Space is the most valuable real estate on any printed circuit board (PCB). As industrial handheld devices, medical monitors, and portable meters shrink in size, the traditional methods of mounting displays are becoming obsolete. The bulky "black blob" of Chip-on-Board (COB) modules simply takes up too much room for modern designs.

This is where the cog lcd display (Chip-on-Glass) architecture has become the standard for compact, high-reliability visualization. For engineers and procurement managers, shifting to COG is not just about saving space; it is about reducing assembly costs and improving signal integrity.

In this report, we analyze the technical architecture of COG technology, compare it against legacy and alternative mounting methods, and discuss how manufacturers like Chuanhang Display are assisting OEMs in integrating these modules into next-generation hardware.

To understand the value of a COG module, we must look at how it differs from traditional assembly. In older LCD technologies, the LCD controller driver (the IC) was mounted on the PCB and connected to the glass via a Zebra strip or a heat-seal connector. This required a large bezel and significant depth.

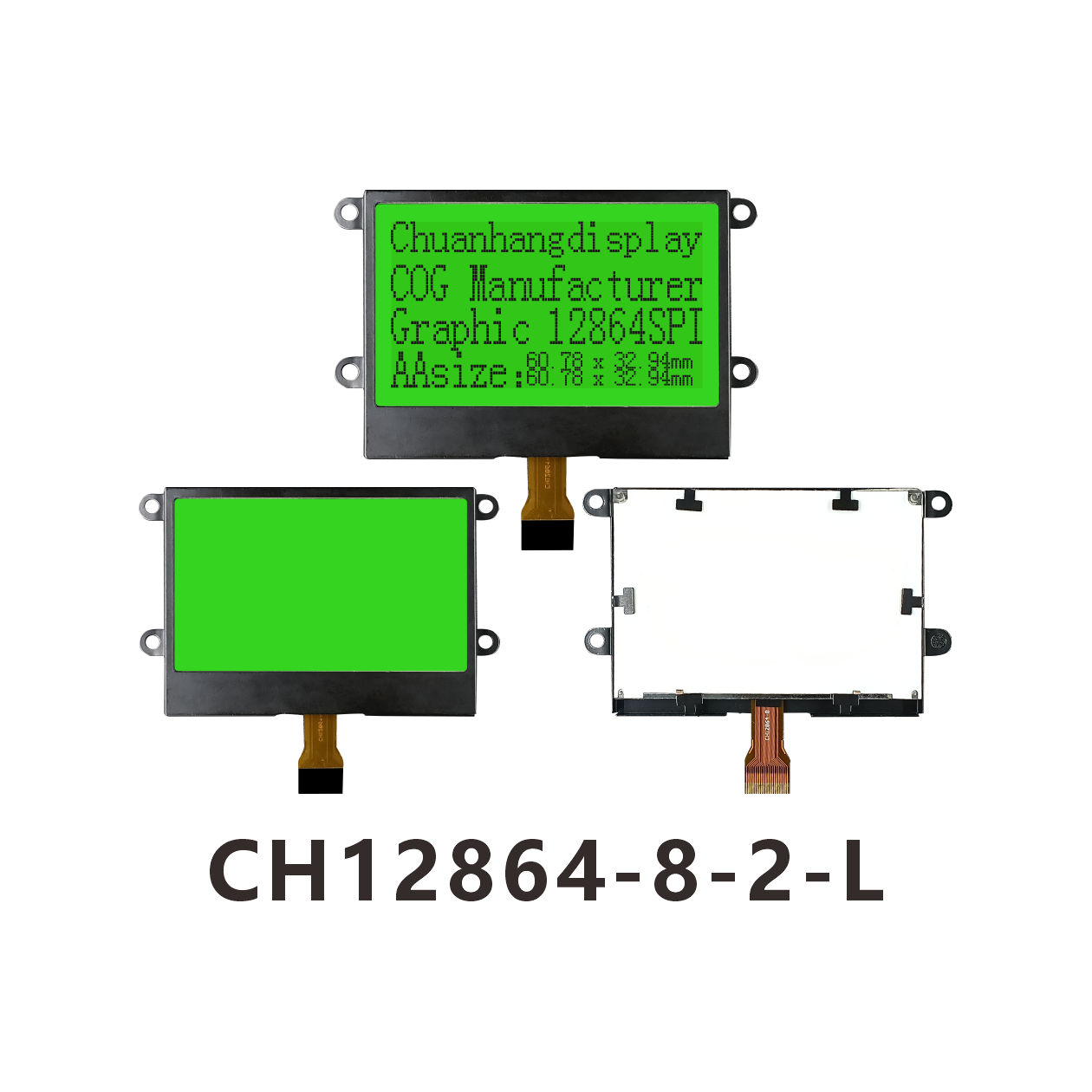

In a cog lcd display, the driver IC is bonded directly onto the overlap edge of the LCD glass itself. There is no need for a separate PCB to hold the chip.

The connection is made using Anisotropic Conductive Film (ACF). This specialized adhesive conducts electricity vertically (connecting the IC bumps to the glass tracks) but insulates horizontally (preventing short circuits between pins). The result is a display module that is essentially just the thickness of the glass plus the backlight, with a very small footprint.

Selecting the right display format is a series of trade-offs. While COG is dominant, it is helpful to understand why you would choose it over the alternatives.

Chip-on-Board was the standard for character displays (like the 16x2 LCDs used in old printers). The IC is wire-bonded to a PCB and covered with a glob of epoxy.

Size: COB is bulky and heavy. COG is thin and light.Cost: COB requires a larger PCB and manual assembly steps. COG is automated and requires fewer external components, often making it cheaper in high volumes.Reliability: COG has fewer solder joints to fail under vibration.

In Chip-on-Flex, the IC is mounted on the flexible cable (FPC) rather than the glass. This is common in high-end OLED smartphones to achieve "borderless" designs.

Cost: COF is significantly more expensive than COG due to the cost of the flexible substrate.Utility: For most industrial and medical applications, the cog lcd display offers the best balance of compactness and cost-efficiency. COF is usually overkill unless the device requires a foldable screen or zero bezel.

