The display interface is the face of your product. Whether you are engineering a handheld medical device, an automotive dashboard, or an industrial control panel, the component that users interact with most is the display. In the current electronics market, the TFT LCD screen remains the dominant standard for reliability and cost-effectiveness.

While newer technologies like OLED grab headlines for smartphones, the Thin Film Transistor (TFT) Liquid Crystal Display continues to hold the majority market share in industrial and commercial sectors. This is due to its proven longevity, stable supply chain, and high brightness capabilities.

Finding the right module is not just about resolution. It involves balancing power consumption, viewing angles, and production costs. At Chuanhang Display, we see daily how specific project requirements dictate the choice of panel materials and backlight structures. This article breaks down the technical and commercial realities of sourcing these screens in 2025.

To make an informed purchase, you must understand what happens inside the module. A standard TFT LCD screen is an active-matrix display. This means every pixel is controlled by one to four transistors. This technology allows for much faster response times and better color retention compared to older passive-matrix displays.

The structure is a sandwich of complex layers. It starts with the backlight unit (BLU), followed by the rear polarizer, the TFT glass substrate, the liquid crystal layer, the color filter glass, and finally, the front polarizer.

The "TFT" part is crucial. Because each pixel has its own transistor, the electrical current can be kept low while maintaining high switching speeds. This results in sharp images and smooth motion video, which is essential for modern user interfaces.

Not all TFTs are built the same. When sourcing a TFT LCD screen, you will generally choose between three main panel technologies.

TN (Twisted Nematic) is the oldest and most cost-effective. It offers the fastest response times, which is why gamers used to prefer it. However, the viewing angles are poor. If you look at a TN screen from the side, the colors invert.

IPS (In-Plane Switching) is the current industry standard for premium devices. It offers excellent color reproduction and very wide viewing angles (usually 178 degrees). For a medical device or a high-end kiosk, IPS is usually the mandatory choice.

VA (Vertical Alignment) sits in the middle. It offers better contrast ratios than IPS, resulting in deeper blacks, but the viewing angles are slightly narrower.

When you look at a datasheet from a supplier like Chuanhang Display, there are three specific lines you need to scrutinize beyond just the resolution.

1. Brightness (Nits)A standard laptop screen is about 250 nits. This is fine for an office. However, if your device is used outdoors or under bright factory lights, you need a high-brightness TFT LCD screen. We recommend a minimum of 800 to 1000 nits for any outdoor application to ensure sunlight readability.

2. Temperature RangeConsumer electronics usually operate between 0°C and 50°C. Industrial applications are different. A screen in a vehicle or an outdoor charging station must withstand wide temperature swings. You should look for "Wide Temperature" panels that operate from -30°C to +80°C without the liquid crystals freezing or boiling (turning black).

3. Interface TypesHow does your motherboard talk to the screen?

MCU/SPI: Used for small, low-resolution screens. Simple to code but slow.RGB: Good for medium-sized screens without high-speed data needs.LVDS: The standard for larger screens (7 inches to 15 inches). It resists noise well.MIPI: Common in high-resolution, small screens (like smartphones).eDP: Used in high-resolution, larger panels (laptops and monitors).

Pricing is often the biggest friction point in procurement. Why does one 5-inch screen cost $15 while another costs $45? The price of a TFT LCD screen is driven by yield rates, customization, and raw materials.

Glass Substrate AvailabilityThe LCD industry moves in cycles. The large glass sheets (Mother Glass) are cut into smaller panels. If the market demand for 55-inch TV panels is high, manufacturers optimize their cuts for TVs, causing a shortage of smaller industrial sizes. This fluctuation affects unit price.

Backlight CustomizationThe backlight unit contributes significantly to the cost. Increasing brightness from 300 nits to 1000 nits requires more efficient LEDs and better heat dissipation films. This increases the Bill of Materials (BOM) cost.

NRE Fees (Non-Recurring Engineering)If you need a custom Flexible Printed Circuit (FPC) to fit your housing, or a custom touch panel shape, suppliers will charge an NRE fee. This is a one-time setup cost for tooling. Chuanhang Display often works with clients to optimize these designs to keep NRE costs manageable.

