If you’ve ever wondered how the vibrant display on your smartphone, TV, or dashboard comes to life, the answer lies within the sophisticated world of an LCD factory. These manufacturing hubs are where innovation meets precision engineering, turning raw materials into the high-resolution screens we rely on daily. In this article, we take you behind the scenes to explore how an LCD factory operates, the technology involved, and common issues that arise during production and use. We’ll also highlight how brands like Chuanhang Display maintain quality in a competitive market.

An LCD factory is a specialized manufacturing facility designed for the production of liquid crystal display (LCD) panels. These factories are often massive, cleanroom environments where temperature, humidity, and particulate matter are strictly controlled. Even a speck of dust can ruin a display, so the entire process occurs in highly sterile conditions.

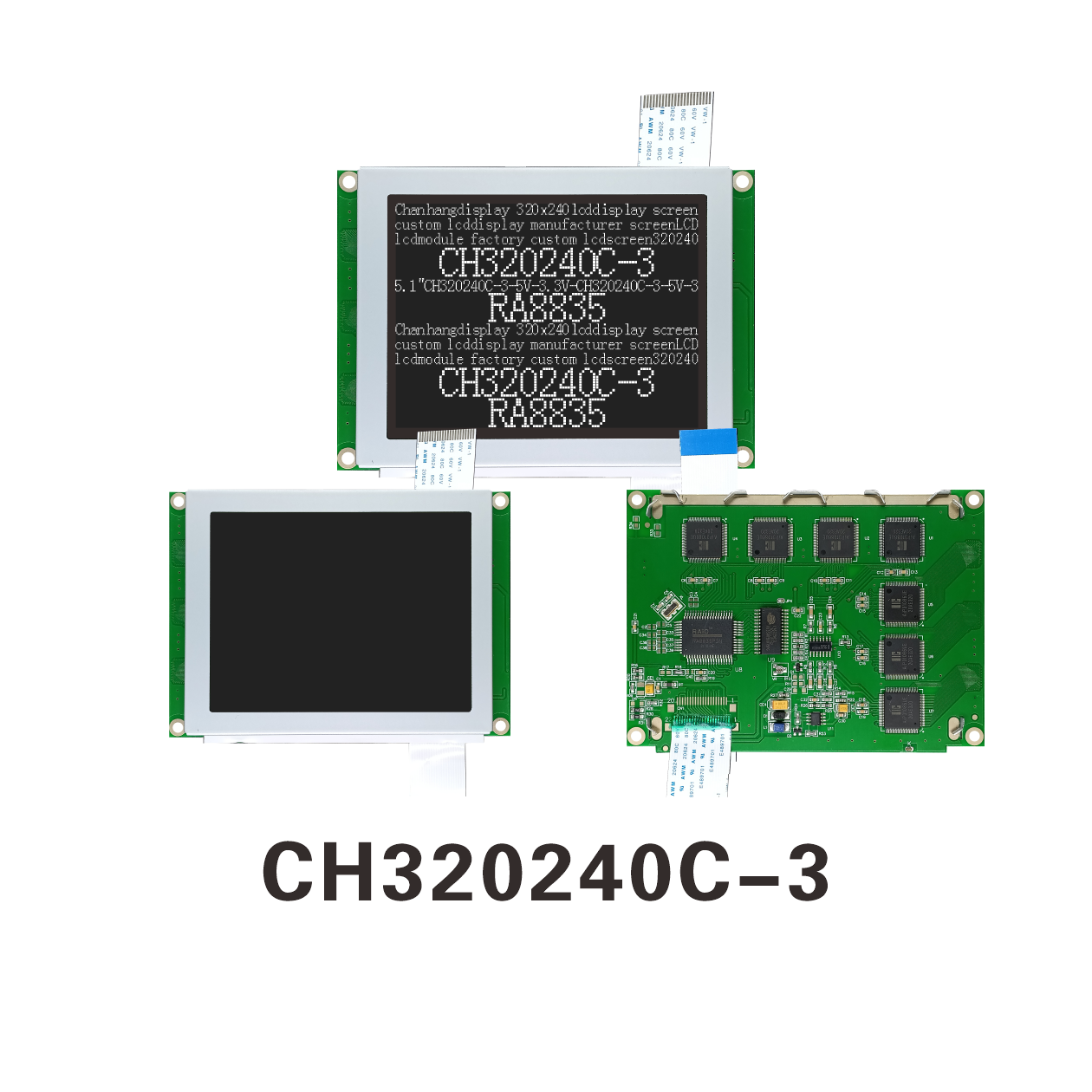

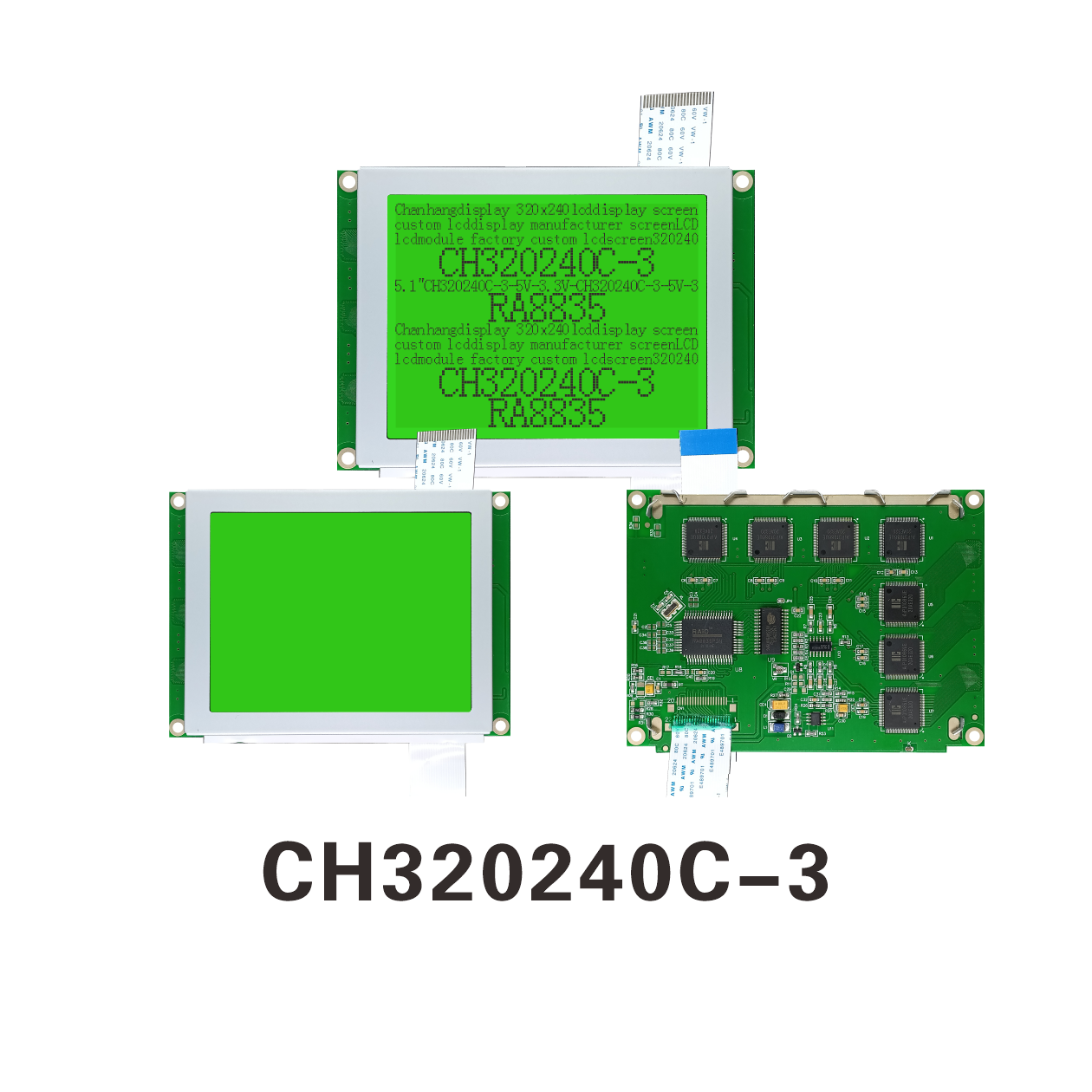

The core function of an LCD factory is to transform glass substrates into functional LCD panels through a series of complex steps including photolithography, etching, alignment, and assembly. Companies like Chuanhang Display operate state-of-the-art factories that integrate automation and rigorous testing to produce everything from small industrial screens to large-format television panels.

