For decades, engineers and product designers have relied on specific display technologies that offer reliability, low power consumption, and clarity. While colorful touchscreens dominate consumer electronics, the 7 Segment LCD remains the preferred choice for industrial instrumentation, medical devices, and utility meters. Its simplicity is its strength, yet designing a custom panel requires deep knowledge of optical modes, drive methods, and manufacturing constraints.

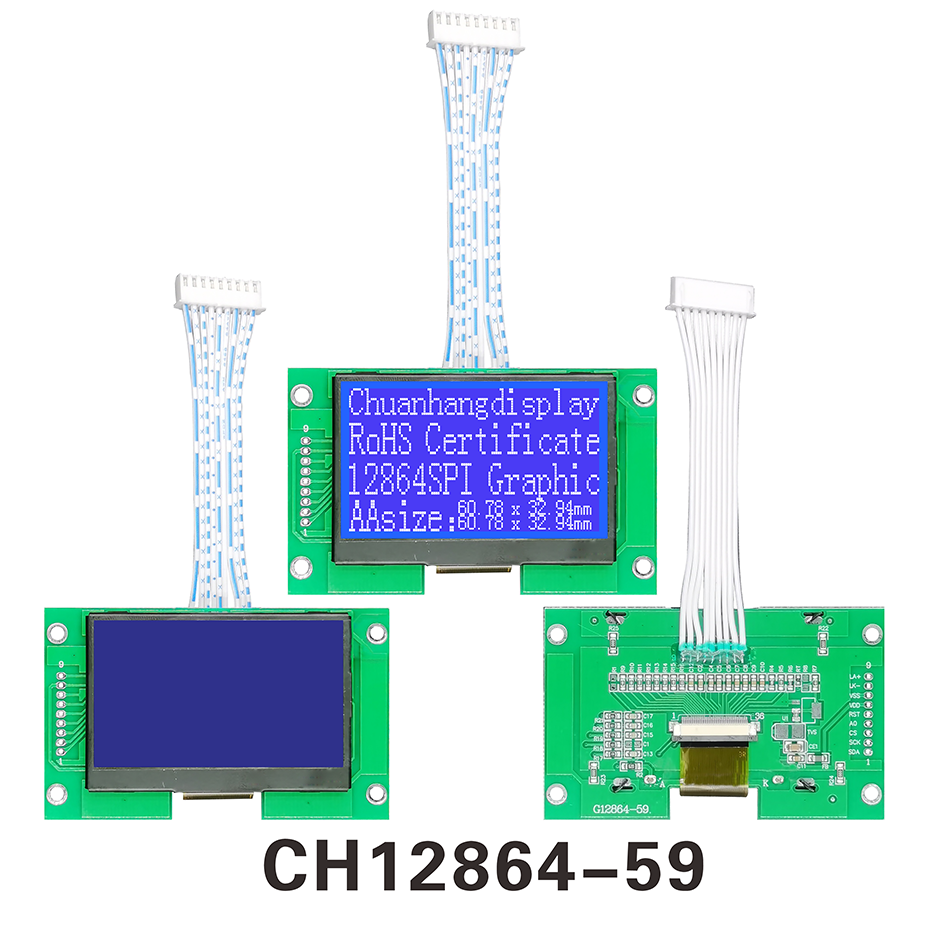

At Chuanhang Display, we see a consistent demand for these robust screens. They function in extreme temperatures where TFTs might fail, and they run for years on a single coin-cell battery. This article breaks down the technical specifications, customization options, and commercial considerations for sourcing high-quality segment liquid crystal displays.

A segment display operates on a straightforward principle: controlling light passage through liquid crystals aligned between two layers of glass. Unlike dot-matrix screens that require complex controllers to render graphics, a 7 Segment LCD uses pre-defined patterns—specifically the number "8" formed by seven segments, plus a decimal point.

The glass substrate is coated with a transparent conductive layer, typically Indium Tin Oxide (ITO). When voltage applies to a specific segment, the liquid crystal molecules reorient. This change affects the polarization of light passing through, making the segment appear dark (positive mode) or clear (negative mode) against the background.

Product developers favor this technology because it places a minimal load on the system’s microcontroller (MCU). Driving these segments requires very little processing power, leaving the MCU free to handle critical sensor data or measurement tasks.

When selecting a 7 Segment LCD, you must define how the segments are driven. This decision impacts the pin count of the glass and the complexity of your circuit board.

