When you're building an interface for a device, few components are as fundamental and reliable as the character LCD. For decades, these workhorses of the display world have been the go-to solution for presenting clear, alphanumeric information without the complexity or cost of a full graphical screen. Whether you're a hobbyist tinkering with an Arduino or an engineer designing industrial control panels, understanding the nuances of character LCD technology is crucial. This article cuts through the noise to give you the seven most important factors to consider for your next project, helping you make an informed choice between standard offerings and a custom character LCD.

Before diving in, let's clarify the basics. A character LCD is a dot-matrix liquid crystal display designed specifically to show letters, numbers, and a fixed set of symbols. Unlike their graphical cousins, they have a built-in controller (like the ubiquitous HD44780) that manages a predefined grid of characters, typically 5x8 pixels each. The most common formats you'll encounter are 16x2 (16 characters, 2 rows) and 20x4 (20 characters, 4 rows). Their simplicity, low power consumption, and ease of integration make them a perennial favorite across countless applications.

In an age of high-resolution OLEDs and full-color TFTs, you might wonder if the character LCD is obsolete. The answer is a resounding no. Their continued relevance stems from several key advantages:

Cost-Effectiveness: For applications that only need to display text, a character LCD is significantly cheaper than a graphical display, both in unit cost and the processing power required to drive it.

Simplicity of Integration: With a well-documented parallel or I2C/SPI interface, getting a "Hello, World" message to appear is often a matter of a few lines of code. This reduces development time and complexity.

High Readability: The high-contrast pixels (usually blue or green on a gray background) are easy to read in various lighting conditions.

Proven Reliability: This is a mature technology. The manufacturing processes are refined, leading to highly reliable and long-lasting components, a critical factor for industrial and medical equipment.

Not all character displays are created equal. When selecting one, pay close attention to these specifications:

Viewing Angle (6 o'clock or 12 o'clock): This indicates the optimal vertical direction from which the screen is clearest. A 6 o'clock angle is best viewed from below, while a 12 o'clock angle is best viewed from above.

Backlight Type and Color: The most common backlights are LED-based. Yellow-Green on a gray background is classic, but Blue/White on a blue background is extremely popular for its modern look. Consider the aesthetic and readability requirements of your end product.

Interface: The standard is an 8-bit or 4-bit parallel interface. However, modules with I2C or SPI adapters are widely available, saving precious GPIO pins on your microcontroller.

Operating Temperature Range: For consumer electronics, a standard range is sufficient. For automotive, industrial, or outdoor applications, you will need an extended temperature range character LCD.

This is where the real power for product developers lies. While off-the-shelf 16x2 displays are everywhere, what if your product needs a specific size, a unique set of custom characters, or a branded look? This is the domain of the custom character LCD.