The creation of an LCD panel is a multi-stage process that requires extreme precision. Here’s a simplified breakdown of how most LCD factories operate:

Array Manufacturing: This initial phase involves creating thin-film transistors (TFTs) on a glass substrate. Photolithography is used to imprint circuit patterns, similar to how semiconductors are made. This forms the backbone that will control each individual pixel.

Cell Assembly: In this step, two glass substrates (one with TFTs and another with a color filter) are aligned and assembled with a precise gap between them. Liquid crystal material is injected into this gap, and the layers are sealed.

Module Assembly: Here, the LCD cell is combined with other components like the backlight unit, polarizers, driver ICs, and flexible printed circuits. The backlight provides the light source, while the drivers control the pixels.

Testing and Quality Assurance: Each module undergoes rigorous testing for defects such as dead pixels, uneven backlighting, or color shifts. Brands like Chuanhang Display use automated optical inspection (AOI) systems to ensure consistency.

This entire process requires advanced machinery and meticulous attention to detail. Even a minor error can lead to noticeable defects in the final product.

LCDs are used in a wide range of applications, and the requirements for each can vary significantly. An LCD factory often produces customized displays based on the client’s needs.

Consumer Electronics: Smartphones, tablets, laptops, and televisions.

Industrial Equipment: Human-machine interfaces (HMIs), medical devices, and diagnostic screens.

Automotive Displays: Digital dashboards, infotainment systems, and rear-seat entertainment.

Specialized Displays: Outdoor kiosks, aviation, and military equipment.

Chuanhang Display, for example, provides tailored solutions for industries requiring high brightness, wide temperature ranges, or enhanced durability.

Despite advancements in technology, LCD production and performance are not without challenges. Here are some frequent issues encountered:

1. Dead or Stuck Pixels

A common problem where pixels remain black (dead) or a single color (stuck). This often occurs due to impurities during manufacturing or transistor failure. Most LCD factory standards allow a limited number of pixel defects based on industry norms (e.g., ISO 13406-2).

2. Backlight Bleeding

This refers to uneven light distribution from the edges of the screen, resulting in patches of non-uniform brightness. It is usually caused by improper assembly or pressure on the panel.

3. Image Persistence (Burn-in)

Though more common in OLEDs, LCDs can also suffer from temporary image retention, especially under prolonged static display. This is often due to prolonged DC voltage application to the liquid crystals.

4. Mura Defects

Mura is a Japanese term for unevenness. It appears as cloud-like shadows or color shifts across the screen and is typically caused by variations in cell gap thickness or impurities in the LC layer.

5. Touchscreen Malfunctions

For touch-enabled LCDs, issues like unresponsive areas or ghost touches can arise from sensor misalignment, electrical interference, or physical damage.

Reputable manufacturers like Chuanhang Display implement strict quality control protocols to minimize these defects, but some issues may still emerge over time or under extreme conditions.

Chuanhang Display is an established LCD manufacturer known for investing in advanced LCD factory facilities. Their approach to quality includes:

Automated Inspection Systems: Using machine vision to detect microscopic defects.

Environmental Stress Testing: Panels are tested under various temperatures, humidity levels, and voltages.

Customization and Support: Offering tailored solutions and technical support to address specific application needs.

Their focus on R&D and customer collaboration helps mitigate common LCD problems before products reach the market.

While newer technologies like OLED and MicroLED gain attention, LCD remains dominant due to its cost-effectiveness and improving quality. Modern LCD factory lines are adopting technologies like Mini-LED backlighting and high refresh rate support to stay competitive.

Innovations in materials and manufacturing efficiency will continue to drive the evolution of LCDs. Companies like Chuanhang Display are at the forefront of integrating these new technologies to meet future demands.

An LCD factory is a marvel of modern engineering, combining cleanroom precision, chemical processes, and electronic integration to produce the displays we use every day. While challenges like dead pixels or backlight bleeding can occur, continuous improvements in manufacturing and quality control—exemplified by manufacturers like Chuanhang Display—are enhancing reliability and performance.

Whether you're a tech enthusiast, industry professional, or simply curious about how your devices are made, understanding the world inside an LCD factory offers valuable insight into the complexity behind today’s digital displays.