In a static drive configuration, every segment has a dedicated connection to the driver. If you have a display with four digits, that requires a significant number of pins. However, static drive offers the best contrast and the widest viewing angles. It is often used in high-precision measurement tools where readability from acute angles is mandatory.

To reduce pin count, manufacturers use multiplexing. Here, segments share electrical connections and are driven rapidly in sequence.

Duty Cycle: This represents the fraction of time a segment is energized during one cycle. Common ratios are 1/3 or 1/4 duty.Bias: This defines the voltage levels used to keep non-selected segments off while selected ones turn on.

Higher multiplexing rates reduce the number of pins required on the 7 Segment LCD, lowering hardware costs. However, pushing the multiplexing too high can degrade contrast and reduce the viewing cone. Balancing pin count against optical performance is a key design step.

Not all segment displays look the same. The fluid type inside the glass determines the contrast, color, and viewing angle.

Twisted Nematic (TN)TN is the most cost-effective option. It provides a black segment on a gray background (or vice versa). It works well for budget-sensitive projects like water meters or basic timers. The viewing angle is somewhat limited, usually defined as 6:00 or 12:00 direction.

Super Twisted Nematic (STN)For applications requiring a wider viewing angle, STN is the upgrade. It twists the light more aggressively, resulting in sharper contrast. STN 7 Segment LCD panels often have a characteristic yellow-green or blue background. They are standard in industrial controllers.

Vertical Alignment (VA)VA represents the premium tier of segment technology. It offers a true black background with extremely high-contrast colored segments. This "black mask" look mimics the aesthetics of OLED but retains the longevity and lower cost of an LCD. Automotive dashboards and high-end audio equipment frequently utilize VA segment displays for their sleek appearance.

How the glass connects to your PCB is just as important as the glass itself. The reliability of the final product often hinges on this interface.

Metal Pins: Sturdy and soldered directly into the PCB. This is excellent for environments with high vibration, such as automotive or heavy machinery.Zebra Strips (Elastomeric Connectors): A rubber strip with conductive layers sits between the glass and the PCB. A bezel compresses the stack. This allows for easy assembly and disassembly but requires precise mechanical design.Heat Seal / FPC: A flexible ribbon cable is bonded to the glass. This is ideal when the 7 Segment LCD cannot be mounted directly on the main board due to space constraints.

Off-the-shelf displays rarely fit the specific needs of a new product perfectly. A generic screen might have a battery icon, but your device might need a "WiFi" symbol or a specific measurement unit like "psi" or "°C".

Custom tooling allows you to define every element of the screen. At Chuanhang Display, we assist clients in designing custom ITO patterns. This means you can place icons exactly where your UI requires them. You are not limited to standard digits; you can incorporate 14-segment "starburst" digits for better alphanumeric capability or custom gauges that fill up as values increase.

The customization process also involves selecting the polarizer type:

Reflective: Uses ambient light only. Extremely low power, perfect for well-lit areas.Transflective: Reflects ambient light but allows a backlight to pass through. Readable in both sunlight and darkness.Transmissive: Requires a backlight at all times. Best for negative mode displays (light text on dark background).

A raw 7 Segment LCD does not emit light; it modulates it. For devices used in low-light conditions, a backlight unit (BLU) is essential. LED arrays are the industry standard for this.

Side-lit LED backlights are thin and cost-effective, using a light guide plate to diffuse illumination across the screen. Bottom-lit arrays offer higher brightness but add thickness to the module.

Power management becomes a calculation of the backlight current rather than the LCD drive current. While the 7 Segment LCD consumes microamps, the backlight might consume 10 to 20 milliamps. Engineers often design circuits to pulse the backlight or dim it based on ambient light sensors to conserve battery life in portable devices.

One misconception is that custom displays are prohibitively expensive. In reality, the Non-Recurring Engineering (NRE) fee—the cost to create the tooling masks—for a 7 Segment LCD is relatively low compared to TFTs or OLEDs.

For a standard TN panel, tooling fees are often a few hundred to a thousand dollars, depending on size. Once the tool is made, the unit price drops significantly. This economic model favors volume production. A custom glass panel can cost less than a dollar in high quantities, making it arguably the most economical display technology available.

Factors that increase cost include:

Extended Temperature Fluids: For outdoor use (-30°C to +80°C).Custom Color Printing: Silk-screening colors onto the background for fixed warnings or logos.High-End Polarizers: Using specialized films for sunlight readability or sunglass compatibility.

