In the world of compact electronics, where every pixel and milliampere counts, the OLED display 128x64 has emerged as an undisputed champion. This specific resolution and technology combination has become the go-to interface for a vast array of devices, from DIY maker projects to sophisticated commercial products. Its blend of crisp visibility, low power consumption, and a compact form factor makes it incredibly versatile. For engineers, designers, and product managers sourcing components, understanding the capabilities, applications, and sourcing options for this display is crucial. This article dives deep into the world of the 128x64 OLED display, with a focus on the robust solutions offered by industry leaders like Chuanhang Display.

Let's break down the core technology. A 128x64 OLED display is a flat panel display that utilizes Organic Light-Emitting Diodes (OLED). The "128x64" denotes its resolution: 128 pixels horizontally and 64 pixels vertically, resulting in a total of 8,192 individually controllable pixels.

Unlike traditional LCDs that require a backlight, each pixel in an OLED display is a tiny light source that emits its own light when an electric current passes through it. This fundamental difference unlocks several key advantages:

Superior Contrast and True Blacks: Since black pixels are simply turned off, OLEDs achieve an infinite contrast ratio, making images and text appear sharp and vibrant.

Wide Viewing Angles: The image quality remains consistent even when viewed from extreme angles, a significant advantage over many LCDs.

Fast Response Time: The near-instantaneous pixel response makes OLED displays ideal for applications involving fast-moving graphics or animation.

Thin and Lightweight Profile: The lack of a backlight unit allows for remarkably thin and flexible display constructions.

The OLED 128x64 module typically integrates the OLED panel, a driver IC (commonly the SSD1306 or SH1106), and a controller board, providing a ready-to-use interface for microcontrollers like Arduino, ESP32, and STM32.

The 128x64 OLED isn't popular by accident. Its resolution strikes a perfect balance between information density and physical size. It's sufficient to display a handful of lines of text, basic graphics, icons, and data visualizations without becoming overly complex or power-hungry. This makes the 128x64 pixel OLED the ideal choice for:

Consumer Electronics: Smartwatch interfaces, portable audio players, and handheld gaming devices.

Industrial Equipment: Parameter readouts on sensors, control panels for machinery, and diagnostic tools.

Medical Devices: Portable monitors for vital signs, readouts on infusion pumps, and handheld diagnostic equipment.

Automotive Aftermarket: Display units for car audio systems, tire pressure monitoring systems (TPMS), and OBD-II scanners.

DIY and Maker Projects: The backbone of countless Arduino and Raspberry Pi projects, from weather stations to mini game consoles.

Not all OLED display 128x64 units are created equal. When selecting one for your project or product, consider these critical parameters:

Controller Chip: The most common drivers are the SSD1306 and SH1106. The SSD1306 supports a full memory mapping of the 128x64 pixels, while the SH1106 uses a slightly different memory management method. Most libraries support both, but compatibility should be verified.

Interface: 128x64 OLED modules are available with different communication interfaces:

I2C: Uses only two data pins, saving valuable microcontroller I/O. Ideal for simpler projects.

SPI: Offers faster data transfer rates, suitable for applications requiring rapid screen updates.

Color Options: While monochrome (white, blue, or yellow-blue) is standard, there are also two-color versions (e.g., yellow on top, blue on bottom) that can be used to highlight different sections of the display.

Viewable Area and Dimensions: The physical size of the active display area and the overall module dimensions must fit your mechanical design.

Operating Temperature Range: For industrial or automotive applications, ensure the display is rated for the required temperature extremes.

Supplier Reliability and Support: Partnering with an established manufacturer like Chuanhang Display ensures consistent quality, reliable supply chains, and access to technical documentation.

