If you’ve ever taken apart a digital calculator, a smart thermostat, or a handheld medical device, you’ve likely seen one. It’s a flat, clean glass panel with no visible connecting cables—just a dark stripe along one edge with subtle metallic traces. This is a COG LCD screen.

COG stands for Chip-On-Glass. It represents a fundamental LCD assembly technology that prioritizes miniaturization, reliability, and cost-effectiveness for high-volume production. Unlike standard modules with a separate driver circuit board, the brains of the display are bonded directly onto the glass itself.

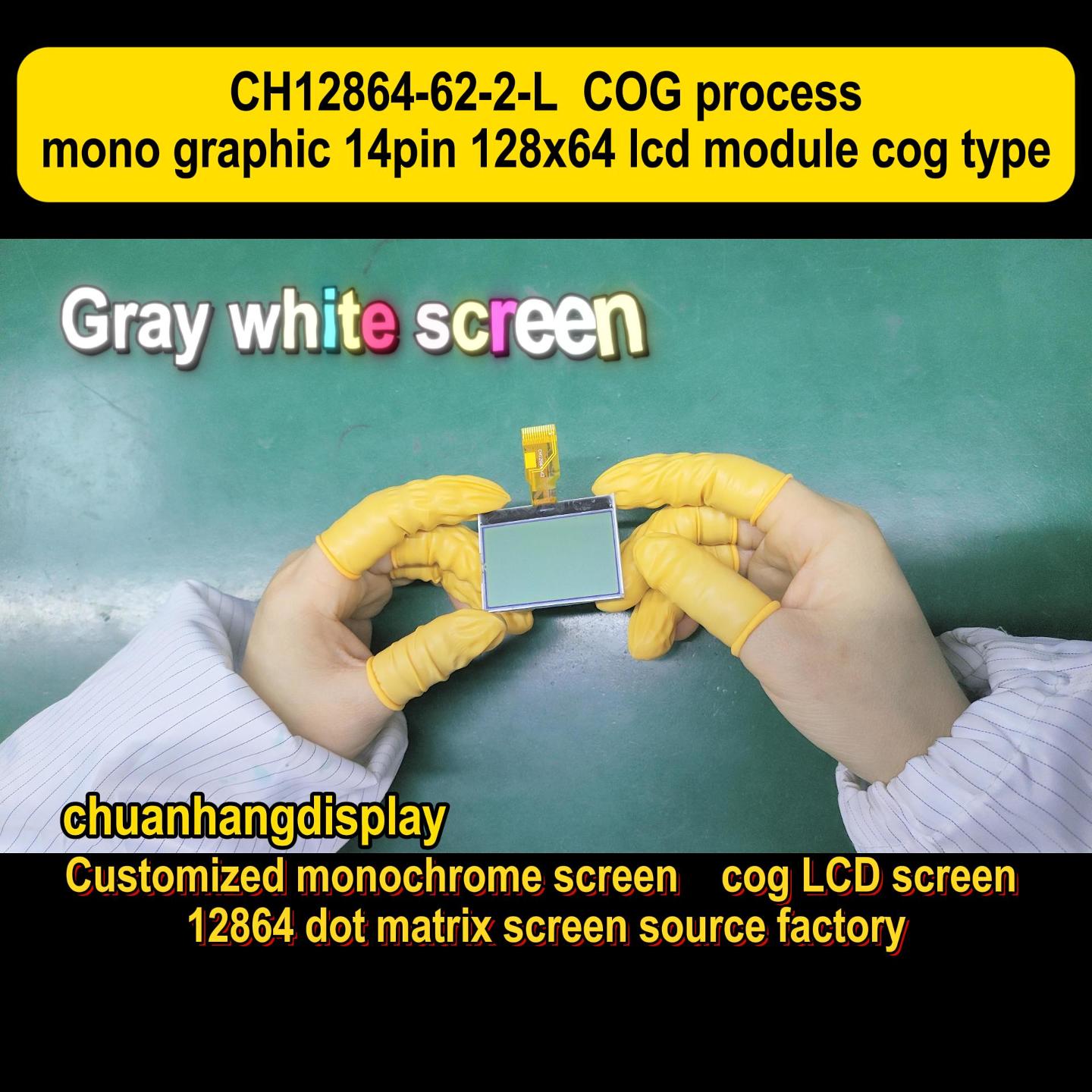

For engineers designing space-constrained or battery-powered devices, understanding this technology is crucial. It’s a staple in the product lines of specialized manufacturers like Chuanhang Display, who supply these screens to industries worldwide.

The core idea of the COG process is integration. Tiny silicon driver chips are mounted directly onto the conductive ITO (Indium Tin Oxide) pads of the LCD glass substrate.

This is done using a precise anisotropic conductive film (ACF) bonding process. The ACF contains microscopic conductive particles that, under heat and pressure, create electrical connections between the chip’s bumps and the glass pads.

