From the digital clock on your bedside table to the weighing scale in your kitchen, a specific type of component is quietly presenting numbers. This component is the seven segment display. It's a foundational piece of electronic technology that converts electrical signals into easily readable numeric digits.

Despite the proliferation of full dot-matrix screens, this display method remains irreplaceable in countless applications. Its strength lies in perfect clarity for its intended purpose. This article breaks down how it functions, explores its various forms like LED and LCD, and provides concrete advice for selecting the right unit. We'll also touch on practical aspects like cost drivers and what to expect from a specialist supplier such as Chuanhang Display.

The name describes it perfectly. It is a device for presenting decimal digits using seven individual segments. These segments are arranged in a rectangular figure-eight pattern.

Each segment is an independent light-emitting or light-modulating element. They are labeled 'a' through 'g'. By powering different combinations, all numbers from 0 to 9 can be formed. An eighth segment, a decimal point, is often included.

Control is handled by an integrated circuit called a decoder-driver or directly by a microcontroller. This circuit maps a binary-coded decimal (BCD) input to the correct output pins to light the required segments.

The user experience of a seven segment display is defined by its underlying technology. The two most prevalent types today are LED and LCD.

LED-Based Displays

Light Emitting Diode (LED) versions are the most common. Each segment contains one or more LED chips. They are known for high brightness, vivid colors, and wide viewing angles. They work well in low-light conditions.

Their drawbacks include higher power consumption compared to LCDs. In very dark environments, they can be too bright without proper dimming control. They are also generally limited to a single, uniform color per digit.

LCD-Based Displays

Liquid Crystal Display (LCD) units operate on a different principle. They do not produce light. Instead, they use the modulating properties of liquid crystals to block or transmit reflected light.

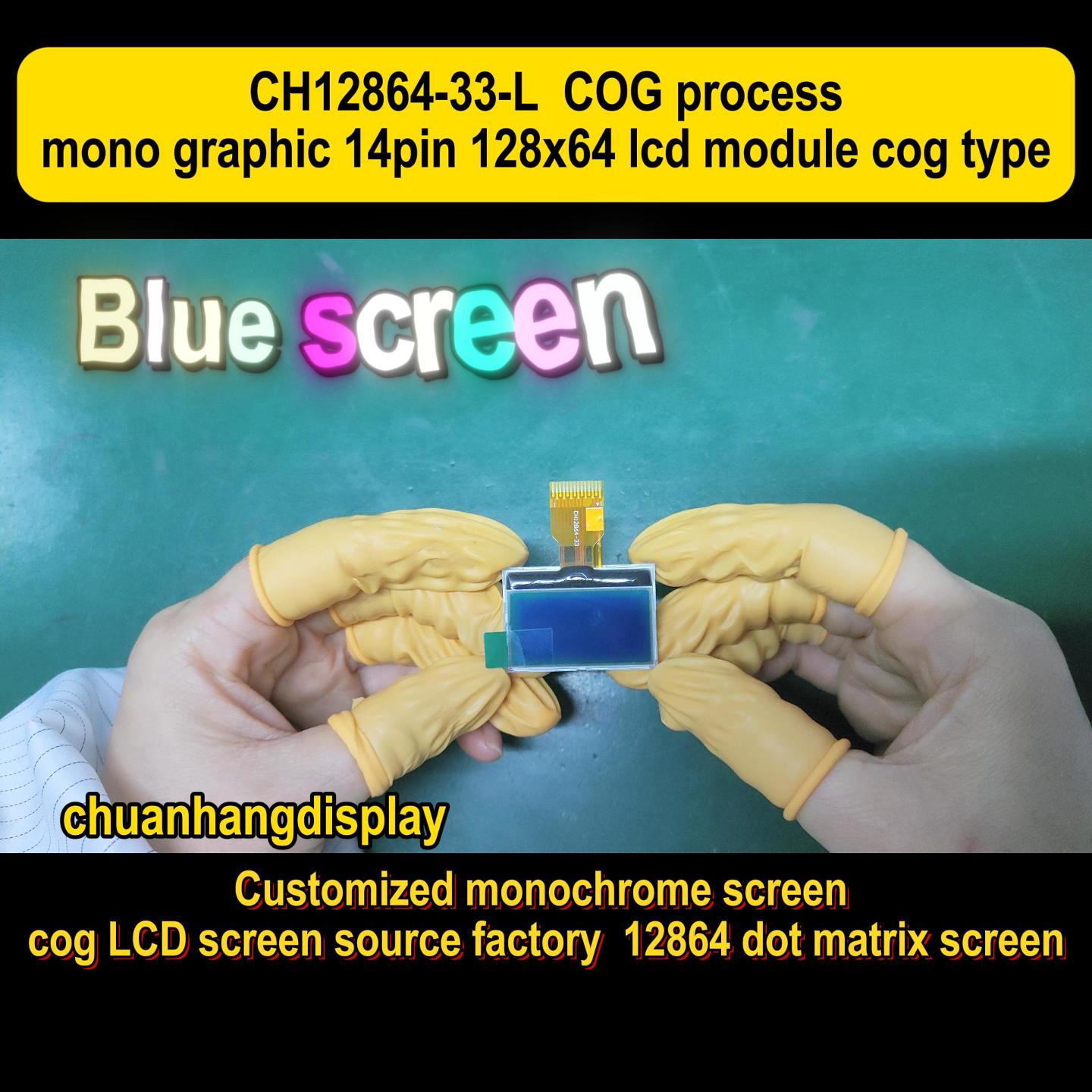

This makes them exceptionally readable in bright, ambient light, like direct sunlight. Their power consumption is extremely low, making them ideal for battery-powered devices. They require a frontlight or backlight for use in darkness. Chuanhang Display produces highly reliable LCD variants for instrumentation.

