In the electronics industry, visual feedback is essential for user interaction. Engineers often prioritize reliability and low power consumption when selecting a display interface. The 7 Segment LCD remains one of the most efficient solutions for displaying numerical data.

These displays consist of liquid crystals arranged in a pattern to form numbers and basic characters. Unlike modern high-resolution screens, they do not require complex processors to operate. This simplicity makes them ideal for battery-powered devices.

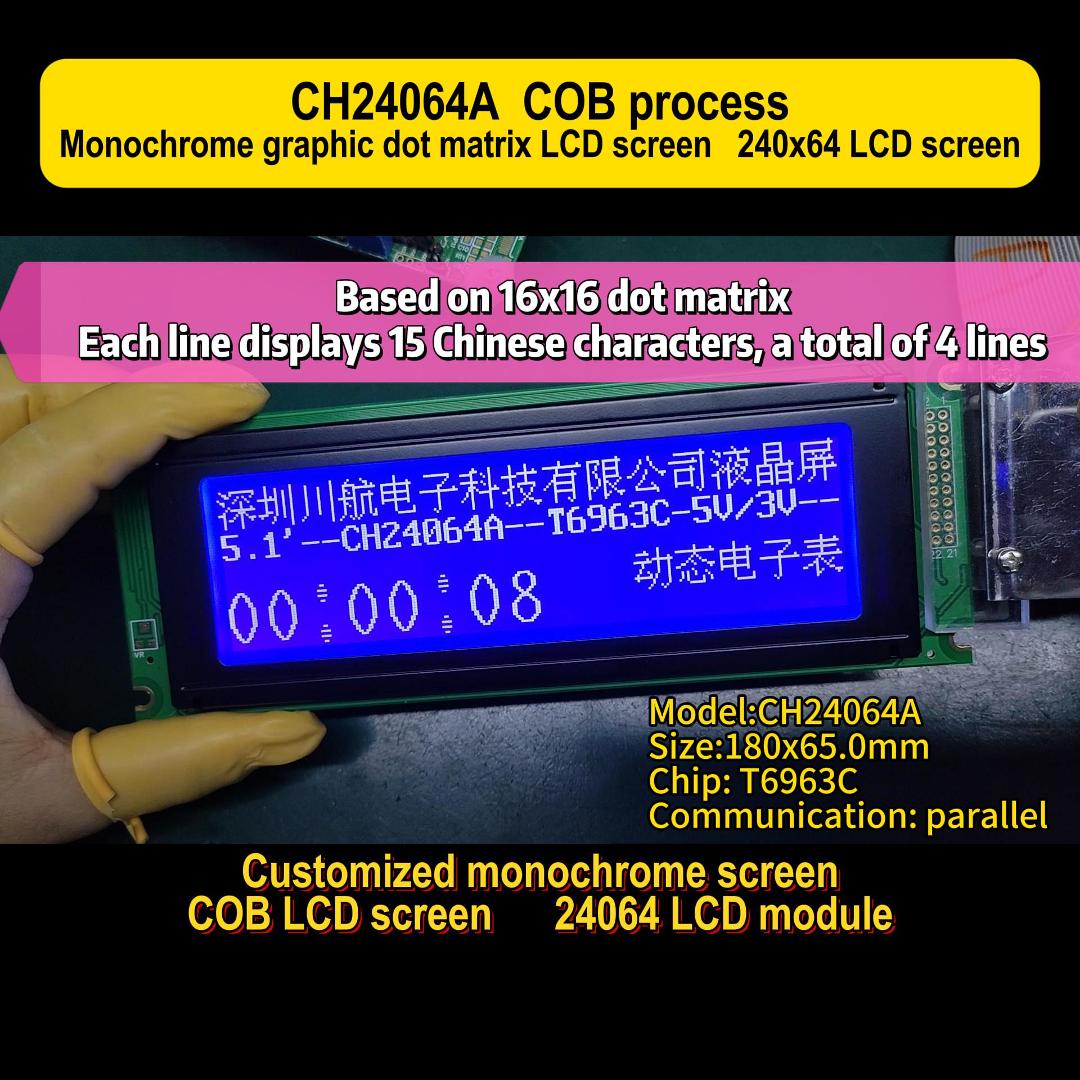

Companies like Chuanhang Display specialize in manufacturing these components for various sectors. Whether for medical devices or industrial meters, understanding the technical specifications of these screens is vital for project success.

The core concept behind this technology is straightforward yet effective. Each digit on the screen is composed of seven separate segments labeled A through G. By activating specific segments, the display creates numbers from 0 to 9.

Liquid Crystal Display (LCD) technology relies on light modulation. The segments themselves do not emit light; instead, they block or pass light based on the electrical current applied. This passive nature is the primary reason for their energy efficiency.

A standard digit layout includes a decimal point, often referred to as the "DP" or eighth segment. The arrangement is standardized to ensure compatibility across different driver ICs.

Top Segment (A): Forms the upper horizontal line.

Middle Segment (G): The central horizontal bar.

Bottom Segment (D): The lower horizontal base.

Side Segments (B, C, E, F): The vertical bars completing the figure 8 shape.

Engineers must map these segments correctly to the microcontroller (MCU). Incorrect mapping results in garbled characters, which is a common issue during the prototyping phase.

Not all numeric displays look the same. The visual performance depends heavily on the fluid type used inside the glass layers. Twisted Nematic (TN) is the most common and cost-effective option for a 7 Segment LCD.

TN displays offer a viewing angle of roughly 90 degrees. This is sufficient for handheld instruments like multimeters or calculators. However, some applications require wider visibility.

