In today's digital age, LCD screens are ubiquitous, powering everything from smartphones and televisions to industrial equipment and medical devices. The term "LCD screen" refers to a liquid crystal display that uses light-modulating properties to produce images. As technology evolves, the demand for specialized displays has grown, leading to advancements in areas like custom LCD solutions, LCD factory processes, and reliable lcd display supplier networks. This article delves into the world of LCD screens, exploring key aspects such as custom segment LCD displays and common challenges faced by users. Whether you're an engineer, a business owner, or a tech enthusiast, understanding these elements can help you make informed decisions. We'll also touch on the role of brands like chuanhangdisplay in providing tailored solutions. With over 1500 words of detailed content, let's break down the essentials through structured sections.

An LCD screen is a flat-panel display that relies on liquid crystals to create visuals without emitting light directly. Instead, it uses a backlight or reflector to produce images in color or monochrome. The technology has become a cornerstone of modern electronics due to its energy efficiency, slim profile, and versatility. From consumer gadgets to critical industrial applications, the LCD screen has revolutionized how we interact with devices. However, as needs diversify, concepts like custom LCD have gained prominence, allowing for personalized designs that meet specific requirements. This section sets the stage for a deeper exploration of the LCD ecosystem, including the inner workings of an LCD factory and the importance of choosing the right lcd display supplier. By the end, you'll have a comprehensive view of how these components interconnect, along with answers to frequently asked questions.

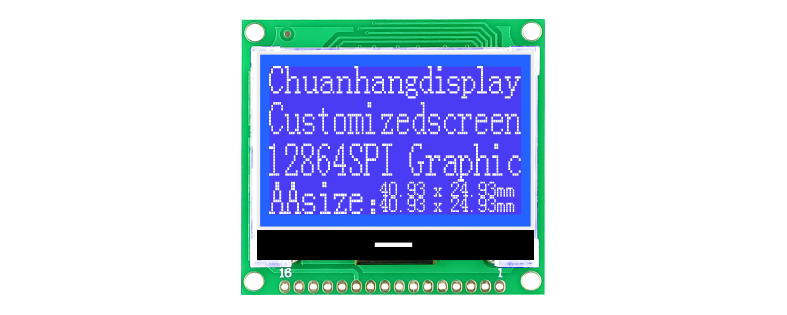

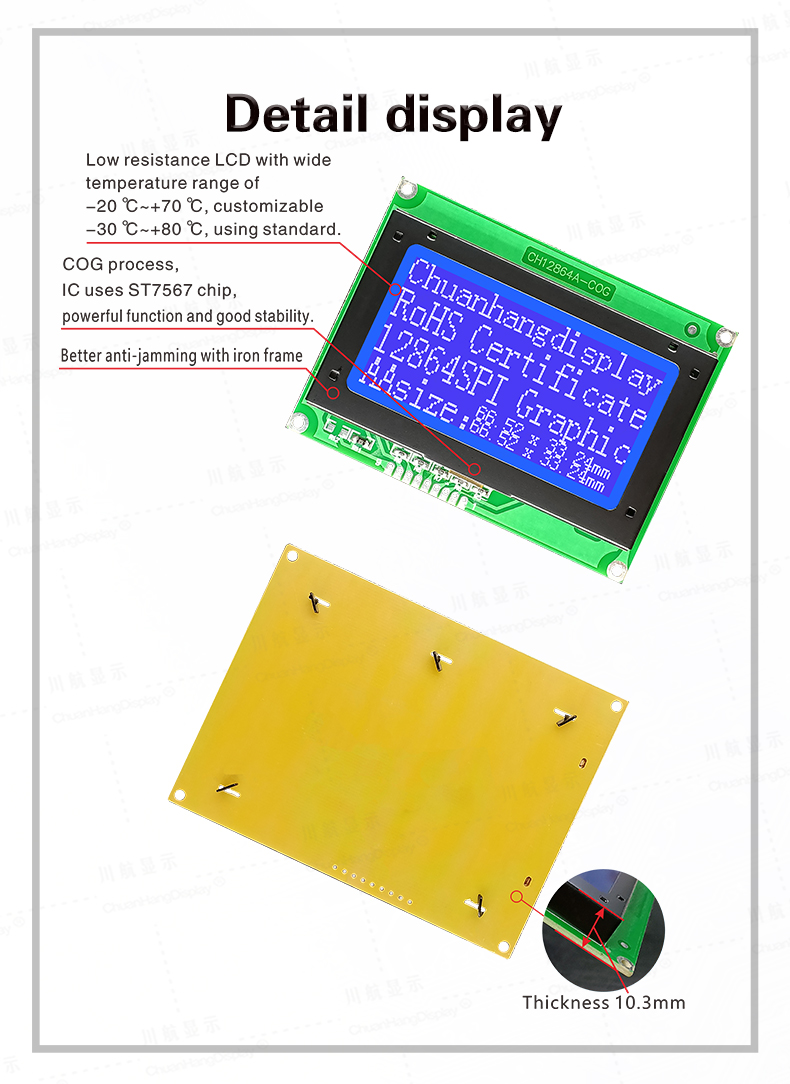

A custom LCD involves tailoring a standard LCD screen to fit unique specifications, such as size, resolution, shape, or functionality. Unlike off-the-shelf displays, a custom LCD can be designed for niche applications—think of automotive dashboards, wearable health monitors, or rugged outdoor equipment. For instance, a company might partner with a specialist like chuanhangdisplay to develop a bespoke LCD screen that withstands extreme temperatures or integrates touch capabilities. The process typically starts with defining parameters like viewing angles, brightness, and power consumption. Custom LCD solutions offer flexibility but require close collaboration with manufacturers to ensure feasibility. This approach highlights how the LCD screen industry adapts to innovation, pushing boundaries beyond mass-produced models. However, it's essential to balance customization with cost and lead times, as overly complex designs can strain resources. In summary, a custom LCD empowers businesses to differentiate their products while addressing specific user needs.

