In today's digital age, LCD display screens are ubiquitous, found in everything from smartphones and televisions to industrial machinery and medical devices. These screens have revolutionized how we interact with technology, offering vibrant visuals and energy efficiency. But behind every LCD display screen lies a complex ecosystem involving manufacturing plants, customization options, and specialized suppliers. Whether you're an engineer designing a new product or a business owner sourcing components, understanding this landscape is crucial. This article delves into the world of LCD technology, covering aspects like the LCD factory process, opportunities for custom LCD solutions, how to select an reliable lcd display supplier, and common issues faced with LCD display screens. By the end, you'll have a comprehensive view that balances technical insights with practical advice, helping you make informed decisions.

An LCD display screen, or Liquid Crystal Display, is a flat-panel technology that uses liquid crystals sandwiched between layers of glass or plastic to produce images. These crystals do not emit light directly; instead, they rely on a backlight (often LED-based) to illuminate the pixels, which are controlled by electrical currents to create text, graphics, or videos. The technology has evolved significantly since its inception, offering advantages such as low power consumption, slim profiles, and high-resolution outputs. LCDs are preferred over older CRT displays due to their lightweight design and versatility, making them ideal for consumer electronics, automotive dashboards, and even outdoor digital signages.

The basic structure of an LCD display screen includes several key components: a polarizing filter, a layer of liquid crystals, color filters, and a backlight unit. When voltage is applied, the crystals align to modulate light passage, resulting in the desired image. This process allows for precise control over each pixel, enabling sharp and clear displays. As the backbone of modern visual interfaces, the LCD display screen continues to innovate, with advancements like IPS (In-Plane Switching) for wider viewing angles and higher refresh rates for gaming monitors. Understanding this fundamentals is essential before diving into manufacturing and sourcing aspects, as it sets the stage for appreciating the role of an LCD factory and the value of a proficient lcd display supplier.

