In today's tech-driven era, LCD displays are everywhere—from smartphones and televisions to industrial equipment and medical devices. But have you ever wondered how these sleek screens come to life? At the heart of this innovation lies the LCD display factory, a hub of precision engineering and mass production. These facilities are not just assembly lines; they are complex ecosystems where cutting-edge technology meets rigorous quality control. In this article, we'll delve into seven key aspects of an LCD display factory, exploring everything from manufacturing processes to common challenges. Whether you're a tech enthusiast, a business owner sourcing displays, or simply curious, this deep dive will shed light on what makes these factories tick. Plus, we'll highlight how brands like Chuanhang Display excel in this competitive landscape. By the end, you'll have a comprehensive understanding of the inner workings of an LCD display factory, including the typical problems they face and how they overcome them.

An LCD display factory is a specialized industrial facility dedicated to the production of liquid crystal display (LCD) panels and modules. These factories integrate advanced machinery, automated systems, and skilled labor to transform raw materials into functional displays. The process begins with glass substrates, which are coated, etched, and assembled with layers of liquid crystals, polarizers, and backlight units. The goal is to create high-resolution, energy-efficient screens for various applications, such as consumer electronics, automotive dashboards, and healthcare monitors. In a typical LCD display factory, operations are divided into stages like design, fabrication, testing, and packaging. For instance, Chuanhang Display operates state-of-the-art factories that emphasize innovation and sustainability, ensuring each display meets global standards. Understanding the basics of an LCD display factory is crucial because it highlights the intersection of technology and manufacturing, driving the devices we rely on daily.

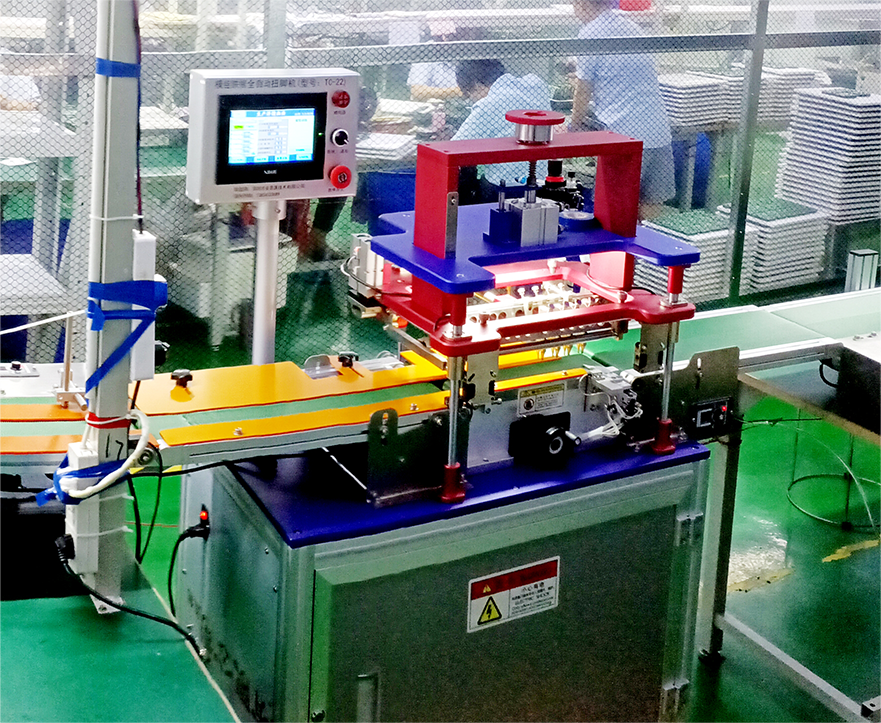

The manufacturing process in an LCD display factory is a meticulous sequence that ensures precision and efficiency. It typically involves several key steps: First, glass substrate preparation, where large sheets of glass are cleaned and coated with conductive materials like indium tin oxide (ITO). This forms the base for the liquid crystal layer. Next, photolithography and etching create intricate circuit patterns on the glass, defining pixels and electrodes. Then, the liquid crystal material is injected between two glass layers, and polarizers are applied to control light transmission. The assembly phase includes adding backlight units—often LEDs—to illuminate the display. In a modern LCD display factory, automation plays a vital role; robots handle tasks like alignment and bonding to minimize human error. For example, at Chuanhang Display, the process integrates real-time monitoring to maintain consistency. Finally, each unit undergoes initial testing before packaging. This streamlined approach in an LCD display factory ensures high yield rates and reduces waste, making it a cornerstone of the electronics supply chain.