Reliability is the hallmark of this technology. A well-manufactured 7 Segment LCD can operate for 10 to 20 years without significant degradation. The primary failure modes usually involve the connector (zebra strip misalignment) or the backlight LEDs fading over time, rather than the liquid crystal itself failing.

Manufacturers perform rigorous testing, including thermal shock cycles and high-humidity storage tests. Because these displays are often used in utility meters (gas, water, electric) which are sealed units deployed for decades, the degradation of the polarizer adhesive is a critical quality metric we monitor.

Despite the surge of high-res screens, the market for segment displays is growing in specific sectors.

Medical DevicesBlood pressure monitors, glucose meters, and digital thermometers require absolute clarity. A confusing display can lead to medical errors. The sharp, high-contrast digits of a segment screen leave no room for ambiguity.

E-Mobility and AutomotiveElectric bicycles and scooters use 7 Segment LCD dashboards to show speed and battery life. They are readable in direct sunlight—a weakness of many cheap color screens—and they don't drain the vehicle's battery unnecessarily.

Industrial AutomationFactory floors are harsh environments. Panel meters that display voltage, pressure, or RPM needs to be legible from a distance and resistant to electrical noise. The static drive LCD is immune to many of the interference issues that plague complex capacitive touchscreens.

Selecting a manufacturer goes beyond comparing price sheets. Communication regarding the IC driver compatibility and mechanical integration is vital.

Chuanhang Display focuses on bridging the gap between concept and mass production. We understand that a datasheet is not enough; you need advice on whether a 1/4 duty cycle will provide enough contrast for your specific viewing angle requirements. We ensure that the pinout of the custom glass aligns perfectly with your PCB layout to minimize routing complexity.

When evaluating a supplier, ask about their half-life testing for backlights and their capability to handle variable operational temperatures. A supplier that understands the physics of liquid crystals will save you from costly redesigns later in the product lifecycle.

The 7 Segment LCD remains a cornerstone of modern electronics engineering. Its blend of energy efficiency, sunlight readability, and design flexibility makes it irreplaceable for critical data display. Whether you are designing a handheld medical tool or a rugged industrial meter, understanding the nuances of viewing angles, drive modes, and connection types is essential.

By partnering with an experienced manufacturer like Chuanhang Display, you gain access to customization capabilities that turn a generic component into a brand-defining interface. From the initial tooling of the ITO glass to the final integration of the backlight, we support the technical decisions that lead to a successful, long-lasting product.

Q1: What is the main difference between TN and HTN in a 7 Segment LCD?

A1: TN (Twisted Nematic) typically has a twist angle of 90 degrees, offering basic contrast and a lower cost. HTN (High Twisted Nematic) has a twist angle typically between 100 and 120 degrees, which provides a slightly wider viewing angle and better contrast than standard TN, making it a middle-ground option for instrumentation.

Q2: Can I use a 7 Segment LCD in freezing temperatures?

A2: Yes, but you must specify "wide temperature" fluid during the design phase. Standard fluids may become sluggish or freeze around 0°C or -10°C. Wide temperature variants can operate effectively down to -30°C or even -40°C, though the response time for the segments to change state will be slower at the lower limit.

Q3: Why are some segments "ghosting" or appearing faintly when they should be off?

A3: This is usually a crosstalk issue caused by incorrect bias settings or driving voltage (VLCD) that is too high. If the voltage supplied to the 7 Segment LCD exceeds the threshold for the liquid crystal fluid, non-selected segments may partially activate. Adjusting the bias ratio or lowering the drive voltage typically resolves this.

Q4: What is the minimum order quantity (MOQ) for a custom segment display?

A4: MOQs vary by manufacturer, but because custom displays require unique tooling, the industry standard typically starts around 1,000 to 5,000 units per order to amortize the setup costs. At Chuanhang Display, we work with clients to manage pilot runs and scale up to mass production volumes.

Q5: How does a VA (Vertical Alignment) segment display differ from a standard black mask LCD?

A5: Standard black mask displays are often printed colors on a TN panel, which can suffer from light bleed. A VA 7 Segment LCD naturally blocks light in its off state, creating a deeply black background with very little light leakage. This results in a contrast ratio that is significantly higher (often 500:1 or more) compared to standard TN screens.