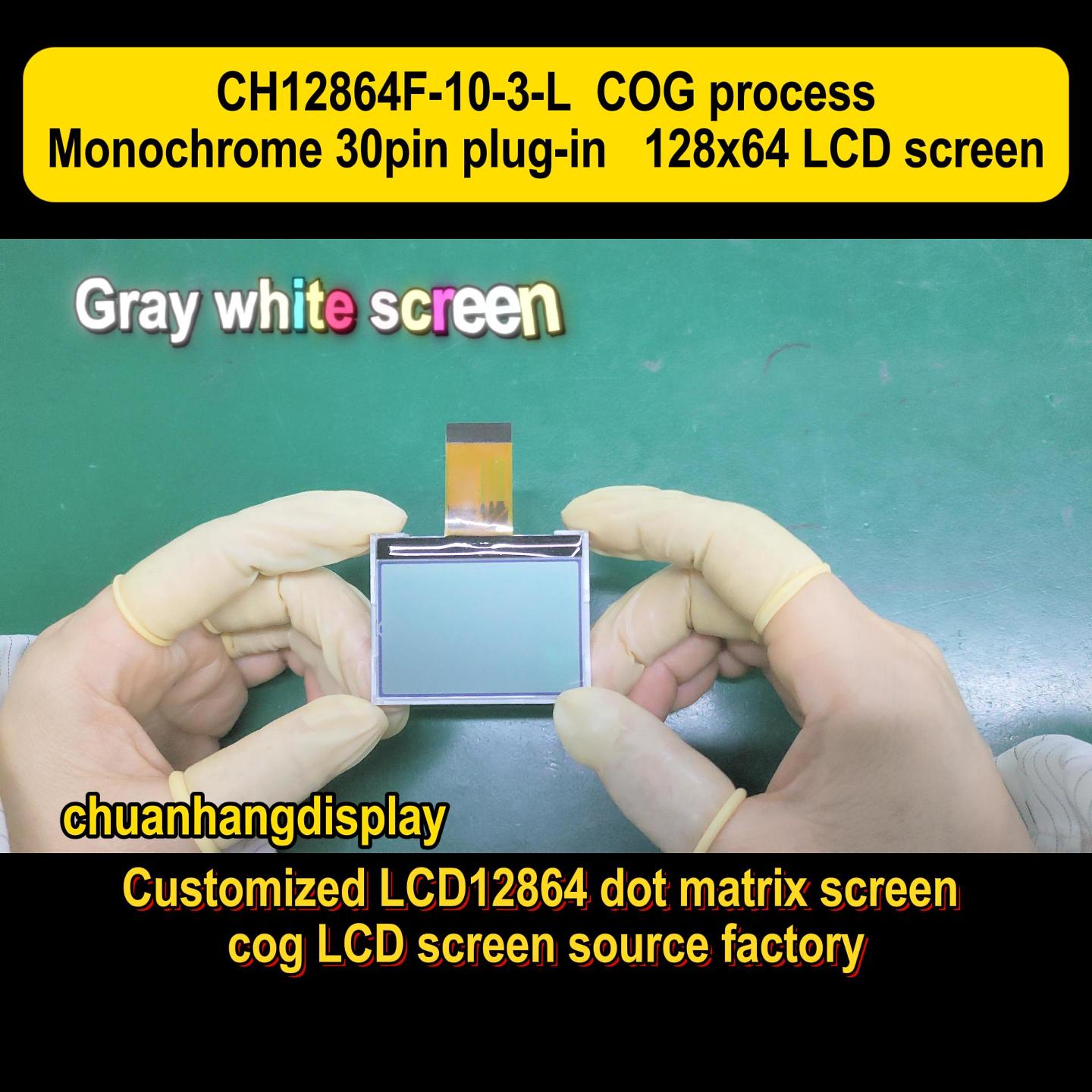

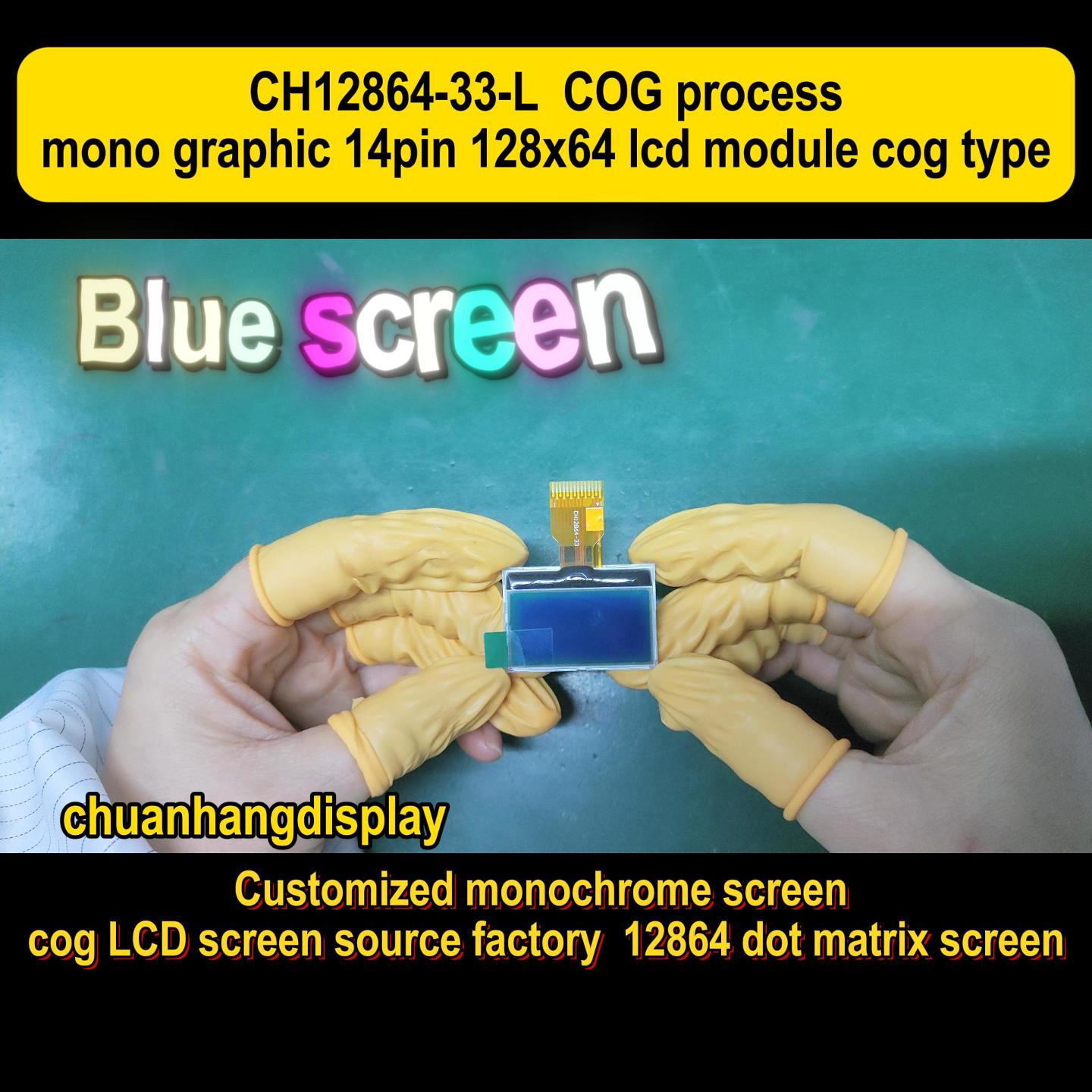

Companies like Chuanhang Display specialize in working with engineers to create tailored solutions. Customization can include:

Non-Standard Dimensions: Need a 24x1 display for a narrow panel or a 40x2 for a wide terminal? This is possible through customization.

Integrated Features: You can have the glass fitted with a resistive touchscreen, a protective plastic cover, or an anti-glare treatment.

Branding and Filter: Add a permanent logo, specific text, or a color filter to the polarizer to match your product's branding.

Specialized Connectors and Pinouts: Modify the physical interface to perfectly fit your PCB design.

Investing in a custom character LCD can elevate your product from a generic prototype to a polished, professional device.

The choice between these two technologies boils down to your project's needs.

Choose a Character LCD if: Your display is purely text-based (menus, readings, status messages), your budget is tight, your processor is low-power, and you need a quick, simple integration.

Choose a Graphical LCD (or TFT) if: You need to display images, complex shapes, dynamic graphics, or multiple fonts and languages. The trade-off is higher cost, more complex programming, and greater power consumption.

The quality of a character LCD is determined by its manufacturing process. It begins with the creation of the glass substrate, where the ITO (Indium Tin Oxide) electrodes are patterned to form the segments for each character. The alignment layer is rubbed to orient the liquid crystals, which is crucial for consistent contrast. The assembly and filling process must be pristine, as any contamination can lead to dead pixels or shortened lifespan. Finally, the polarizers are applied, and the module is assembled with the controller PCB and backlight. Reputable manufacturers like Chuanhang Display adhere to strict quality control throughout this process to ensure high yield and reliability.

Finding a supplier is easy; finding a reliable partner is harder. When sourcing character LCDs, especially in volume or for custom designs, look for a supplier with:

Proven Engineering Support: Can they answer technical questions and help solve integration issues?

Flexible Manufacturing Capabilities: Do they offer low minimum order quantities (MOQs) for custom character LCD projects?

Consistent Quality: Ask for samples and check their quality control certifications.

Supply Chain Stability: A supplier with a robust supply chain can prevent production delays.

