In the world of electronic displays, choosing the right technology is critical for product performance and reliability. One technology that stands out for compact, high-quality designs is the COG LCD Screen. This article explains what COG LCDs are and why they are a preferred choice in many industries.

We will look at their technical structure, major advantages, and common uses. This information helps designers and procurement specialists make better decisions. Sourcing from a trusted manufacturer like Chuanhang Display ensures quality and consistency.

What is a COG LCD Screen?

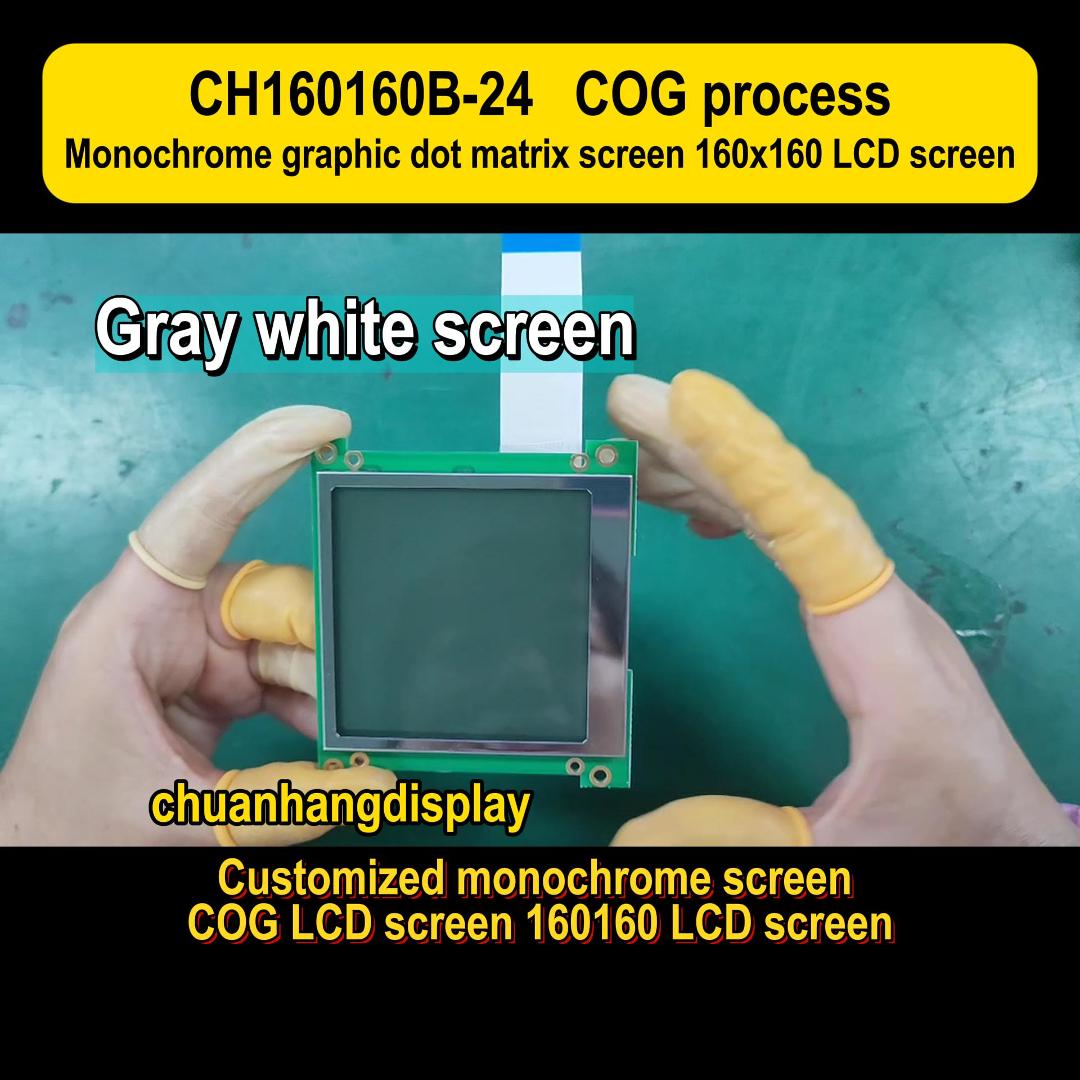

A COG LCD Screen is a type of liquid crystal display module. COG stands for "Chip-On-Glass." In this design, the driver Integrated Circuit (IC) is mounted directly onto the glass substrate of the LCD panel.

This method differs from older techniques like COB (Chip-On-Board). It creates a more integrated and compact unit. The result is a slimmer, more reliable display assembly.

Technical Structure of COG LCDs

The COG construction integrates several key components tightly. Understanding this helps see its benefits.

Glass Substrate: The base layer containing the liquid crystal matrix and transparent electrodes.

Driver IC: The silicon chip bonded directly onto the glass edges. It controls individual pixels.

Conductive Adhesive: A special material (like Anisotropic Conductive Film) that electrically connects the IC to the glass traces.

Backlight Unit: Provides illumination, typically using LEDs, placed behind the glass assembly.

This direct attachment removes the need for a separate PCB for the driver chip. It simplifies the overall module design significantly.