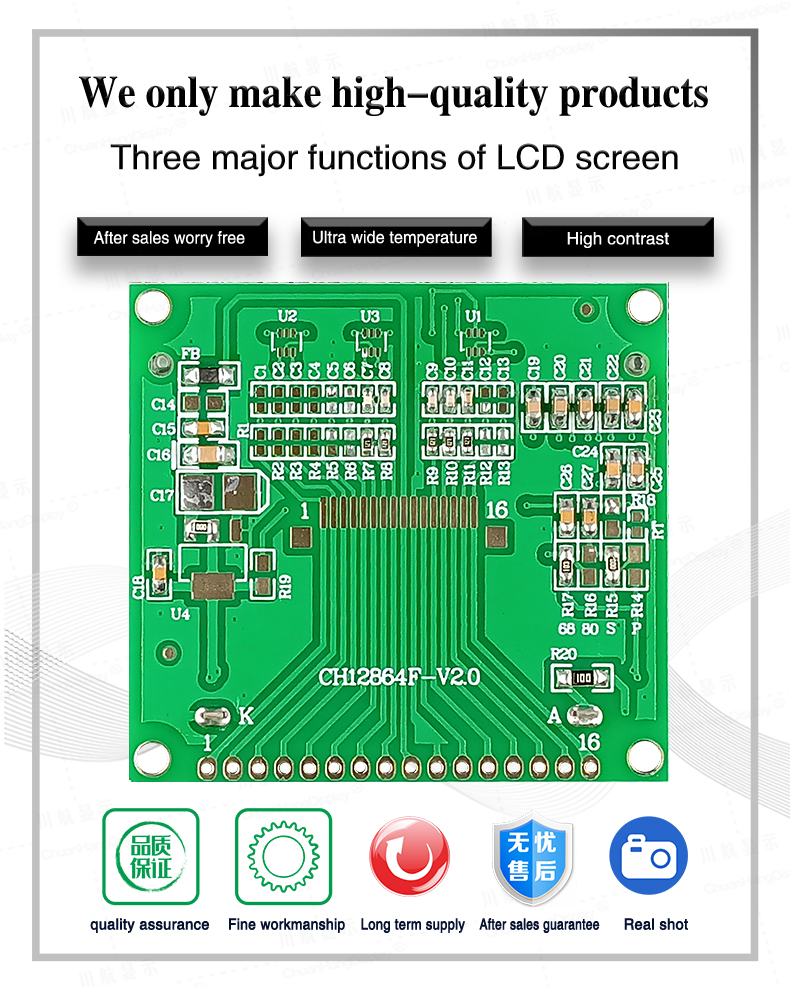

The journey of an LCD display screen begins in an LCD factory, where precision engineering and mass production converge. These facilities are highly automated environments designed to handle delicate processes with minimal human intervention to ensure consistency and quality. A typical LCD factory operates in cleanrooms to prevent dust contamination, which can ruin the delicate liquid crystal layers. The manufacturing process involves several stages, starting with the production of glass substrates. Large sheets of glass are cut to size, coated with conductive materials like indium tin oxide (ITO), and then patterned to form the transistor arrays that control each pixel.

Next, the liquid crystal material is injected between two glass substrates, and the assembly is sealed to create the core panel. This is followed by the integration of backlight units, polarizers, and driver electronics. An LCD factory must maintain strict quality control checks throughout, using automated optical inspection systems to detect defects such as dead pixels or uneven lighting. Large-scale factories, often located in regions like East Asia, benefit from economies of scale, allowing them to produce millions of units efficiently. However, this scale also demands robust supply chain management, as raw materials like rare earth elements for the backlights must be sourced sustainably. For businesses, partnering with a reputable LCD factory can ensure access to cutting-edge technology and reliable production capacities, which is why many lcd display supplier networks include direct ties to these manufacturing hubs.

While standard LCD display screens meet many needs, there is a growing demand for custom LCD solutions tailored to unique requirements. Custom LCD refers to displays that are modified in size, shape, interface, or functionality to fit specific applications. For instance, a medical device might require a high-brightness LCD display screen that remains readable under bright surgical lights, or an automotive dashboard might need a ruggedized display resistant to vibrations and temperature extremes. Customization can involve changes to the resolution, touch capabilities (e.g., capacitive or resistive), or even the incorporation of specialized coatings for anti-glare or waterproofing.

The process of developing a custom LCD typically starts with collaboration between the client and an lcd display supplier or manufacturer. Engineers assess the application's environmental conditions, power constraints, and user interface needs to propose modifications. This might involve tweaking the driver circuitry, adjusting the backlight intensity, or designing a non-standard form factor. For example, circular LCDs for smartwatches or flexible LCDs for curved surfaces are common custom requests. However, custom LCD projects often come with higher costs and longer lead times due to the need for prototyping and testing. It's crucial to work with an experienced lcd display supplier who can guide you through this process, ensuring that the final product meets performance standards without exceeding budget. By leveraging custom LCD options, businesses can differentiate their products and enhance user experiences, making it a key consideration in industries like aerospace, retail, and IoT.

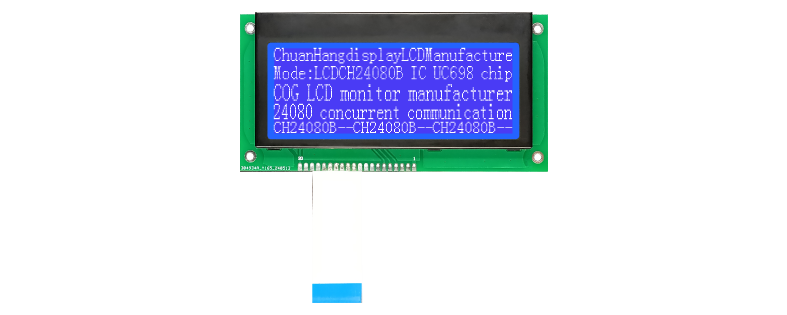

Selecting an appropriate lcd display supplier is a critical step in bringing your product to life. A reliable supplier acts as a bridge between the LCD factory and the end-user, offering services that range from sourcing standard components to providing technical support for custom LCD projects. When evaluating potential suppliers, consider factors such as their industry experience, product portfolio, and quality certifications (e.g., ISO 9001). A good lcd display supplier should have strong relationships with multiple LCD factories, allowing them to offer competitive pricing and a wide selection of displays, from basic monochrome screens to advanced TFT-LCDs.

