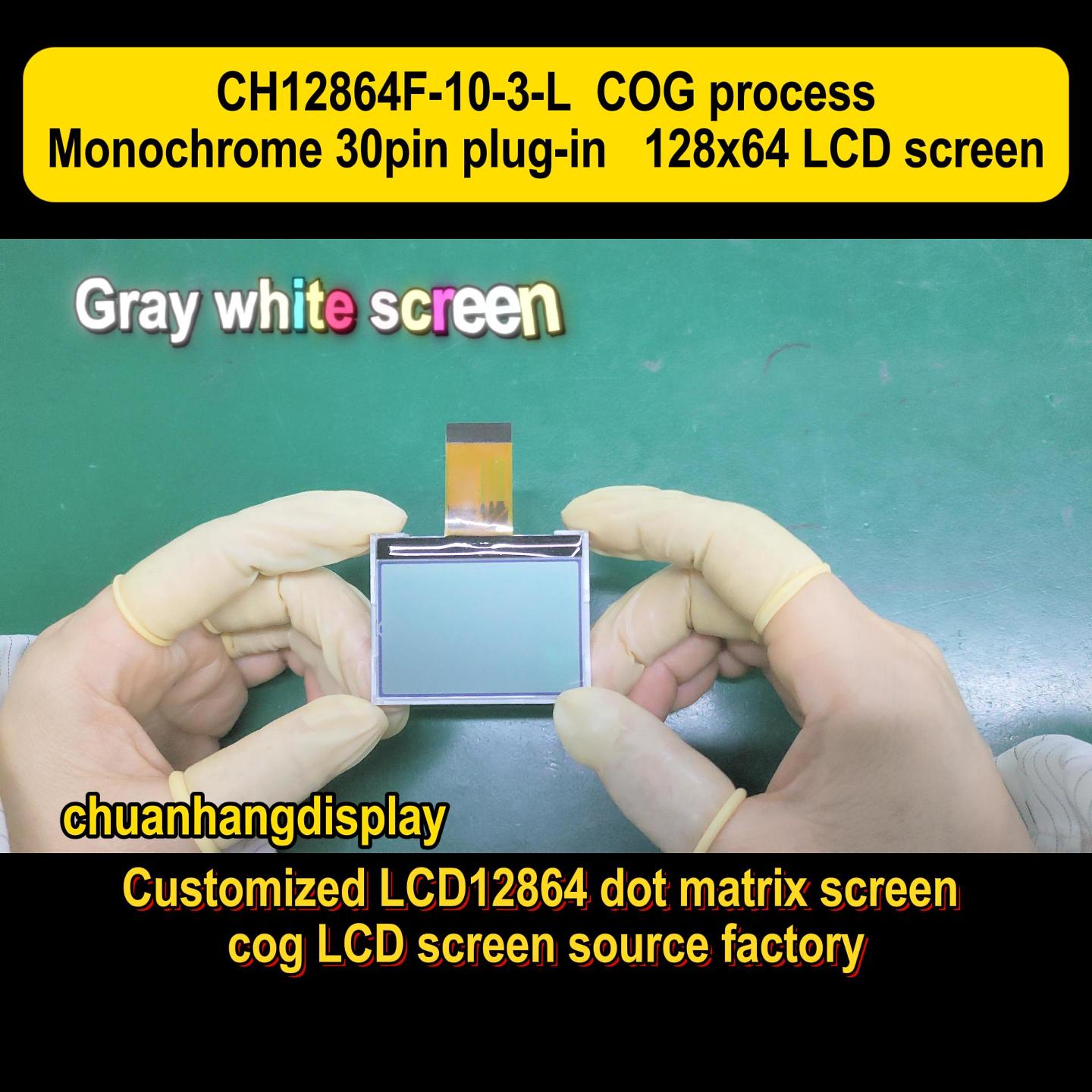

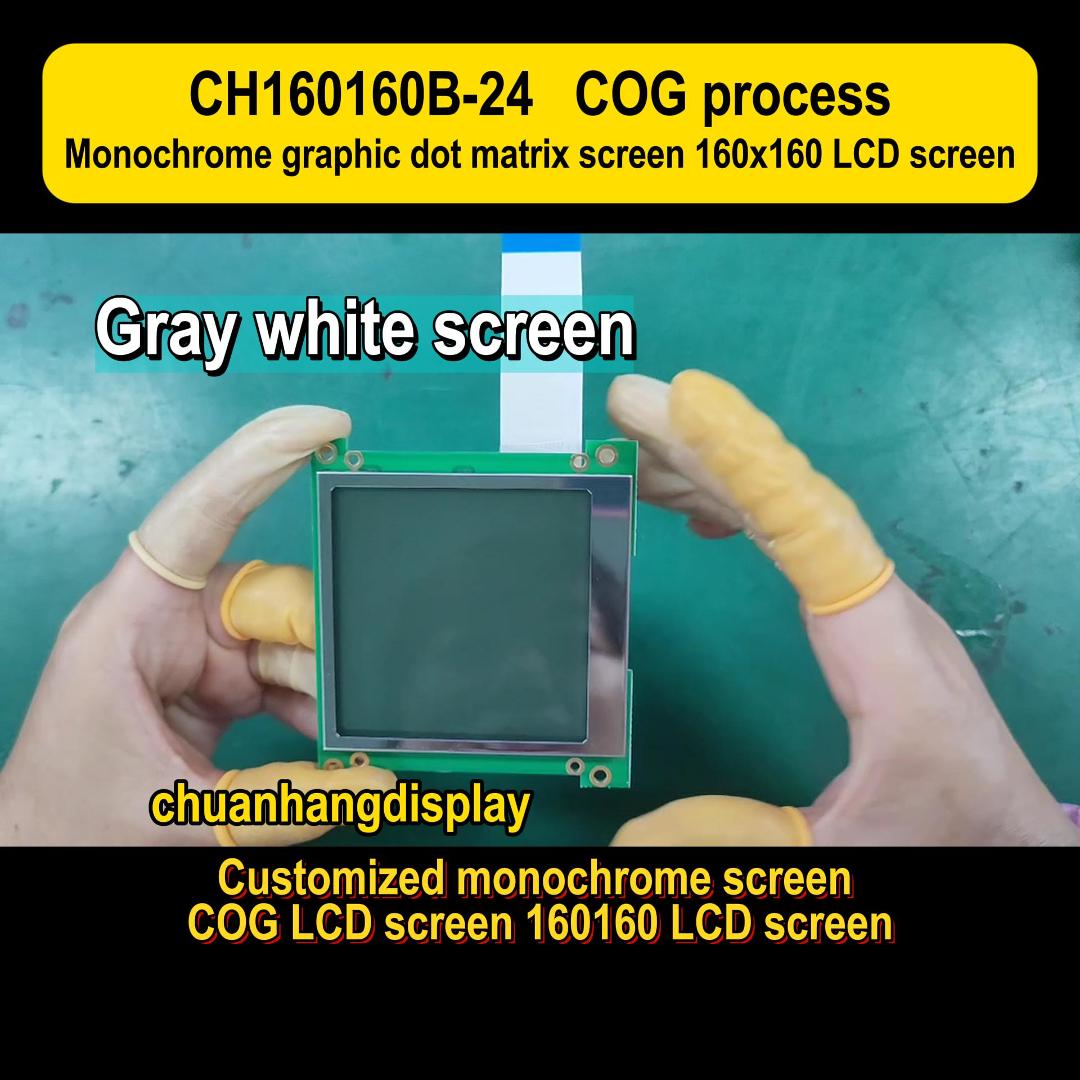

When sourcing components, working with an experienced manufacturer like Chuanhang Display is crucial. They can provide expert guidance on whether a traditional LCD or a modern OLED LCD module is the right fit, ensuring you get the best performance and value for your specific project.

Q1: Which technology is easier on the eyes for long-term use?

A: This is subjective. OLEDs offer flicker-free dimming (using Pulse Width Modulation at very high frequencies or DC dimming) and no backlight bleed, which can be easier for some. However, some users are sensitive to the PWM dimming on certain OLEDs. LCDs with high-quality, flicker-free backlights can also be very comfortable. The content and brightness setting are often more significant factors.

Q2: Why is my OLED screen showing a temporary afterimage?

A: This is usually "image retention," which is temporary and will fade, unlike permanent "burn-in." Modern OLED LCD module controllers have features to clear this quickly. To prevent it, avoid static images at high brightness for extended periods and use features like screen savers.

Q3: Can I replace an LCD module with an OLED module directly?

A: Not directly. The power requirements, signal interfaces (e.g., MIPI DSI vs. LVDS), and driver electronics are different. A design change on the mainboard is almost always required to accommodate an OLED LCD module.

Q4: Are OLED modules suitable for industrial and automotive applications?

A: Absolutely. With advancements in durability, lifespan, and high-brightness options, OLED LCD module technology is increasingly being adopted in automotive dashboards and industrial HMIs. Their wide viewing angles and superior readability are major benefits. Suppliers like Chuanhang Display often offer ruggedized versions designed for these harsh environments.

Q5: How does cost compare in the long run?

A: While the upfront cost of an OLED is higher, the Total Cost of Ownership (TCO) can be lower for some applications. The energy savings in a battery-powered device over its lifetime can offset the initial price. Furthermore, the potential for enabling a thinner, lighter, and more premium product can lead to higher market appeal and sales.