Why are engineers in the instrumentation and medical sectors migrating to this technology? The advantages go beyond just physical dimensions.

High-frequency noise is a common problem in industrial environments. Because the driver IC in a cog lcd display is mounted directly on the glass, the distance the signals must travel from the driver to the pixels is minimized. Shorter traces mean less susceptibility to electromagnetic interference (EMI) and crosstalk.

Since the IC is on the glass, the only connection leaving the display is a thin Flexible Printed Circuit (FPC). This FPC can be designed to bend, fold, or route through tight hinges.

Suppliers like Chuanhang Display frequently customize the FPC shape for clients. If your mainboard connector is located in an awkward spot, the FPC tail can be lengthened or angled to reach it, eliminating the need to redesign your main PCB.

In handheld meters or automotive applications, vibration is a killer. Traditional metal pins or zebra strips can shift over time, causing missing segments on the screen. The ACF bonding used in COG manufacturing is chemically stable and physically robust. Once cured, the bond is permanent and highly resistant to mechanical shock.

Understanding how these displays are made helps in vetting suppliers. The manufacturing process for a cog lcd display is precise and requires a clean-room environment.

The process begins with the "cleaning" stage, where the glass contact ledge is chemically scrubbed. If even a microscopic dust particle remains, it can cause an open circuit.

Next is the "ACF Lamination." A strip of conductive tape is applied to the glass. The driver IC is then picked and placed with micron-level accuracy.

The critical step is "Thermo-compression Bonding." A heated head presses the IC onto the glass. The heat melts the adhesive, and the pressure crushes the conductive gold balls inside the film to create the electrical connection.

Finally, the FPC is bonded to the glass using a similar process (FOG – Flex on Glass). A reputable manufacturer will perform a pull-force test on the FPC to ensure it won't detach during assembly at your factory.

When sourcing these components, pricing is structured differently than standard off-the-shelf parts.

Unlike standard modules, COG displays often require custom tooling. However, the cost is reasonable.

LCD Mask Charge: If you need a custom resolution or icon set.FPC Tooling: Usually low (often under $500).Backlight Tooling: Depends on the complexity of the plastic mold.

The unit price of a cog lcd display drops dramatically with volume. Because the assembly is highly automated, the labor cost is low. The main cost drivers are the driver IC and the glass itself.