High Twisted Nematic (HTN) and Super Twisted Nematic (STN) fluids improve contrast and widen the viewing angle. STN is often preferred when the device will be viewed from multiple positions, though it comes at a slightly higher production cost.

Despite the rise of TFT and OLED screens, segment displays maintain a strong market share. Their longevity in the market proves their utility in specific engineering scenarios.

The primary benefit is power consumption. A static or low-duty segment display draws microamps of current. This is critical for devices that must run on coin-cell batteries for years.

Sunlight readability is a major challenge for light-emitting displays like LEDs. In direct sunlight, LEDs can wash out and become invisible.

A reflective 7 Segment LCD uses ambient light to function. The brighter the sun, the higher the contrast. This makes them the standard choice for outdoor equipment, such as gas pump meters and agricultural tools.

Budget constraints often drive component selection. Manufacturing a segment glass panel involves fewer layers and simpler driver electronics compared to dot-matrix graphic modules.

Chuanhang Display helps clients optimize tooling costs. By customizing the pinout and glass size efficiently, the unit price remains low, which is essential for high-volume consumer electronics.

Off-the-shelf components do not always fit unique housing designs. Customization allows engineers to tailor the display dimensions and functionality to the product.

Designers can specify the overall glass size, the viewing area, and the connector type. Common connector options include metal pins, heat seal connectors (HSC), or conductive rubber strips (Zebra).

The bottom polarizer determines how the display handles light. Selecting the right polarizer is crucial based on the operating environment of the device.

Reflective: Has a mirror-like backing. No backlight is needed. Best for well-lit environments.

Transmissive: Requires a backlight to be visible. Used in dark environments.

Transflective: A hybrid solution. It reflects ambient light but allows a backlight to shine through, working well in both day and night conditions.

Standard LCD fluids function between 0°C and 50°C. However, industrial and automotive applications often require wider tolerances.

Wide-temperature fluids allow a 7 Segment LCD to operate from -20°C to +70°C or even -30°C to +80°C. This prevents the liquid crystal from freezing in cold climates or turning black in extreme heat.

The versatility of segment technology allows it to penetrate numerous market verticals. Simplicity is often synonymous with reliability in critical systems.

Blood pressure monitors, glucose meters, and digital thermometers rely on segment screens. These devices display critical numbers that must be read without ambiguity.

The high contrast of a black-on-white or black-on-yellow/green display ensures that patients and doctors do not misread vital statistics.

Utility meters for water, gas, and electricity typically use this technology. These meters are often installed outdoors and must endure years of operation without battery replacement.

The static drive method used in many of these meters ensures the display remains on continuously with negligible power drain.

Microwave ovens, coffee makers, and washing machines utilize custom segment displays. They provide timers and status indicators effectively.

Brands work with manufacturers like Chuanhang Display to add custom icons (like a spinning drum or coffee cup) alongside the standard 7-segment numbers.

Designing a custom LCD requires attention to electrical parameters. Ignoring these details can lead to "ghosting" or poor contrast ratios.

Direct drive (Static) is the simplest method, where each segment has a dedicated pin. However, for displays with many digits, this requires too many pins on the microcontroller.

Multiplexing reduces pin count. A display might operate at 1/4 Duty, meaning it is powered on for only 25% of the time, but flashes fast enough that the human eye sees a solid image.

Bias voltage defines the steps of voltage used to drive the LCD. Correct bias settings are essential to prevent inactive segments from becoming visible (ghosting).

Engineers must match the bias setting of the LCD glass (e.g., 1/3 Bias) with the capabilities of the driver IC being used in the main circuit board.

Selecting a vendor is as important as selecting the technology. Chuanhang Display has established itself as a reliable partner in the display industry.

They offer comprehensive engineering support, helping clients move from a hand-drawn sketch to a fully functional prototype. Their quality control processes ensure that every batch meets strict industrial standards.

Furthermore, they provide flexible Minimum Order Quantities (MOQs). This support is valuable for startups and established enterprises launching niche products.

Even with a robust design, issues can arise during integration. Understanding common failure modes helps in rapid debugging.

If the display looks washed out, the driving voltage (VLCD) might be too low. LCDs require a specific voltage to twist the crystals fully.

Adjusting the contrast circuit or checking the battery level usually resolves this. Cold temperatures can also cause temporary fading if the fluid is not rated for the environment.

Ghosting occurs when segments that should be off appear faintly visible. This is often a result of incorrect bias settings or driving voltage that is too high.

Ensuring the refresh rate and voltage levels match the specification sheet of the 7 Segment LCD is the standard fix for this phenomenon.

LCDs have a preferred viewing direction, usually defined like a clock face (e.g., 6:00 or 12:00).

If a display looks inverted or unreadable from the front, it may have been manufactured with the wrong viewing direction for the device's mounting angle.

While the technology is mature, innovation continues. Vertical Alignment (VA) displays represent the premium end of the segment market.

VA technology provides a pitch-black background with ultra-high contrast segments. This mimics the look of LED or OLED but retains the simplicity of LCD driving.

Manufacturers are also developing thinner glass substrates. This allows for lighter end-products, contributing to the trend of sleek, wearable technology.

The 7 Segment LCD remains a cornerstone of industrial and consumer electronics design. Its unmatched power efficiency, sunlight readability, and low cost make it irreplaceable for many applications.

From simple thermometers to complex industrial controllers, these displays deliver data clearly and reliably. Understanding the nuances of TN vs. STN, reflective vs. transflective, and drive modes ensures optimal product performance.

For companies seeking high-quality display solutions, partnering with experts like Chuanhang Display guarantees access to top-tier manufacturing and technical support. A well-designed display serves as the reliable face of your technology.