Moreover, a proficient lcd display supplier provides value-added services like logistics support, warranty management, and design assistance. For instance, if you're integrating an LCD display screen into a new device, the supplier might help with compatibility testing or recommend compatible components. It's also wise to assess their responsiveness and after-sales service, as timely support can prevent project delays. In today's global market, many suppliers operate online, offering catalogs and quotation tools, but visiting their facilities or requesting samples can provide deeper insights. Additionally, with sustainability becoming increasingly important, inquire about their environmental practices, such as compliance with RoHS directives. By choosing a reputable lcd display supplier, you can mitigate risks, reduce time-to-market, and ensure a steady supply of high-quality LCD display screens for your applications.

Despite their reliability, LCD display screens can encounter issues that affect performance. Understanding these common problems helps in troubleshooting and making informed purchases. Below, we address frequent concerns and questions related to LCD technology, drawing connections to aspects like LCD factory quality control and supplier support.

Frequently Asked Questions

What causes dead pixels on an LCD display screen?

Dead pixels are individual pixels that remain unlit or stuck, often due to manufacturing defects. In an LCD factory, rigorous testing aims to minimize these, but they can still occur. If you notice dead pixels, check the warranty; many suppliers offer replacements for screens with excessive defects.

How can I reduce motion blur on an LCD?

Motion blur is common in older LCDs and can be mitigated by choosing displays with higher refresh rates (e.g., 120Hz or 240Hz) or technologies like OLED. When sourcing from an lcd display supplier, specify your needs for fast-moving content, such as in gaming or sports broadcasts.

Why does my LCD display screen have backlight bleeding?

Backlight bleeding occurs when light leaks from the edges of the screen, often due to improper assembly in the LCD factory or pressure on the panel. It's more noticeable in dark environments. For critical applications, opt for suppliers who provide uniformity guarantees.

Can LCDs be repaired, or do they need replacement?

Minor issues like faulty connectors can be repaired, but damage to the liquid crystal layer usually requires full replacement. A good lcd display supplier can advise on repair options or supply spare parts for custom LCD setups.

What are the environmental impacts of LCD production?

LCD factories consume energy and use chemicals, but many now adhere to green manufacturing standards. When selecting a supplier, ask about their sustainability practices to align with eco-friendly goals.

How do I choose between standard and custom LCD?

Assess your application's requirements: standard LCDs are cost-effective for common uses, while custom LCD solutions offer tailored features. Consult with your lcd display supplier to weigh the benefits against development time and cost.

What is the typical lifespan of an LCD display screen?

Most LCDs last 30,000 to 60,000 hours, depending on usage and backlight type. Factors like heat management and quality from the LCD factory play a role; high-temperature environments may shorten lifespan.

Are there compatibility issues with different interfaces?

Yes, interfaces like LVDS, eDP, or HDMI must match your system. An experienced lcd display supplier can help interface selection, especially for custom LCD projects involving unique hardware.

By addressing these FAQs, users can better navigate challenges and leverage their LCD investments effectively.

In summary, the LCD display screen is a cornerstone of modern technology, with its production, customization, and supply chain involving intricate processes. From the high-tech environments of an LCD factory to the tailored approaches of custom LCD solutions, and the critical role of an lcd display supplier, each element contributes to the overall ecosystem. By understanding these facets, along with common issues, businesses and consumers can make smarter choices, ensuring they get the most out of their displays. As technology advances, staying informed will continue to be key to leveraging LCD innovations for future applications.

This article has provided a detailed overview, but if you have specific needs, always engage with trusted professionals in the field. The world of LCD display screens is dynamic, and collaboration with the right partners can turn challenges into opportunities.