Other Variants

While less common today, Vacuum Fluorescent Displays (VFD) offer a distinctive bright blue-green glow and wide temperature tolerance. Electroluminescent (EL) and incandescent versions are now niche products.

The application list is vast due to the display's simplicity and effectiveness. Anywhere a clear, unambiguous number is needed, this technology is a candidate.

Consumer electronics form the largest market. Microwave ovens, washing machines, thermostats, and calculators all use them. The automotive industry integrates them into dashboard clusters for odometers and gear indicators.

In industrial settings, they are the standard for process control readouts, digital panel meters, and test equipment like multimeters. Their high reliability and failure resistance are key advantages here.

Choosing the right component involves answering a few practical questions. The environment comes first. For outdoor or brightly lit indoor use, an LCD or a high-brightness LED is necessary. For indoor control panels, a standard LED is often perfect.

Power budget is critical. Portable, battery-driven devices almost always use LCDs for their microamp-level current draw. Mains-powered equipment can freely use LEDs.

Consider the required size and color. Digit heights range from a few millimeters to over 200mm for large signage. LEDs offer red, green, yellow, and blue. LCDs typically present a black/gray image on a silver or transmissive background.

Finally, understand the interface. You must know if you need a common-anode or common-cathode configuration to design your driving circuit correctly.

For product developers, finding a capable manufacturer is as important as the technical specifications. A good supplier provides consistency, support, and customization options.

Look for a partner with a strong engineering background. They should help with footprint compatibility, optical filter selection for LCDs, and driver recommendations. Reliable sample programs and clear documentation are signs of a professional operation.

A company like Chuanhang Display operates with these principles. They support clients from prototype stages through mass production, ensuring component longevity and supply chain stability. This reduces risk for long-term product lines.

Unit pricing is influenced by several clear factors. The core technology sets a baseline; standard LED packages are very cost-effective, while custom or high-brightness LEDs cost more.

Customization always adds expense. This includes non-standard digit heights, special colors, integrated connectors, or on-board driver chips. Order volume has the most dramatic impact. Unit price for a large production run is a fraction of a small prototype batch.

Additional features like extended temperature ranges, higher ingress protection (IP) ratings, or conformal coatings also increase cost. A transparent discussion with your supplier about requirements and volumes is essential.

The creation of a reliable seven segment display is a precise operation. For LED types, the process involves mounting tiny LED dice onto a lead frame or PCB substrate. These are then wire-bonded and encapsulated in a colored epoxy mold.

The mold defines the segment shape and acts as a diffuser. The contrast between lit and unlit segments is crucial for readability. Consistency in this encapsulation is a mark of quality.

LCD manufacturing is more complex. It starts with patterning transparent indium tin oxide (ITO) electrodes on two glass sheets. These sheets are assembled with spacers, sealed, and filled with liquid crystal material.

Polarizer films are laminated onto the outside surfaces. For reflective types, a mirror layer is added behind the rear polarizer. Frontlights or LED backlights are added as separate assemblies. Precision in cell gap and alignment is vital for uniform appearance.

The seven segment display is a testament to functional, enduring design. It solves the problem of numeric data presentation with unmatched efficiency. As technologies like LEDs and LCDs advance, this classic format continues to adapt and thrive.

Understanding the differences between display types, their ideal applications, and the sourcing landscape empowers better design decisions. For engineers and procurement specialists, collaborating with an experienced manufacturer such as Chuanhang Display can streamline the path from concept to a reliable, readable end product.

Q1: How many pins does a standard single-digit seven segment display have?

A1: A typical single-digit unit with a decimal point has 10 pins. These consist of one common pin (anode or cathode) for all segments, seven pins for the individual segments (a-g), one for the decimal point, and sometimes an extra common pin for the decimal point or as a structural ground.

Q2: Can I make a seven segment display show the letter 'A'?

A2: Yes, but within limits. By lighting segments a, b, c, e, f, and g, you can create a recognizable uppercase 'A'. This technique is often used to display hexadecimal values (0-9, A-F) or simple status codes. It is not designed for full text.

Q3: What is multiplexing in multi-digit displays?

A3: Multiplexing is a technique to control many digits with fewer driver pins. Instead of powering all digits continuously, the controller illuminates only one digit at a time. It cycles through the digits very rapidly. The human eye perceives this as all digits being lit simultaneously due to persistence of vision.

Q4: Why would I choose an LCD version over a brighter LED?

A4: The primary reasons are power consumption and sunlight readability. If your device is battery-powered and used in daylight, an LCD is likely the optimal choice. It uses minuscule current and relies on ambient light, making it clearly visible even in direct sun where an LED might wash out.

Q5: How long do these displays typically last?

A5: Lifespan depends heavily on the technology. LED displays often have rated lifespans exceeding 50,000 to 100,000 hours. LCD panels themselves can last for decades, but their backlights (if used) may have a shorter lifespan, typically around 20,000 to 50,000 hours for LEDs. Proper drive current and environmental protection are key to reaching these lifetimes.