In the world of consumer electronics, industrial equipment, and medical devices, the screen is often the primary interface between human and machine. The quality of this experience hinges directly on the LCD manufacturer responsible for its production. Choosing the right manufacturing partner is a critical decision that impacts product performance, reliability, and overall cost. This article delves into the core aspects of a professional LCD manufacturer and outlines the common challenges faced during selection and integration.

A reputable LCD manufacturer is much more than a simple assembly line. It is a hub of advanced technology and precise engineering. The process begins with the fabrication of thin-film transistors (TFT) on a glass substrate, creating the active matrix that controls each individual pixel. This is followed by the deposition of liquid crystal material, polarizers, and color filters.

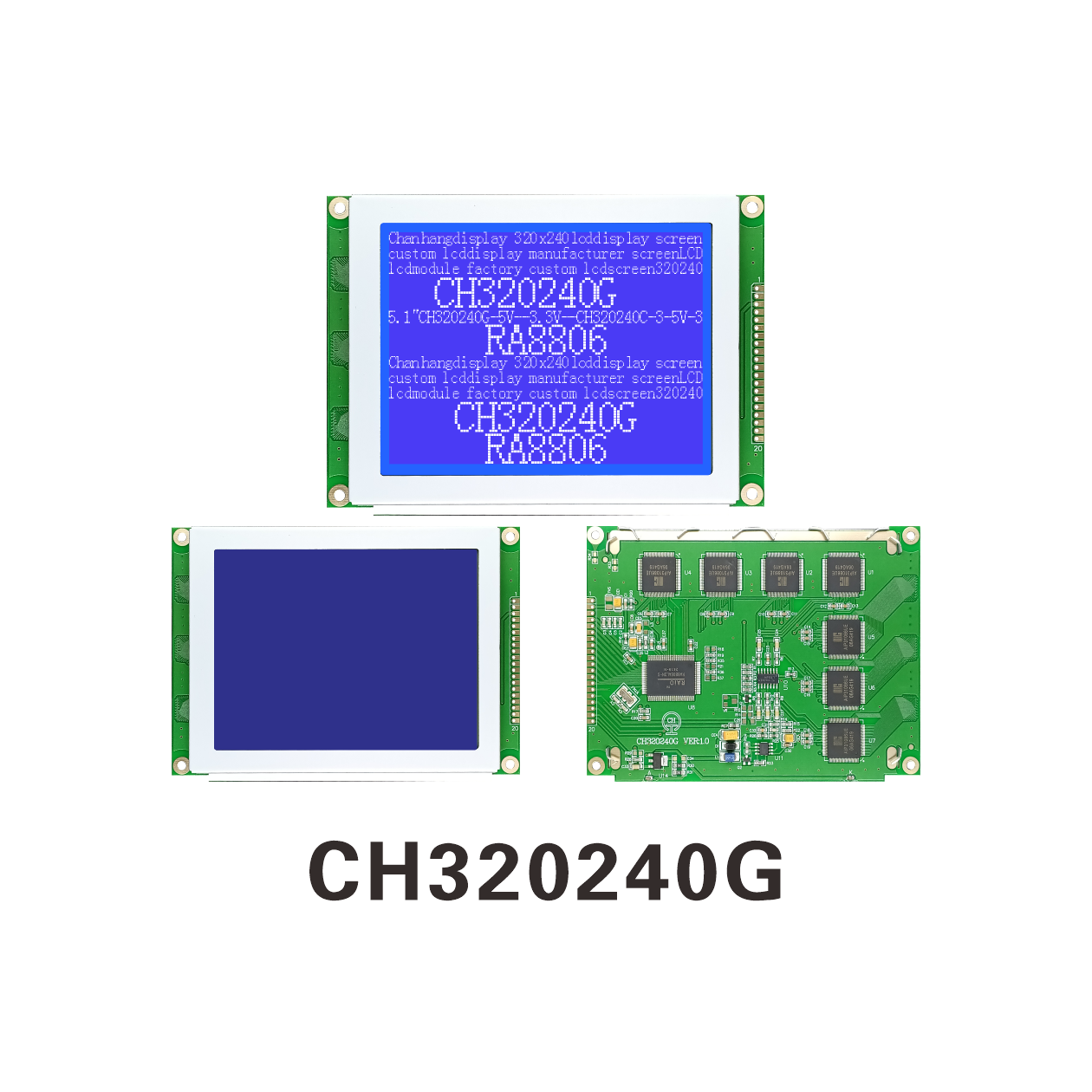

Key technological differentiators include the type of LCD technology offered. While Twisted Nematic (TN) panels offer fast response times, In-Plane Switching (IPS) technology provides superior color accuracy and wide viewing angles, making it a favorite for high-end applications. Vertical Alignment (VA) panels strike a balance with better contrast ratios. A leading LCD manufacturer like Chuanhang Display typically masters multiple technologies, offering clients tailored solutions based on their specific needs for viewing angle, response time, color gamut, and sunlight readability.