Once you have selected the display, you often need to attach a touch panel or a protective cover glass. The method of attachment affects optical performance and durability.

Air Bonding (Tape Bonding)This is the cheaper method. Double-sided adhesive tape attaches the touch panel to the TFT LCD screen bezel. There is a small air gap between the glass and the LCD.

Pros: Low cost, easy to repair.Cons: The air gap causes internal reflection, making the screen look washed out in sunlight. Dust can eventually get inside.

Optical Bonding (OCA/OCR)This involves filling the gap between the LCD and the cover glass with a transparent resin or adhesive.

Pros: Eliminates internal reflection, increasing perceived brightness and contrast. It also improves durability against impact.Cons: Higher manufacturing cost and difficult to rework if a defect occurs.

For premium industrial or outdoor products, optical bonding is highly recommended.

The supply chain for displays is vast, primarily centered in East Asia. Finding a vendor is easy; finding a partner is hard. A reliable TFT LCD screen supplier must offer continuity.

Longevity (EOL Management)In the consumer market, screens change every six months. In the industrial sector, a medical device might be sold for ten years. You cannot afford for your screen to go End-of-Life (EOL) next year. You need a supplier who guarantees availability for 3 to 5 years or offers pin-to-pin compatible replacements.

Quality Control StandardsAsk your supplier about their pixel fault policy. ISO standards allow for a certain number of dead pixels. For high-end applications, you must specify "Zero Dead Pixel" requirements in your contract.

At Chuanhang Display, we focus on matching the specific grade of the panel to the client's budget and quality needs. We ensure that the FPC design and interface logic remain consistent even if the raw glass supplier updates their generation lines.

Modern user interfaces rarely use just a display; they use a touch display.

Resistive Touch is the older pressure-based tech. It works with gloves and is cheap, but it reduces screen brightness and supports only single-touch.

Capacitive Touch (PCAP) is what smartphones use. It supports multi-touch and gestures. However, in industrial settings, water droplets or thick industrial gloves can confuse capacitive sensors.

When ordering a TFT LCD screen with touch, you must specify the controller IC tuning. For example, if your device will be used in the rain, the touch controller firmware needs to be tuned for "water rejection" to prevent phantom touches.

The technology behind the TFT LCD screen is mature, but it is not stagnant. We are seeing a shift toward higher pixel densities (PPI) in smaller industrial screens. Users accustomed to "Retina" displays on phones now expect the same sharpness on their coffee machine interface.

Another trend is power efficiency. New liquid crystal materials and more efficient LED backlights are allowing screens to run longer on battery power. This is critical for handheld scanners and portable medical equipment.

