Finding the right display for a compact, reliable electronic device can be a challenge. Designers often struggle with space constraints, signal integrity, and assembly complexity. One packaging technology consistently provides a solution to these issues: the cog lcd display. This method is fundamental for creating sleek, durable, and high-performance modules.

Chip-On-Glass, or COG, represents a specific way of assembling a liquid crystal display module. It directly influences the product's form factor, reliability, and cost. Understanding this technology is crucial for engineers and procurement specialists across various industries. It enables smarter decisions during the component selection phase.

This article explains the COG LCD technology. We will look at how it works, its benefits, and where it is most effectively used. We will also discuss what to look for in a capable supplier.

The term "COG" stands for Chip-On-Glass. It describes the manufacturing process where the driver integrated circuit (IC) is mounted directly onto the glass substrate of the LCD panel.

This is achieved using a conductive adhesive. The driver IC's tiny bumps are bonded to corresponding contact points on the glass. This creates a direct electrical and physical connection without the need for a traditional flexible printed circuit (FPC) to carry the IC.

The result is a highly integrated panel assembly. The critical control electronics become part of the glass itself. This fundamental difference from other packaging methods leads to several distinct advantages.

It is easy to confuse COG with another acronym: COB, or Chip-On-Board. While both aim for miniaturization, they apply to different parts of the display module.

COG, as discussed, places the driver chip directly on the LCD glass. This reduces the size and component count of the core panel assembly.

COB, on the other hand, typically refers to mounting LED chips directly onto a printed circuit board (PCB). This is commonly used for the display's backlight unit to create a thin, uniform light source.

A single display module can utilize both technologies. A cog lcd display for the panel control, and a COB LED array for the backlight. This combination yields an exceptionally compact and robust module.

Why choose a COG LCD? The benefits are significant for modern product design.

Reduced Module Size and Thickness: Eliminating the separate driver IC package and its connecting FPC saves valuable space. This leads to a thinner profile and a smaller border, or "bezel," around the active display area. It is ideal for handheld and wearable devices.

Enhanced Reliability: Fewer physical connections mean fewer potential points of failure. The direct glass-to-IC bond is robust against vibration and mechanical shock. It also improves resistance to environmental factors like humidity.

Superior Electrical Performance: The shorter electrical paths between the driver IC and the glass electrodes reduce signal noise and cross-talk. This often results in better image clarity and contrast, especially noticeable in high-resolution or fast-updating displays.

Cost-Effective Assembly: The process simplifies the final module assembly for the manufacturer. With the driver already on the glass, the remaining steps are more streamlined. This can lead to lower overall production costs at scale.

The strengths of this technology make it the preferred choice for several demanding market segments.

Portable Medical Devices: Glucose meters, portable monitors, and diagnostic tools benefit from the thin, light, and rugged nature of COG displays. Reliability is non-negotiable in medical settings.

Industrial Handheld Terminals: Barcode scanners, rugged PDAs, and inventory control devices are used in tough environments. The shock-resistant and compact design of a cog lcd display ensures longevity.

Consumer Electronics: Smart home interfaces, fitness trackers, and advanced remote controls use COG to achieve sleek, modern designs with wider viewing areas.

Automotive Clusters: While temperature-stable TFTs are common, monochrome or segment COG LCDs are used in secondary dash displays or control panels where space behind the dashboard is extremely limited.

Home Appliance Panels: Modern washing machines, ovens, and coffee machines feature sophisticated user interfaces. COG modules provide a reliable and space-saving solution for integrated control panels.

Selecting the right module involves more than just opting for COG packaging. Several technical factors must align with your project.

Glass Quality and Type: Standard soda-lime glass is common, but for enhanced durability, consider chemically strengthened glass. For extreme conditions, acrylic or polycarbonate windows might be bonded over the display.

Temperature Range and Storage Conditions: Standard commercial-grade displays operate from about -20°C to +70°C. Industrial or automotive-grade cog lcd display units can withstand ranges from -30°C to +80°C or wider. Confirm your operating and storage requirements.

