Finding the right partner for your liquid crystal display needs is a critical decision. It impacts product quality, cost, and time to market. The search for a capable LCD manufacturer often starts online, but the results can be overwhelming. This article cuts through the noise. We will outline the key factors to consider and explain how a specialist like Chuanhang Display operates within the global supply chain.

The relationship with your display provider is long-term. Displays are a core user interface component. Their performance, reliability, and delivery consistency can define your product's success. Not every factory is the same. Capabilities, expertise, and customer service levels vary widely across the industry.

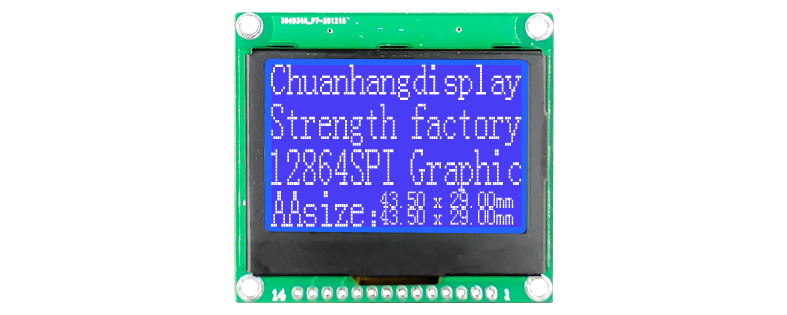

Your project's requirements should guide your search. Start with the basic specifications. Do you need a monochrome character display, a graphical LCD like a 12864 module, or a full-color TFT? Define the size, resolution, interface, and operating temperature range early.

Volume is another primary filter. Some suppliers excel at prototyping and low-volume batches. Others are geared for mass production runs in the hundreds of thousands. Be clear about your projected needs to find a partner that can scale with you.

Technical support is non-negotiable. A good LCD manufacturer will have engineers who can understand your schematic and suggest optimizations. They should provide comprehensive documentation, including detailed datasheets and initialization codes for their modules.

True capability goes beyond assembly. A manufacturer with strong in-house engineering can be a valuable design partner. At Chuanhang Display, the engineering team works directly with clients from the concept phase.

This collaboration can involve customizing the glass (LCD cell) for unique shapes or pixel layouts. It also includes designing the printed circuit board (PCB) that drives the display. Having this expertise under one roof prevents communication gaps and accelerates development.

Such a manufacturer can often integrate additional components. This includes touch panels (resistive or capacitive), backlight drivers, or even full system-on-chip solutions. This turns a simple display module into a complete sub-assembly, saving you integration time.

Consistent quality separates reputable suppliers from the rest. Ask about the quality management system. International standards like ISO 9001 are a good baseline. For specific industries, other certifications may be required.

Inspection happens at multiple stages. Incoming materials, like the glass and polarizers, are checked. During production, automated optical inspection (AOI) machines scan for pixel defects or bonding issues. A final aging test, where modules are powered under temperature stress, is common for reliable producers.

Chuanhang Display maintains a rigorous QC protocol. Each batch undergoes sampling against agreed-upon quality standards. This systematic approach minimizes the risk of field failures and ensures every shipment meets expectations.

The global electronics market is vulnerable to shortages. A manufacturer's sourcing network and strategic inventory are crucial for stability. Long-term relationships with raw material suppliers provide some insulation from market volatility.

A vertically integrated LCD manufacturer has more control. If they produce their own LCD cells or source them from trusted, tier-one glass suppliers, the risk is lower. They should also maintain a safety stock of key components, like driver ICs and LED backlights, for ongoing projects.

Transparency about lead times is essential. A professional partner will provide realistic timelines and communicate proactively about any potential delays. This allows you to plan your own production schedule with confidence.

Effective communication is the glue that holds a project together. Your point of contact should be responsive and technically competent. They must bridge the gap between your needs and the factory floor.

Look for a supplier that assigns a dedicated project manager or account engineer. This person coordinates samples, provides updates, and handles any technical queries. Time zone alignment and language capability are practical considerations for smooth collaboration.

Chuanhang Display structures its client services around this principle. From the first inquiry to post-delivery support, a single point of contact guides the process. This simplifies management and builds a stronger partnership.

Many electronic manufacturers offer displays as a side product. A dedicated LCD manufacturer focuses all its resources on this technology. This deep focus results in better expertise, more refined processes, and a more reliable product.

Specialists are more likely to invest in advanced equipment for cutting, bonding, and testing. They follow industry trends in new interfaces, higher resolutions, and energy-efficient backlighting. Their entire business is built on solving display-related challenges.

Choosing a specialist like Chuanhang Display means accessing this depth of knowledge. Their team encounters a wide array of applications, from industrial HMIs to medical devices. This experience directly benefits your project.

Your choice of display supplier should be viewed as a strategic partnership. The right manufacturer becomes an extension of your own engineering team. They contribute to solving problems and optimizing your product's design.

A successful partnership evolves. It can start with a standard product, move to a customized version, and eventually lead to a fully bespoke solution. This journey requires trust, clear communication, and mutual commitment to quality.

Working with a professional LCD manufacturer streamlines your operations. It reduces qualification time for new components and mitigates supply risk. In the competitive electronics landscape, this reliable foundation is a significant advantage. Companies like Chuanhang Display exist to provide exactly this stability and expertise, ensuring your product vision is realized with a clear, reliable interface.

Q1: What is the typical minimum order quantity (MOQ) for a custom LCD module?

A1: MOQs vary significantly. For a standard module, it can be as low as 100-500 pieces. For a fully custom design involving new glass masks, the MOQ will be higher, often starting from 10,000 pieces, to amortize the high initial tooling costs.

Q2: Can you help us integrate a touchscreen with the display?

A2: Yes, most experienced manufacturers offer this service. Both resistive and capacitive touch panels can be optically bonded to the LCD surface. This creates a streamlined, durable touch display module ready for installation in your product.

Q3: How long does the development process take for a customized display?

A3: A timeline depends on complexity. A modification of an existing module (like changing the FPC connector) may take 4-6 weeks for samples. A completely new design, requiring new glass tooling, can take 12-16 weeks or more from design freeze to first samples.

Q4: What file formats do you need from us to start a custom design?

A4: Manufacturers typically need a detailed specification sheet, a desired mechanical outline drawing (in DXF or DWG format), and a pinout definition. For the graphic design, they often need a pixel-accurate image file showing the desired icons and layout.

Q5: Do you provide displays that can operate in extreme temperatures?

A5: Specialized manufacturers offer extended temperature range options. Standard industrial modules often operate from -20°C to +70°C. For automotive or outdoor applications, versions can be sourced or developed to function from -40°C to +85°C or higher, using specific liquid crystal mixes and components.