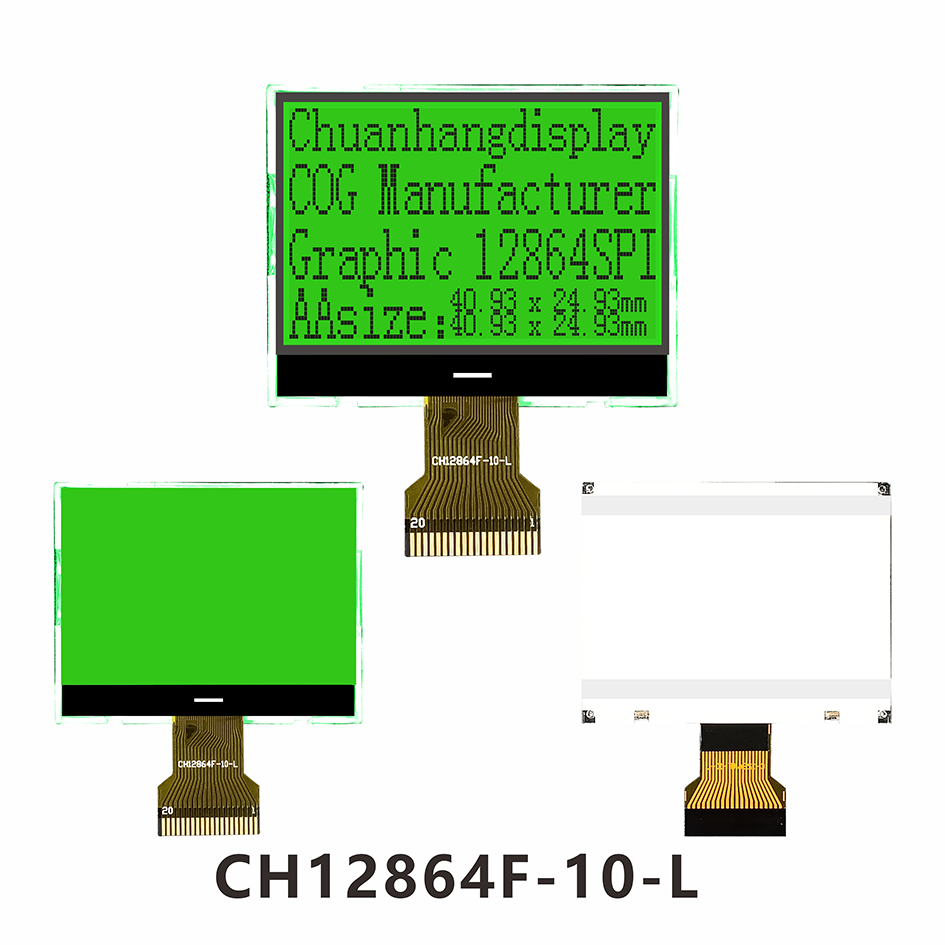

Furthermore, the integration of driver ICs is becoming more streamlined. Chip-on-Glass (COG) technology is reducing the physical footprint of the module, allowing for thinner bezels and more compact device designs.

Selecting the correct display module is a balance of specification, environment, and budget. It requires looking beyond the brochure and understanding the manufacturing process. From the viewing angles of IPS technology to the bonding method used for the cover glass, every detail impacts the user experience.

The market is flooded with options, but quality varies drastically. A cheap screen often ends up costing more in returns and engineering fixes. Whether you need a high-brightness solution for an outdoor kiosk or a stable supply for a medical instrument, the TFT LCD screen remains the reliable choice for 2025.

For businesses looking for consistent quality and technical support that understands the nuances of industrial integration, Chuanhang Display is ready to assist. We bridge the gap between complex component manufacturing and your finished product needs.

Q1: What is the typical lifespan of a TFT LCD screen in an industrial setting?

A1: The lifespan is usually determined by the backlight LEDs, not the liquid crystals. A standard industrial TFT LCD typically offers a backlight half-life of 30,000 to 50,000 hours. This means the screen will be half as bright as it was when new after that period. Running the screen at lower brightness levels can significantly extend this lifespan.

Q2: Can I use a consumer-grade TFT LCD screen for an outdoor application?

A2: It is not recommended. Consumer screens usually have low brightness (200-300 nits) which makes them unreadable in sunlight. Furthermore, the UV radiation from the sun can yellow the consumer-grade polarizers and the isotropic glue, causing the screen to fail prematurely. You need a high-brightness panel with anti-UV surface treatment.

Q3: What is the difference between TTL and LVDS interfaces on a TFT LCD?

A3: TTL (Transistor-Transistor Logic) is typically used for smaller, lower-resolution screens and sends data in parallel, which requires many wires and is susceptible to interference over long distances. LVDS (Low-Voltage Differential Signaling) sends data serially at high speeds using lower voltage, allowing for longer cables and better noise immunity, making it standard for larger HD screens.

Q4: Why does my TFT LCD screen look black when I wear polarized sunglasses?

A4: This happens due to the polarization angle. The light coming out of an LCD is polarized. If the angle of the polarized light from the screen is perpendicular to the polarization of your sunglasses, the light is blocked, and the screen looks black. Chuanhang Display can use a circular polarizer or specific retardation films to fix this issue for outdoor devices.

Q5: What is the "Ghosting" effect on a TFT LCD screen?

A5: Ghosting occurs when the response time of the pixels is too slow to keep up with rapidly moving images. The previous image frame remains visible for a split second while the new one loads, creating a blur. This is less common in modern active-matrix TFTs but can still happen in very cold temperatures if the liquid crystal fluid becomes viscous. Wide-temperature panels solve this.