In the world of compact, power-efficient electronics, the term cog module is fundamental. If you've ever used a smartwatch, a portable medical device, or a handheld scanner, you've likely interacted with one. But what exactly is this component, and why is its design so critical for modern devices? This article delves into the specifics of COG LCD Module technology, the role of a reliable COG LCD module Manufacturer, the intricacies of the COG module Assembly process, and the advantages of opting for a custom cog module. We will also explore common challenges and solutions, highlighting the expertise of Chuanhang Display in this specialized field.

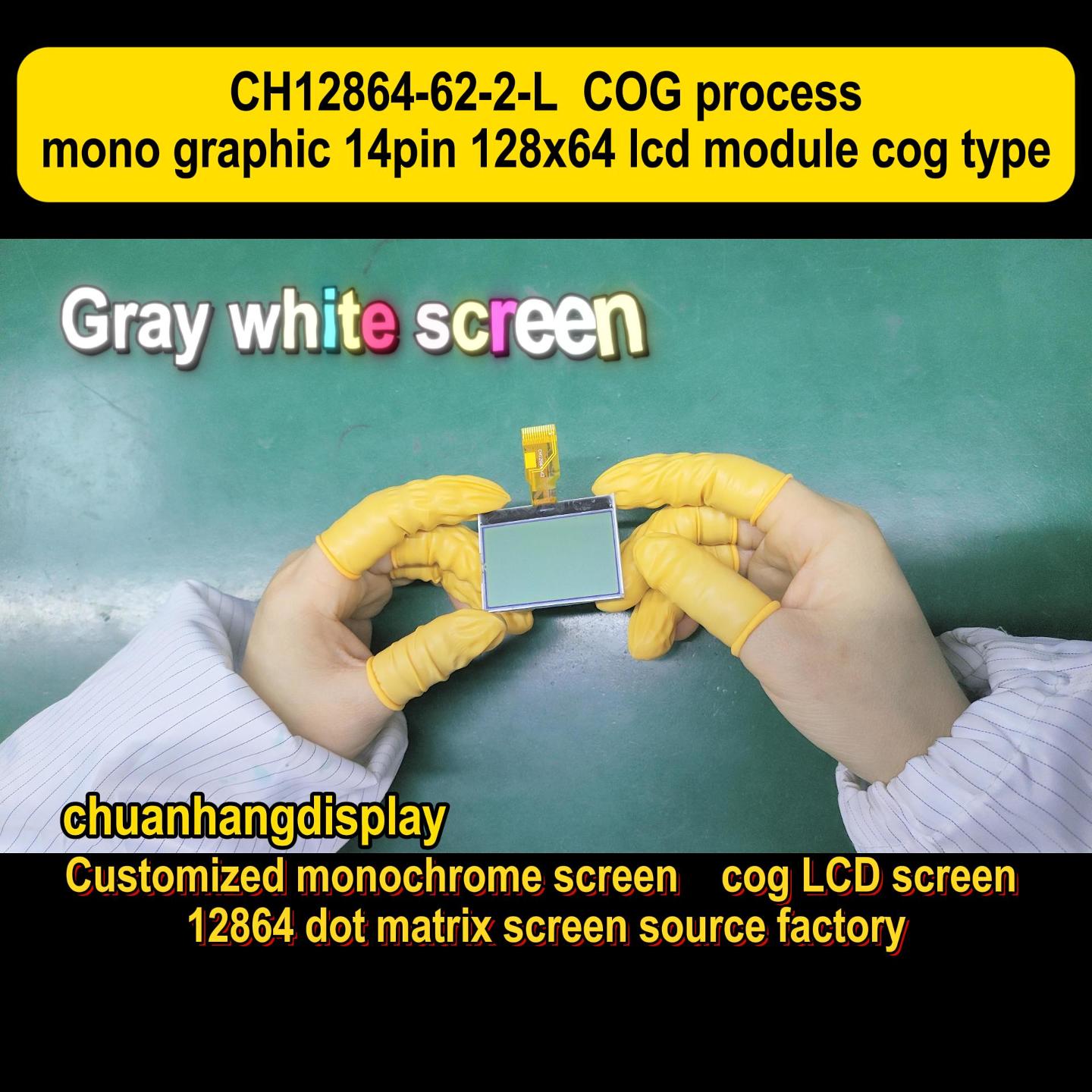

A COG LCD Module (Chip-On-Glass Liquid Crystal Display Module) represents a significant advancement in display technology. Unlike traditional displays where the driver IC is mounted on a separate printed circuit board (PCB) connected via flex cables, the cog module integrates the driver chip directly onto the glass substrate of the LCD itself.

This direct attachment eliminates the need for a Tape Carrier Package (TCP) or a separate connector, leading to a more compact, lightweight, and robust design. The result is a display assembly with a smaller footprint, reduced electromagnetic interference, and often, lower power consumption. The cog module is the go-to solution for applications where space, weight, and reliability are paramount. From consumer electronics like fitness trackers to critical industrial and medical equipment, the COG LCD Module provides a clear, reliable interface in a minimalistic form factor.