5 Major Advantages of COG LCD Technology

The COG LCD Screen offers distinct benefits over other packaging methods. These advantages solve common design challenges.

1. Compact Size and Slim Profile

Eliminating the external driver PCB greatly reduces the module's footprint and thickness. This is vital for modern portable devices.

Allows for ultra-thin product designs.

Saves valuable internal space for batteries or other components.

Enables smaller bezels around the display area.

For wearable tech and medical monitors, this space saving is often a decisive factor.

2. Enhanced Reliability and Durability

Fewer physical connections and components mean fewer points of potential failure. COG LCDs are known for robust performance.

Resistant to vibration and mechanical shock.

Less susceptible to connection corrosion or loose contacts.

Better performance in wide temperature ranges.

This makes them suitable for automotive dashboards and industrial equipment that face harsh conditions.

3. Improved Electrical Performance

The short connection paths between the driver IC and the display electrodes offer electrical benefits.

Lower electromagnetic interference (EMI).

Reduced signal delay and crosstalk.

Potential for lower power consumption.

These factors contribute to a stable, clear image and help devices meet strict electromagnetic compatibility standards.

4. High-Resolution Potential

The COG method supports a high number of connections from the IC to the glass. This enables control over more pixels in a small area.

It is an excellent choice for displays that need fine detail. Examples include advanced handheld instruments or high-density character displays.

5. Cost-Effectiveness in Volume Production

While the initial setup and glass design have costs, COG becomes very economical for large-scale manufacturing.

Simpler final assembly process.

Reduced material count (no separate PCB, connectors, or bonding wires).

Lower overall module cost at high volumes.

Brands like Chuanhang Display leverage efficient production to offer competitive pricing for bulk orders.

Common Applications of COG LCD Screens

The unique strengths of the COG LCD Screen make it ideal for specific market segments. Here are its primary uses.

Consumer Electronics

This is a major application area where thinness and reliability are demanded.

Smartwatches & Wearables: Minimal space and light weight are critical.

Portable Gaming Devices: Requires durable screens that can handle movement.

Home Appliances: Used in advanced control panels for ovens, coffee makers, etc.

Industrial and Automotive Systems

Environments that are challenging for electronics benefit from COG's durability.

Industrial Control Panels: For factory machines and measurement tools.

Automotive Displays: In dashboard instrument clusters, radio units, or rear-seat entertainment.

Handheld Terminals: Used in logistics, retail, and field service.

Medical and Healthcare Devices

Medical equipment requires dependable, clear displays often in compact form factors.

Portable Monitors: For vital sign tracking.

Diagnostic Equipment: Displays readings in infusion pumps, glucose meters, etc.

Home Care Devices: Integrated into personal health gadgets.

Choosing a Reliable COG LCD Screen Supplier

Selecting the right manufacturer is as important as understanding the technology. A good partner ensures product success.

Key Supplier Evaluation Criteria

Consider these points when sourcing COG LCD Screen modules.

Engineering Support: Can they help with custom specifications and interface integration?

Quality Control: Do they have certifications (ISO, RoHS) and rigorous testing processes?

Production Capacity: Can they handle your required volume and deliver on time?

Prototyping Services: Do they offer fast samples for design validation?

Long-term Stability: Will they be a reliable partner for future product cycles?

Why Consider Chuanhang Display

Chuanhang Display has extensive experience in manufacturing COG LCD screens. They provide solutions that balance performance with cost.

Their services often include custom design adjustments, comprehensive testing, and global logistics support. This makes them a strong option for businesses looking for a dependable supply chain partner in the display industry.

The COG LCD Screen is a sophisticated display solution that addresses key needs for compactness, reliability, and performance. Its chip-on-glass design offers clear advantages for a wide range of modern electronic products.

For engineers and buyers, understanding these benefits helps in selecting the right display technology. Working with established manufacturers like Chuanhang Display ensures access to high-quality COG LCD modules and the technical expertise needed for successful implementation.

Frequently Asked Questions about COG LCD Screens

Q1: What is the main difference between COG and COB LCD screens?

A1: In COG (Chip-On-Glass), the driver IC is bonded directly onto the glass substrate. In COB (Chip-On-Board), the IC is mounted on a separate printed circuit board (PCB) which is then connected to the glass. COG is generally thinner and more integrated.

Q2: Are COG LCD screens more expensive than other types?

A2: The initial cost for tooling and glass design can be higher. However, for medium to high volume production, the total cost per unit is often lower due to simpler assembly and fewer materials, making them cost-effective.

Q3: Can COG LCD screens support touch functionality?

A3: Yes. Touch panels (resistive or capacitive) can be laminated onto a COG LCD module to create a complete touch screen unit. This is a common configuration for interactive devices.

Q4: What are the typical size and resolution limits for COG technology?

A4: COG is excellent for small to medium-sized screens, typically from 1 inch to 10 inches diagonally. It supports a wide range of resolutions, from simple character displays to high-density graphics, limited mainly by the driver IC capability and glass manufacturing process.

Q5: How do I interface with a COG LCD screen from my microcontroller?

A5: COG LCDs usually provide standard digital interfaces such as SPI, I2C, or parallel (8080/6800 series). You need to connect the screen's pins to your microcontroller and use the appropriate driver software or library, often provided by the supplier like Chuanhang Display.