The true mettle of an LCD manufacturer is tested in its manufacturing capabilities and unwavering commitment to quality control. Capabilities are often measured by the generations of their production lines (e.g., G8.5), which determines the maximum size of the glass substrates they can process, directly influencing efficiency and cost for larger panels.

Quality control is an end-to-end process. It starts with the inspection of raw materials and continues through every stage of production. Automated Optical Inspection (AOI) systems scan for defects in the TFT array, and rigorous testing protocols check for visual imperfections like dead pixels, Mura (clouding), and backlight bleeding. A trustworthy manufacturer will have certifications like ISO 9001, ensuring standardized processes, and its products may comply with various international safety and environmental standards (UL, RoHS, REACH). This rigorous QC minimizes the risk of defective units reaching the end customer.

Off-the-shelf displays rarely meet the exact requirements of a specialized product. Therefore, a significant aspect of choosing an LCD manufacturer is their ability to provide customization and value-added services. This goes beyond just changing the size and resolution.

Customization can include:

Optical Bonding: Laminating the cover glass directly to the LCD to reduce glare, enhance sunlight readability, and prevent internal condensation.

Specialized Cover Glasses: Incorporating anti-reflective, anti-glare, or hardened glass coatings.

Tailored Backlighting: Adjusting brightness (nits), color temperature, and integrating long-life LEDs for specific environments.

Custom Interfaces: Designing boards with specific interfaces (LVDS, eDP, MIPI) to seamlessly connect with a client's mainboard.

A manufacturer that offers these services, as Chuanhang Display does, acts as a solutions provider, helping engineers overcome design challenges and add significant value to the final product.

Electronics manufacturing is vulnerable to supply chain disruptions, as witnessed in recent global events. A reliable LCD manufacturer must demonstrate a robust and resilient supply chain. This involves strategic sourcing of key components like driver ICs, glass, and LED backlights from multiple reputable suppliers to mitigate shortages.

Furthermore, product longevity is crucial for businesses that plan to market a product for many years. A strong LCD manufacturer guarantees long-term product support, including a commitment to not discontinuing a core display module without ample notice (often a year or more) and providing a Last-Time-Buy (LTB) option. This prevents clients from being forced into costly and time-consuming redesigns mid-product lifecycle.

Even after selecting a qualified LCD manufacturer, integrators can face several common issues.

Screen Artifacts: This includes dead or stuck pixels, backlight uniformity issues (hotspots), and image persistence or burn-in. While manufacturers have pixel defect policies (e.g., ISO 13406-2 Class), clarifying these standards upfront is essential.

Electromagnetic Interference (EMI): LCDs can be both sources of and susceptible to EMI. A good manufacturer will provide EMI test reports and offer shielded designs to ensure compliance with FCC/CE regulations.

Compatibility and Interface Mismatch: A common pitfall is the mismatch between the LCD's interface (e.g., LVDS signal voltage) and the host system's controller. Detailed datasheets and technical support from the manufacturer are vital to avoid this.

Touchscreen Integration Issues: When integrating a resistive or capacitive touch panel, problems with calibration, sensitivity, or noise can arise. Working with a manufacturer that provides fully integrated touch solutions can alleviate these problems.

Environmental Reliability: Displays used in extreme temperatures, high humidity, or shock/vibration environments may fail if not specified correctly. Ensuring the LCD manufacturer tests for and guarantees performance under specific environmental conditions is critical.

In a crowded market, distinguishing a true partner from a simple supplier is key. A manufacturer like Chuanhang Display exemplifies the shift from a component vendor to an integrated solutions partner. They engage early in the design process, offering expert advice on technology selection, helping optimize the design for manufacturability and cost, and providing robust after-sales support. This collaborative approach de-risks product development and accelerates time-to-market for their clients, solidifying their role as a trusted LCD manufacturer.

Selecting an LCD manufacturer is a strategic decision with long-lasting implications. It requires a careful evaluation of their technological expertise, quality systems, customization capabilities, and supply chain strength. By understanding the common technical issues and prioritizing a manufacturer that offers proactive support and transparency, businesses can secure a reliable source of high-quality displays that will ensure the success and longevity of their products in the market. Partnering with an established and service-oriented company provides not just a component, but a critical piece of your product's identity and user experience.