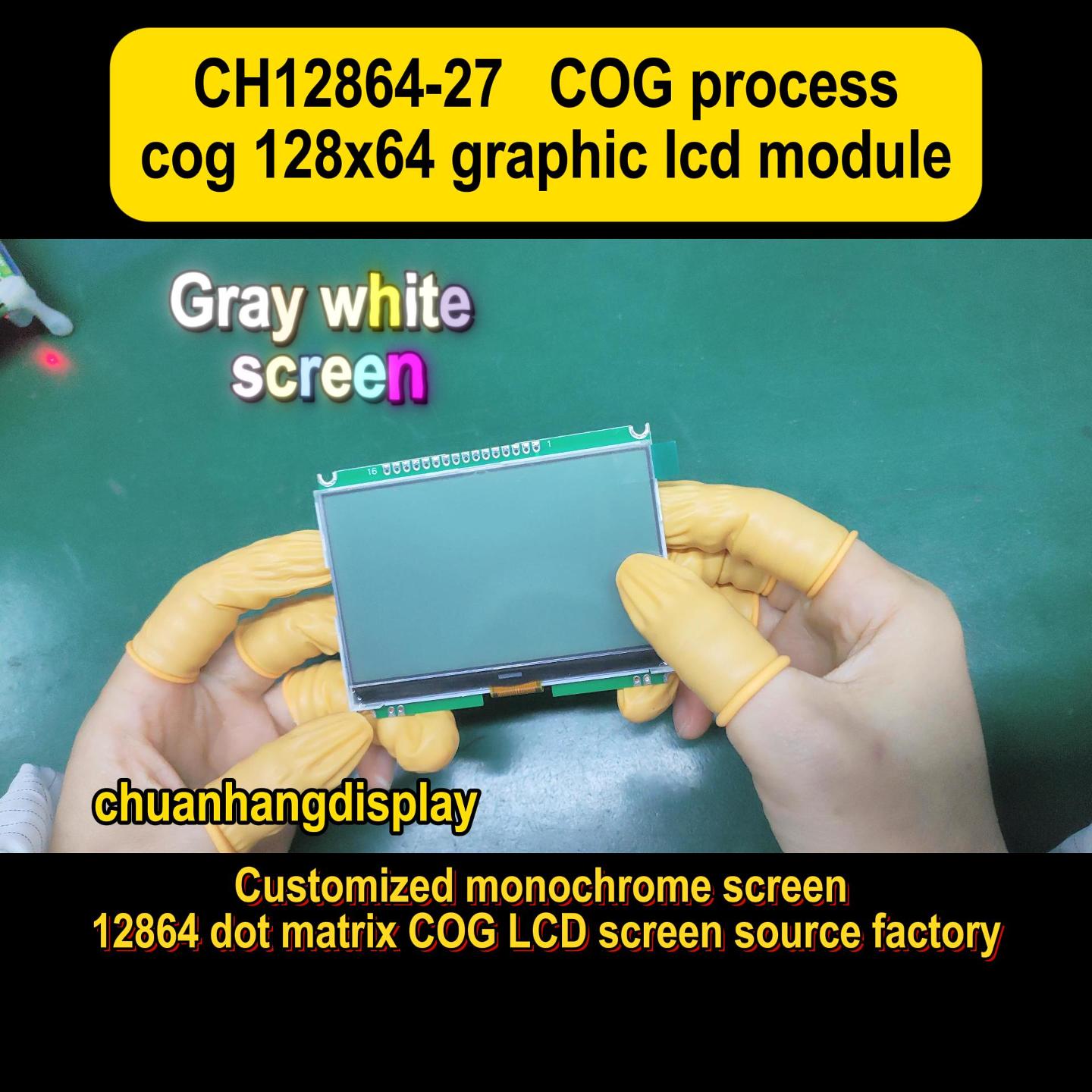

Customization Options: The value of a supplier lies in their ability to tailor the solution. Can they adjust the FPC tail's length and connector type? Can they provide specific anti-glare or anti-fingerprint treatments? Companies like Chuanhang Display specialize in such customizations, adapting standard COG panels to precise application needs.

Optical Bonding Compatibility: For applications exposed to high humidity, condensation, or requiring superior optical performance, optical bonding is key. Ensure your supplier can bond a cover glass or touch sensor directly to the COG panel, filling the air gap with resin.

Not all display suppliers offer deep expertise in COG technology and its customization. Moving from a standard catalog part to an optimized solution requires a technical partner.

A provider like Chuanhang Display focuses on this engineering-led approach. They can guide customers through the specification process. They help select the optimal base glass, driver IC, and connection interface.

Their services extend to applying custom polarizers for improved sunlight readability. They can integrate resistive or capacitive touchscreens seamlessly. They also perform rigorous testing to ensure the final module meets the promised environmental and lifetime specifications.

This level of support transforms a generic cog lcd display into a core, reliable component of your unique product.

The trend in electronics is toward greater integration and miniaturization. COG technology aligns perfectly with this direction.

We can expect driver ICs to become more powerful yet smaller, enabling higher-resolution displays in the same footprint. Integration with touch controller functionality directly into the main driver IC is also evolving.

The partnership between panel fabs and module specialists will remain vital. It bridges the gap between advanced glass technology and the practical, ruggedized modules needed in the field.

The cog lcd display is more than just a type of screen. It is an engineering solution for creating thinner, more reliable, and higher-performance electronic devices. Its advantages in size, durability, and signal integrity make it indispensable across medical, industrial, and consumer applications.

Successful implementation hinges on understanding the technology's nuances and partnering with a knowledgeable supplier. For designers seeking a balance of performance, compactness, and cost, COG remains a compelling and often optimal choice.

Q1: Is a COG display more expensive than a traditional TCP/TAB display?

A1: Initially, the COG panel itself might have a slightly higher unit cost due to the precise bonding process. However, the total system cost is often lower. This is because it simplifies assembly, reduces component count, and improves yield and reliability, saving money in manufacturing and field repairs.

Q2: Can a COG LCD display be repaired if the driver IC fails?

A2: No, this is a key consideration. In a COG module, the driver IC is permanently bonded to the glass. If the IC fails, the entire glass panel must be replaced. This is why reliability and quality control during manufacturing are absolutely critical.

Q3: What are the limitations on resolution for COG technology?

A3: COG is excellent for low to medium-resolution displays (e.g., character, segment, or graphics panels up to roughly QVGA). For very high-resolution TFTs with thousands of connections, the bonding process becomes extremely complex. For high-res TFTs, other packaging like COF (Chip-On-Film) is often preferred.

Q4: How does temperature affect the choice of a COG display?

A4: Temperature dramatically affects the response time and contrast of the liquid crystal. For applications in wide temperature ranges, you must specify an "extended temperature" or "industrial grade" cog lcd display. These use specific LC mixtures and design tolerances to ensure readable performance in cold and hot environments.

Q5: Can touch functionality be added to a COG module?

A5: Yes, absolutely. Resistive (film-glass) or capacitive touchscreens can be laminated onto the front of a COG display. The touch sensor's tail (FPC) is typically routed out alongside the display's own tail. For a fully integrated solution, optical bonding of the touch sensor is recommended to improve optical performance and durability.