Looking for a reliable, readable, and cost-effective way to show numbers? You’ve probably landed on the seven segment display. These iconic components are more than just relics from old digital clocks. They are active, evolving solutions for modern electronics. Understanding their nuances can save you time, cost, and design headaches.

Let's break down the seven critical things you need to know before specifying a seven segment display for your next device.

It’s brilliantly simple. A standard seven segment display has eight elements: seven bars (segments) arranged in a figure '8', plus one decimal point. Each segment is a separate LED or liquid crystal cell.

By powering different combinations of these segments, you can form the numerals 0 through 9. This simplicity is its superpower. It requires minimal control logic compared to a full graphic display. For pure numeric output, nothing is more efficient.

The underlying technology, however, offers choices that define its application.

This is your first major decision. The performance gap is significant.

LED Seven Segment Displays are emissive. They generate their own bright, colorful light. Red is classic, but green, yellow, blue, and white are common. They offer wide viewing angles and excel in low-light or outdoor conditions. Their weakness is higher power consumption, especially for large, multi-digit units.

LCD Seven Segment Displays are transmissive or reflective. They don’t emit light; they block or allow the passage of a backlight or ambient light. This makes them incredibly power-efficient, perfect for battery-powered gadgets like calipers or thermometers. Readability depends entirely on the light source behind or around them.

For industrial panels needing visibility across a factory floor, choose LED. For a handheld medical device running on a coin cell, LCD is likely the answer.

Everyone knows clocks and calculators. But the seven segment display's robustness keeps it relevant in demanding fields.

Industrial Control Panels: PLC counters, timer displays, and calibration equipment. Their high brightness and simplicity resist failure in harsh environments.

Automotive Aftermarket: Boost gauges, voltage readouts, and gear indicators for enthusiast vehicles. They handle vibration and temperature swings well.

Retail & Hospitality: Digital price tags, queue management systems, and kitchen order timers. Their passive nature means they can be updated wirelessly and run for years.

Test & Measurement Equipment: Multimeters, power supplies, and signal generators. Engineers trust their clear, unambiguous readouts.

Home Appliances: Ovens, coffee makers, and smart thermostats. A custom seven segment display can be designed to match the appliance's aesthetic perfectly.

Sourcing isn't just about finding a catalog part. It's about finding a partner. A specialized manufacturer brings critical advantages.