The result is a single, unified component. The integrated circuit drivers control the pixels, eliminating the need for a traditional printed circuit board (PCB) bonded to the glass via fragile zebra strips or elastomeric connectors.

This direct attachment is what defines a true COG LCD screen.

The benefits of this integrated approach solve several common design challenges.

First is size and form factor. Removing the separate connector and driver PCB significantly reduces the overall thickness and footprint of the display assembly. This is invaluable for ultra-thin or miniature products.

Second is enhanced reliability. With fewer physical connection points (no solder joints on a separate PCB, no connector interface), the assembly is more resistant to shock, vibration, and corrosion. This leads to a longer operational lifespan.

Third is cost-effectiveness at scale. While the initial setup and tooling (like the bonding mask) require investment, the per-unit cost for high-volume orders becomes very competitive. The assembly process is also highly automatable.

It’s helpful to contrast COG with other common methods to see its niche.

COB (Chip-On-Board): Here, the driver chip is mounted on a separate PCB, which is then connected to the glass. COB offers more flexibility for additional circuitry but results in a thicker module.

TAB (Tape-Automated Bonding): The chip is mounted on a flexible plastic tape, which is then bonded to the glass. TAB can accommodate finer pitch chips but often involves more process steps.

Standard LCD Modules: These have a visible PCB attached, often with a pin header or FPC connector. They are easier to prototype with but are bulkier and have more potential points of failure than a COG LCD screen.

COG sits at the sweet spot for applications needing the thinnest, most reliable, and streamlined integrated display.

You interact with COG-based displays more often than you think.

Consumer Electronics: Digital kitchen scales, universal remote controls, and basic smart home interfaces rely on their slim profile and durability.

Medical Devices: Blood glucose meters, portable thermometers, and infusion pump displays use COG for its reliability in critical, often handheld, applications.

Industrial Controls: Durable control panels for machinery, HVAC systems, and measurement tools benefit from the technology’s resistance to harsh environments.

Automotive Clusters: Simple secondary displays for trip computers or climate control in vehicles often use COG for its robust construction.

Retail & Handheld Terminals: Inventory scanners and point-of-sale devices use them for their resistance to daily physical wear and tear.

Specifying a COG display requires careful planning.

The tooling cost for the bonding mask is a primary factor. This makes the technology less economical for very low-volume prototypes. Many designers start with a standard module and switch to COG for mass production.

Customization is a strength. Companies like Chuanhang Display work with clients to tailor the glass size, the viewing mode (positive, negative, transmissive, transflective), and the integrated driver’s capabilities to the exact need.

Testing is critical. Once the chip is bonded, repairs are nearly impossible. Ensuring rigorous electrical testing after bonding is a standard part of a quality manufacturer’s process.

A reliable manufacturer does more than just bond chips to glass. They provide essential front-end support.

This includes design consultation to optimize the glass layout for bonding and ensure the driver IC matches the application’s requirements.

Prototyping support, perhaps using a temporary adhesive or providing a near-equivalent module, helps clients validate their design before committing to production tooling.

Finally, consistent quality control throughout the cleaning, bonding, and testing processes ensures every COG LCD screen that leaves the factory meets strict performance and reliability standards.

For product designers navigating the trade-offs between size, cost, and durability, the COG LCD screen remains an indispensable solution. Its elegant integration of silicon and glass continues to enable sleek, reliable, and efficient devices across countless market segments.

When considering this technology, partnering with an experienced manufacturer such as Chuanhang Display can streamline the journey from concept to high-volume manufacturing.

Q1: Is a COG LCD screen more expensive than a standard LCD module?

A1: For low volumes, yes, due to tooling costs. For high-volume production (typically thousands of units), the per-unit cost of a COG assembly often becomes lower and more economical than modules with separate PCBs and connectors.

Q2: Can a COG display be repaired if it fails?

A2: Practically, no. The driver chip is permanently bonded to the glass. If the chip or the glass fails, the entire display unit must be replaced. This underscores the importance of quality in the initial manufacturing.

Q3: Are COG displays suitable for use in extreme temperatures?

A3: They can be, depending on specifications. The bonding materials and liquid crystal fluid must be selected for the target temperature range. It’s essential to discuss your environmental requirements with your supplier, like Chuanhang Display, who can specify appropriate materials.

Q4: How do I connect to a COG LCD screen in my product?

A4: Connection is made via the exposed ITO traces on the glass, which are typically routed to a flat flex cable (FFC) connector or bonded directly to your main PCB using the same ACF process. Your product’s PCB will interface with these traces.

Q5: Can I get a custom-shaped COG display?

A5: Yes. One of the advantages of COG technology is the flexibility in glass shaping. The glass substrate can be cut into various shapes (round, oval, with notches) before the chip is bonded, enabling unique and space-efficient designs.