Partnering with an experienced COG LCD module Manufacturer is crucial for bringing a high-quality product to market. A manufacturer like Chuanhang Display does not merely assemble components; they provide end-to-end solutions encompassing design support, material sourcing, precision manufacturing, and rigorous testing.

A proficient COG LCD module Manufacturer brings several key strengths to the table:

Engineering Expertise: They understand the nuances of bonding ICs to glass, ensuring strong electrical connections and long-term durability.

Quality Control: They implement stringent quality checks throughout production, from glass cutting and cleaning to the final COG module Assembly, to prevent defects like dead pixels or connection failures.

Supply Chain Stability: They have established relationships with suppliers of high-quality glass, driver ICs, and polarizers, ensuring consistent material availability and performance.

Chuanhang Display, as a leading COG LCD module Manufacturer, exemplifies this by offering technical consultation to help clients select the optimal display parameters—such as resolution, viewing angle, and temperature range—for their specific application.

The COG module Assembly process is a delicate and precise operation that demands a cleanroom environment and sophisticated equipment. Understanding this process highlights why manufacturing expertise is so vital.

The key steps in a typical COG module Assembly line include:

Substrate Preparation: The ITO (Indium Tin Oxide) coated glass panels are meticulously cleaned to remove any contaminants that could impair adhesion.

Anisotropic Conductive Film (ACF) Lamination: ACF, a key bonding material, is pre-laminated onto the contact pads of the glass substrate. This film contains microscopic conductive particles suspended in an adhesive resin.

Chip Placement and Bonding: This is the core of the cog module process. The driver IC is precisely aligned onto the ACF-coated contact pads. Using a thermode (a heated tool), heat and pressure are applied. This process cures the adhesive in the ACF, creating a permanent mechanical bond, while the conductive particles are crushed to form electrical connections between the IC bumps and the glass pads.

Testing and Integration: After bonding, the assembly undergoes electrical testing. If it passes, the cog module is then integrated with the backlight unit, touch panel (if applicable), and bezel to form a complete display module.

Any misstep in the COG module Assembly, such as incorrect alignment, uneven pressure, or contamination, can lead to immediate failure or latent defects.

While standard COG LCD Module products suit many applications, off-the-shelf solutions often fall short for projects with unique requirements. This is where a custom cog module becomes essential.

You might need a custom cog module for:

Unique Form Factors: Your product may require a non-standard shape, size, or aspect ratio that isn't available in catalog offerings.

Specific Performance Needs: Applications may demand an extended operating temperature range (e.g., for automotive or outdoor use), ultra-low power consumption, or a specialized viewing mode like transflective for sunlight readability.

Integrated Features: You might need to integrate a capacitive touch panel, a specific connector type, or an anti-glare/anti-smudge coating directly into the module.

Developing a custom cog module requires close collaboration with a manufacturer. Chuanhang Display specializes in such collaborations, working with clients from the conceptual stage to develop a tailored COG LCD Module that meets exact mechanical, electrical, and optical specifications, ultimately accelerating time-to-market and ensuring a perfect fit for the end product.

Despite their robustness, cog modules can encounter issues. Being aware of these common problems can aid in both design and troubleshooting.

Display Failure or No Image:

Cause: This is often due to a break in the electrical connection. It could be a failure in the ACF bonding during COG module Assembly, a cracked driver IC, or physical damage to the glass traces.

Solution: Verify the power supply and input signals first. If those are correct, the issue likely lies within the module itself and requires replacement. Working with a reputable COG LCD module Manufacturer minimizes the risk of such assembly-related defects.

Partial Display or Missing Segments:

Cause: This typically points to a faulty connection on specific lines from the driver IC to the LCD. This can be caused by contamination during bonding, uneven pressure from the thermode, or electrostatic discharge (ESD) damage.

Solution: This is usually a non-repairable module-level fault. Prevention through a controlled COG module Assembly process and proper ESD protection is key.

"Ghosting" or Image Persistence:

Cause: This can be caused by DC voltage imbalance across the LCD pixels, often related to the driving scheme or a slight mismatch in the electrical characteristics of the cog module.

Solution: Ensure the controller's driving waveform matches the module's specifications. A high-quality COG LCD Module from a supplier like Chuanhang Display will have consistent electrical characteristics, reducing the likelihood of such issues.

Short Lifespan in Harsh Environments:

Cause: Exposure to extreme temperatures, humidity, or mechanical vibration can degrade the ACF bond or damage the fragile glass.

Solution: For demanding applications, specify a custom cog module built with enhanced materials, such as wide-temperature liquid crystals and strengthened glass, and ensure it is properly potted or sealed within the end device.

The cog module is more than just a component; it is an enabling technology for the sleek, powerful, and portable devices that define our era. From the standard COG LCD Module to a fully tailored custom cog module, this technology offers unparalleled advantages in miniaturization and reliability. However, reaping these benefits depends heavily on the expertise of your COG LCD module Manufacturer and the precision of the COG module Assembly process.

By understanding the technology, its potential pitfalls, and the value of a collaborative manufacturing partnership with experts like Chuanhang Display, designers and engineers can confidently leverage cog modules to create the next generation of innovative electronic products.