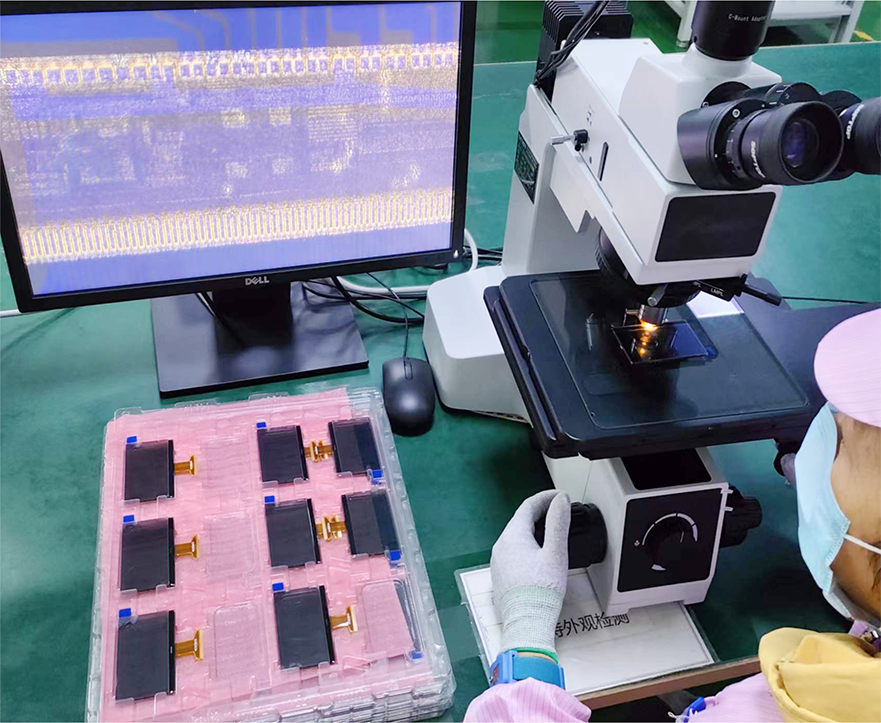

Quality control is paramount in an LCD display factory to deliver reliable, durable products. This involves multiple layers of inspection and adherence to international standards like ISO 9001 and RoHS. In a typical LCD display factory, quality checks start with raw material verification, ensuring components like glass and liquid crystals meet specifications. During production, automated optical inspection (AOI) systems scan for defects such as dead pixels, uneven backlighting, or color shifts. Environmental testing simulates extreme conditions—heat, humidity, and vibration—to assess durability. For instance, Chuanhang Display implements Six Sigma methodologies in their LCD display factory to minimize variations and defects. Additionally, functional tests verify aspects like response time, brightness, and viewing angles. This rigorous approach not only enhances customer satisfaction but also reduces returns and recalls. By maintaining high standards, an LCD display factory can build trust and compete in global markets, where quality often dictates success.

Despite advanced technology, an LCD display factory often encounters common problems that can impact production and product quality. One frequent issue is dead or stuck pixels, where individual pixels fail to change color, resulting from contamination or manufacturing errors. This is typically addressed through pixel-refreshing techniques or replacement during quality checks. Another challenge is backlight bleeding, where light leaks from the edges of the display, causing uneven illumination. In an LCD display factory, this is mitigated by improving sealing processes and using higher-quality diffusers. Color uniformity problems, such as tint variations across the screen, can arise from inconsistencies in liquid crystal alignment or backlight intensity. Factories like Chuanhang Display employ calibration tools to standardize colors. Additionally, moisture ingress and electrostatic discharge (ESD) can damage components during assembly, leading to failures. To combat this, an LCD display factory uses controlled environments and anti-static measures. Supply chain disruptions, like material shortages, also pose risks, requiring robust inventory management. By understanding these common problems, an LCD display factory can implement proactive solutions, ensuring smoother operations and higher-quality outputs.

Automation and innovation are driving forces in a modern LCD display factory, enhancing efficiency and enabling new capabilities. Robotics and AI systems handle repetitive tasks such as component placement, soldering, and testing, reducing labor costs and human error. For example, in an LCD display factory, automated guided vehicles (AGVs) transport materials between stations, while machine learning algorithms optimize production schedules based on real-time data. Innovation extends to materials science, with developments in flexible LCDs and eco-friendly components reducing environmental impact. Brands like Chuanhang Display invest in R&D to integrate features like touch functionality and higher resolutions, keeping their LCD display factory at the forefront of industry trends. Moreover, the adoption of IoT devices allows for predictive maintenance, minimizing downtime. This focus on automation and innovation not only boosts productivity in an LCD display factory but also supports customization for diverse applications, from smart homes to industrial automation.

Sustainability is increasingly critical in an LCD display factory, as consumers and regulators demand eco-friendly products. Factories implement practices like energy-efficient lighting and machinery to reduce carbon footprints. For instance, many LCD display factory facilities use solar power or waste heat recovery systems. Water recycling is common in processes like cleaning and etching, minimizing resource consumption. Additionally, hazardous materials, such as mercury in older backlights, are being phased out in favor of LED alternatives. Chuanhang Display, for example, emphasizes green manufacturing in their LCD display factory by adhering to RoHS directives and promoting recyclable packaging. Waste management programs ensure that scrap materials are repurposed or disposed of safely. These efforts not only comply with regulations but also enhance brand reputation. By prioritizing sustainability, an LCD display factory can contribute to a circular economy while meeting market demands for responsible production.

In the competitive landscape of display manufacturing, brands like Chuanhang Display stand out by leveraging their expertise in operating an efficient LCD display factory. Chuanhang Display focuses on customer-centric solutions, offering customizable displays for niches like gaming, medical, and automotive industries. Their LCD display factory incorporates advanced quality control systems and agile production lines, allowing for quick turnaround times without compromising on performance. By investing in continuous innovation, Chuanhang Display stays ahead with products featuring higher brightness, wider viewing angles, and better durability. Moreover, their global supply chain network ensures reliable material sourcing, reducing the impact of disruptions. This commitment to excellence makes Chuanhang Display a trusted partner for businesses seeking high-quality LCDs. Learning from such brands highlights how a well-managed LCD display factory can drive industry leadership through a blend of technology, quality, and sustainability.

An LCD display factory is more than just a production site; it's a dynamic environment where technology, quality, and innovation converge. From the intricate manufacturing processes to the common challenges like dead pixels and backlight bleeding, these factories continuously evolve to meet global demands. Brands like Chuanhang Display exemplify how a focus on automation, sustainability, and customer needs can lead to success in this field. As we've explored through these seven insights, understanding the workings of an LCD display factory provides valuable perspective on the devices that shape our digital world. Whether you're involved in sourcing or simply curious, this knowledge underscores the importance of these facilities in driving technological progress. If you're considering partnerships or purchases, remember that a reliable LCD display factory is key to delivering the crisp, reliable displays we depend on every day.