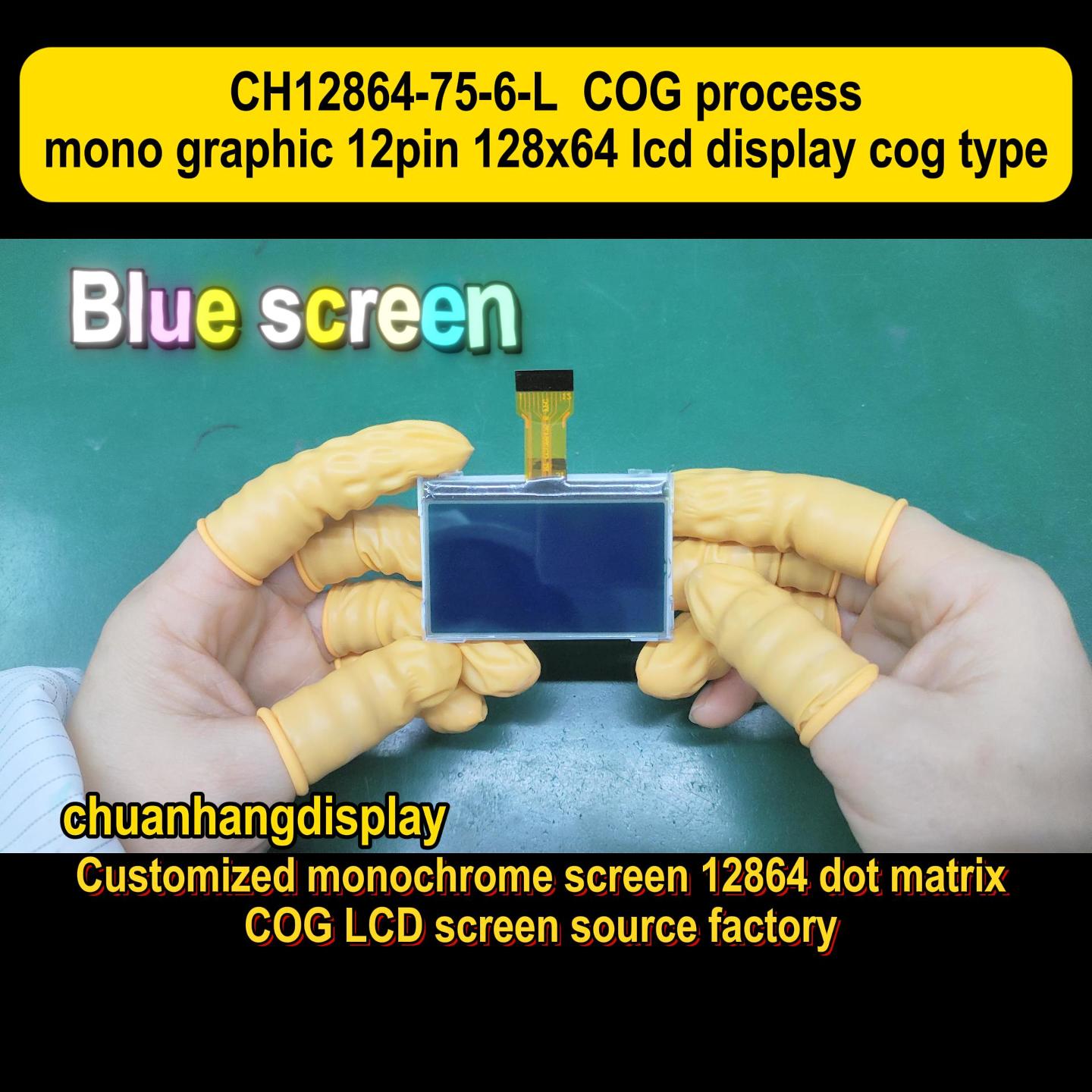

They understand the subtleties of die bonding for LED longevity or the fluid dynamics of LCD cell filling. They can advise on viewing angle specifications or optimal driving current. A company like Chuanhang Display, with deep roots in the international LCD and LED field, offers this engineering support.

More importantly, they enable customization. Need a specific shade of red? A non-standard digit height? A unique connector pinout? Off-the-shelf modules rarely fit perfectly. Working directly with a manufacturer turns your unique requirement into a standard process for them.

The sticker price per display is just the start. Consider the Total Cost of Integration.

Driving Electronics: A bare seven segment display needs driver ICs or transistors. LCDs may require a bias voltage generator. Some integrated modules include drivers, simplifying your PCB but at a higher unit cost.

Power Supply: A 4-digit LED display can draw 100mA or more. This impacts your power supply design and heat management. An LCD might add the cost of a backlight LED strip.

Assembly & Rework: Surface-mount (SMD) displays allow automated placement but may require reflow ovens. Through-hole types are easier to hand-solder but increase assembly time.

Sometimes, paying slightly more for a module with an integrated serial interface (like SPI or I2C) from a supplier like Chuanhang Display can slash overall development and production costs.

The manufacturing process ensures reliability. For an LCD seven segment display, it starts with patterning two glass substrates with transparent Indium Tin Oxide (ITO) electrodes in the segment pattern.

The glass is then coated with alignment layers, spaced with microscopic beads, and sealed with epoxy. The liquid crystal material is injected under vacuum into the tiny cell gap. This process, mastered by experienced manufacturers, defines clarity and prevents leaks.

For LED types, precision die attachment wire-bonds the tiny semiconductor chips for each segment onto a lead frame. The plastic lens cap is then molded for color and diffusion. Consistency here, batch after batch, is what separates a quality display from a problematic one.

The seven segment display isn't static. Trends are clear.

Integration is key. Displays now come with built-in controllers that communicate via simple digital protocols, reducing microcontroller pin count and software overhead.

Customization is expected. Brands want their user interface to be distinctive. This drives demand for custom seven segment display designs: unique fonts, integrated icons, special color filters, or curved glass faces. This is where a responsive manufacturer provides immense value.

Hybrid solutions are emerging. Think a standard seven-segment layout with an additional small graphic area for units (like °C or psi), all within one compact glass package.

Q1: What does "common anode" and "common cathode" mean for LED displays?

A1: This refers to how the LEDs inside are wired. In a common anode display, all the anodes (positive sides) of the segments are connected together. You ground the cathode of a segment to turn it on. In a common cathode display, the cathodes are shared. You apply voltage to the anode to light a segment. Your driver circuit must match the type.

Q2: Can I get a seven segment display in a color other than red or green?

A2: Absolutely. For LED types, blue, white, and true yellow are available. For LCDs, the color is determined by the backlight LED and the front polarizer filter. A supplier like Chuanhang Display can often provide a range of standard colors or develop a custom color match.

Q3: How do I control a multi-digit seven segment display without using too many microcontroller pins?

A3: The standard method is multiplexing. You rapidly cycle power (for LED) or signal (for LCD) between each digit, persisting the correct segment pattern for each. This lets you control, for example, an 8-digit display with only 8 segment pins + 8 digit select pins, instead of 64 individual pins.

Q4: What is the typical operating temperature range for these displays?

A4: It varies by technology. Standard commercial-grade LCDs range from about 0°C to +50°C. Industrial-grade LCDs can span -20°C to +70°C. LED displays typically handle -40°C to +85°C more easily, making them suitable for harsher environments. Always check the datasheet.

Q5: I need a very specific size and shape. Is that possible?

A5: Yes, this is a primary reason to engage with a manufacturer. Custom seven segment display designs are common. You can specify the exact digit height, overall footprint, glass shape, and segment layout. Companies like Chuanhang Display specialize in turning these specifications into production-ready designs, though tooling fees usually apply for fully custom parts.