The price of a standard character LCD is incredibly low, often just a few dollars per unit in volume. However, cost drivers include:

Volume: Unit price drops significantly with higher quantities.

Customization: A custom character LCD will have NRE (Non-Recurring Engineering) costs for the initial tooling and design, but the per-unit cost becomes competitive at volume.

Special Features: Extended temperature range, wide viewing angles, or integrated touch will add to the cost.

It's a balance. For a one-off project, a standard module from a distributor is fine. For a product you're manufacturing at scale, partnering directly with a manufacturer like Chuanhang Display to create a custom solution can be the most cost-effective and brand-enhancing path in the long run.

Q1: What is the difference between a positive and negative display on a character LCD?

A1: A positive display shows dark characters (e.g., blue or black) on a light background (e.g., white or gray), which is generally easier to read. A negative display shows light characters (e.g., white) on a dark background (e.g., blue or black). The choice is often aesthetic, though positive displays can offer slightly better readability in bright conditions.

Q2: Can I create my own symbols or characters on a standard character LCD?

A2: Yes. Most character LCD controllers allow you to define up to 8 custom characters (5x8 pixels) by programming the corresponding CGRAM (Character Generator RAM). This is perfect for simple logos, special symbols, or small icons.

Q3: How long is the typical lifespan of a character LCD?

A3: Character LCDs have a very long lifespan, typically rated at 50,000 to 100,000 hours. The backlight LEDs are usually the first component to fail, but even they last for tens of thousands of hours.

Q4: My character LCD has missing segments or all segments are visible. What is wrong?

A4: Missing segments are often a sign of a poor connection between the glass and the driver PCB, which can sometimes be fixed by reseating the zebra strip connector. If all segments are on, it usually indicates a problem with the contrast voltage (V0/VEE). Adjust the potentiometer controlling the contrast, as it may be set too high or too low.

Q5: I need a character LCD with a very specific outline and mounting holes. Is this possible?

A5: Absolutely. This is a common request for custom character LCD projects. Manufacturers can create modules with custom cutouts, specific PCB shapes, and mounting hole patterns to fit your enclosure perfectly. Providing a detailed mechanical drawing to your supplier, like Chuanhang Display, is the first step in this process.