Currently, in 2025, we are seeing stable prices for monochrome and simple TFT COG modules. However, shortages in specific high-voltage driver ICs can occur. Partnering with a supplier that holds strategic stock of wafers, such as Chuanhang Display, provides a buffer against market volatility.

The versatility of COG technology allows it to serve various sectors.

Blood glucose monitors, pulse oximeters, and handheld thermometers require screens that are lightweight and consume very little power. A reflective or transflective monochrome COG LCD is the standard choice here due to its low power draw, extending battery life.

E-bikes and electric scooters use COG displays for their speedometers and battery gauges. These displays must be sunlight-readable. By combining a high-transmissivity COG panel with a strong backlight, manufacturers can achieve excellent outdoor visibility.

In factory environments, Panel Light Controllers (PLCs) and server rack monitors use these displays to show status codes. The compact nature allows the screen to fit into 1U server racks where vertical space is extremely limited.

The market is flooded with traders, but finding a true manufacturer with engineering capability is key. When evaluating a potential partner for your cog lcd display needs, look for specific technical competencies.

Can the supplier modify the initialization code? If you change the main processor on your device, you may need to adjust the timing settings on the display driver. A "box mover" cannot help you here. Companies like Chuanhang Display employ engineers who can assist in debugging software drivers and optimizing contrast settings.

Industrial products often have a lifecycle of 5 to 10 years. You cannot use a consumer-grade display that will be discontinued in six months. Ask the manufacturer for a "Long-Term Supply Agreement." They should be able to guarantee that the specific glass and IC combination will remain in production for the foreseeable future.

You might find a standard screen that is almost perfect, but the backlight is too dim, or the FPC cable is too short. A flexible manufacturer will be willing to make these semi-custom modifications without demanding an exorbitant Minimum Order Quantity (MOQ).

Integrating a cog lcd display into your product requires care. Because the glass edge is exposed (where the IC sits), it is more fragile than a metal-framed module.

The housing of your device must protect the edges of the glass. The design should ensure that no physical stress is applied to the IC area. If the housing twists, the glass can crack near the bonding area. Using a foam gasket or a rubber bezel to "float" the display within the casing is standard practice.

The connection between the flexible cable and the glass is strong but not invincible. During assembly, workers should not pull the display by the tail. A strain relief design in the housing is recommended to prevent the FPC from tearing away from the glass ledge if the device is dropped.

The shift toward miniaturization in electronics is not slowing down. As devices become smarter and smaller, the cog lcd display remains the most logical solution for visualization. It strips away the unnecessary bulk of PCBs and bezels, leaving only what matters: the screen and the data.

For sourcing managers and engineers, the challenge is no longer just about finding the technology, but finding the right partner to implement it. It requires a supplier who understands the nuances of ACF bonding, FPC design, and long-term inventory management.

By prioritizing technical support and quality assurance, manufacturers like Chuanhang Display are helping industries transition away from legacy heavy displays to sleek, modern, and cost-effective COG solutions. Whether for a life-saving medical device or a rugged industrial meter, choosing the right display architecture is the first step toward a successful product launch.

Q1: What is the main advantage of a COG LCD display over a standard module?

A1: The primary advantage is size. By bonding the driver IC directly to the glass, the module becomes thinner and lighter, eliminating the need for a separate PCB and reducing the overall footprint on your device's motherboard.

Q2: Are COG displays more expensive than COB (Chip-on-Board) displays?

A2: In low volumes, COG might have higher initial tooling costs. However, for mass production, COG is often cheaper because it requires fewer components (no PCB, no bezel) and the manufacturing process is highly automated.

Q3: Can I repair a COG display if the driver IC fails?

A3: No, the bonding process using Anisotropic Conductive Film (ACF) is permanent. If the driver IC or the glass fails, the entire module must be replaced. Reworking a COG bond is not feasible in a standard repair shop environment.

Q4: What is the typical lead time for a custom COG LCD from Chuanhang Display?

A4: For a fully custom design, drawing approval takes about 3-5 days, tooling and sample production take 3-4 weeks, and mass production typically takes 4-6 weeks depending on the availability of the specific driver IC.

Q5: Can COG displays be used in outdoor environments?

A5: Yes, but the readability depends on the backlight and polarizer type. For outdoor use, you should request a "Transflective" polarizer and a high-brightness backlight customization to ensure the screen is readable in direct sunlight.