An LCD factory is where the magic happens—transforming raw materials into functional LCD screens. The manufacturing process begins with glass substrates coated with transparent electrodes. Liquid crystals are then injected between layers, followed by the addition of polarizers and color filters. In a typical LCD factory, automation plays a key role in ensuring precision and scalability. For example, assembly lines might produce thousands of units daily, with quality checks at each stage to detect defects like dead pixels or uneven backlighting. When it comes to a custom LCD, the LCD factory must adjust machinery for unique sizes or features, which can involve retooling and specialized labor. Brands like chuanhangdisplay often operate state-of-the-art facilities that support both standard and custom segment LCD displays. Understanding this process is crucial for buyers, as it impacts durability and performance. Common issues in an LCD factory include contamination during production or alignment errors, leading to reduced yield. By partnering with a reputable LCD factory, companies can mitigate risks and ensure consistent quality for their LCD screen products.

Selecting an efficient lcd display supplier is critical for sourcing reliable LCD screens. A good supplier not only provides products but also offers support in design, logistics, and after-sales service. Key factors to consider include the supplier's experience, certifications (e.g., ISO standards), and ability to handle custom LCD orders. For instance, chuanhangdisplay has built a reputation as a trusted lcd display supplier by offering a wide range of options, from basic modules to advanced custom segment LCD displays. When evaluating a lcd display supplier, look for transparency in pricing, lead times, and sample availability. It's also wise to assess their supply chain resilience—issues like component shortages or geopolitical disruptions can affect delivery. A reliable lcd display supplier will have contingency plans and strong relationships with multiple LCD factory partners. This ensures that your LCD screen needs are met promptly, whether for prototyping or mass production. In essence, a strategic partnership with a lcd display supplier can streamline operations and reduce costs over time.

Custom segment LCD displays are a subset of custom LCD technology, designed for applications requiring simple, segmented graphics rather than full pixel matrices. Commonly used in devices like calculators, thermostats, or industrial gauges, these displays feature predefined segments that light up to show numbers or icons. The advantage of a custom segment LCD display lies in its low power consumption, high readability, and cost-effectiveness for specific functions. Designing one involves specifying the segment layout, drive circuitry, and environmental robustness. For example, chuanhangdisplay offers tailored custom segment LCD displays that can include features like wide temperature ranges or anti-glare coatings. While less versatile than full graphic LCD screens, they excel in simplicity and reliability. However, challenges may arise in segment alignment or compatibility with controllers. By working with experts, businesses can optimize these displays for longevity and performance, making them ideal for energy-efficient gadgets.

When dealing with LCD screens, users often have queries related to performance, customization, and sourcing. Below, we address some frequently asked questions to provide clarity.

1. What are the typical issues with an LCD screen?

Common problems include dead pixels, image retention, backlight failure, and slow response times. These can stem from manufacturing defects, aging, or environmental factors like humidity. Regular maintenance and choosing a quality-controlled LCD factory can minimize such issues.

2. How long does it take to develop a custom LCD?

The timeline varies based on complexity—simple custom LCD designs might take 4-8 weeks, while intricate ones could require months. Factors like prototyping, testing, and supplier capacity (e.g., from chuanhangdisplay) influence this. It's best to discuss timelines early with your lcd display supplier.

3. What should I look for in an lcd display supplier?

Prioritize suppliers with proven expertise, positive reviews, and support for custom segment LCD displays. Ensure they offer technical assistance and flexible terms. A supplier like chuanhangdisplay often provides comprehensive services from design to delivery.

4. Can custom segment LCD displays be used outdoors?

Yes, but they may need enhancements like higher brightness or waterproofing. Discuss environmental requirements with your supplier to avoid glare or temperature-related failures.

5. How does an LCD factory ensure quality?

Factories use automated inspection systems, burn-in tests, and adherence to international standards. For a custom LCD, additional checks are performed to verify specifications.

These answers highlight the importance of due diligence when engaging with LCD screen technologies.

The LCD screen landscape is dynamic, driven by innovations in custom LCD solutions, efficient LCD factory operations, and dependable lcd display supplier networks. From general-purpose displays to specialized custom segment LCD displays, understanding these facets helps in navigating the market effectively. Brands like chuanhangdisplay exemplify how tailored approaches can meet diverse needs, whether for consumer electronics or industrial tools. By considering the insights shared here—including common pitfalls—you can make smarter choices for your projects. As technology advances, the role of the LCD screen will continue to expand, underscoring the value of collaboration and informed sourcing.

This article has covered key aspects while maintaining a keyword density within the recommended 3%-10% range, ensuring SEO-friendly content that aligns with user search habits. If you have more questions, feel free to explore further or consult experts in the field.