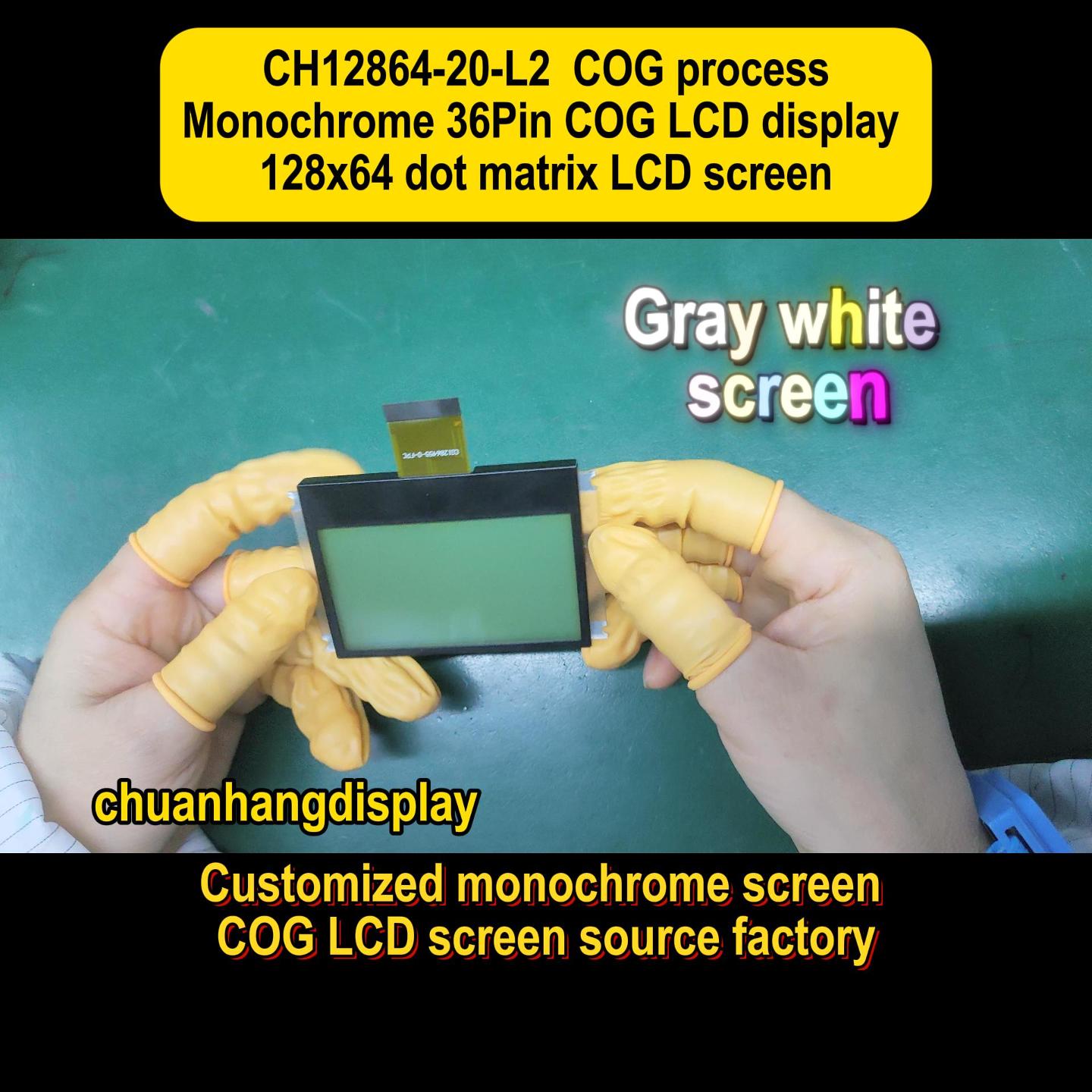

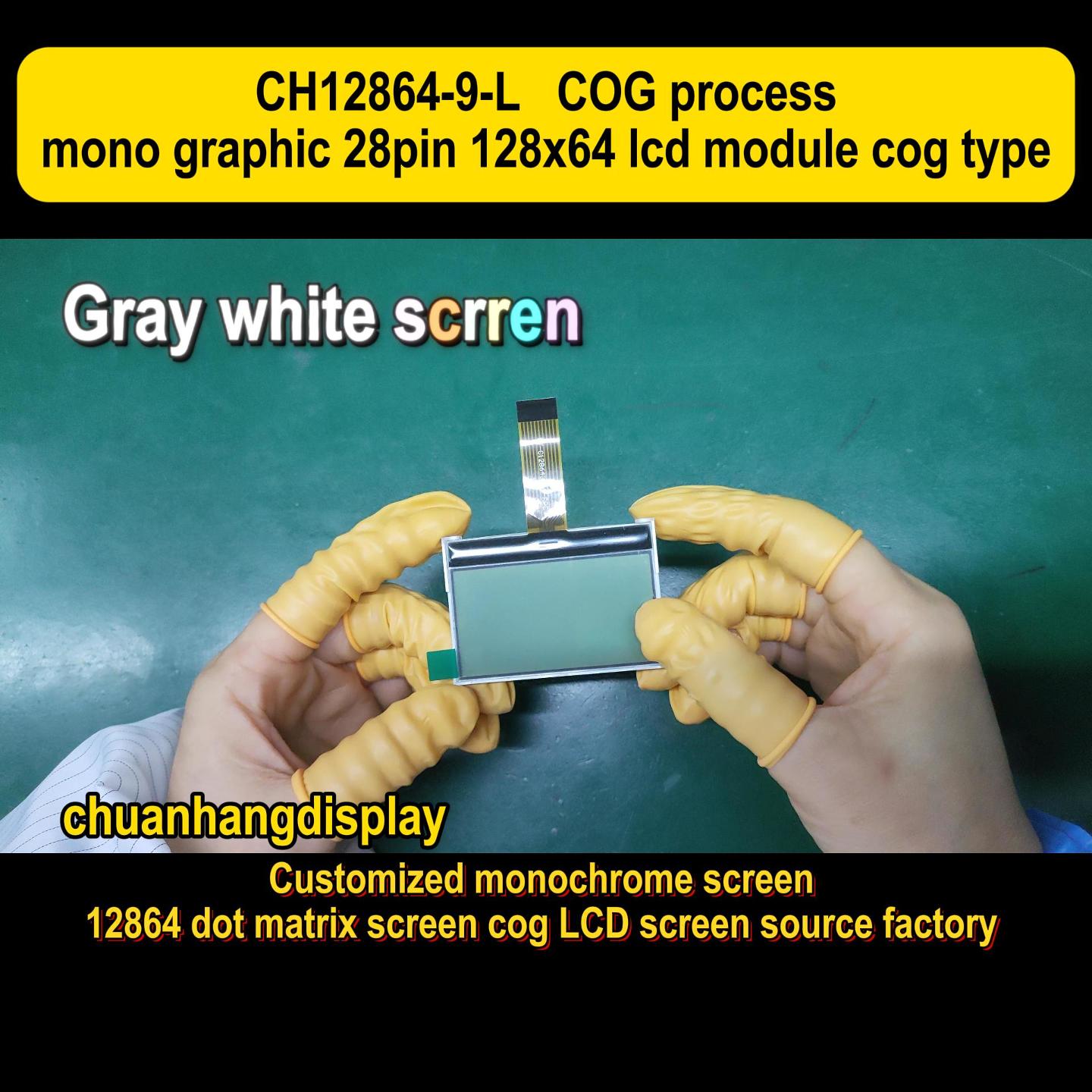

While standard OLED 128x64 modules are widely available, the true potential for product differentiation is unlocked through customization. Chuanhang Display, as a professional display manufacturer, specializes in providing custom OLED display 128x64 solutions tailored to specific client needs.

What does a custom OLED display entail?

Modified Form Factor: Altering the outline, tab placements, or the overall shape of the module to fit a unique enclosure.

Integrated Touch Functionality: Adding resistive or capacitive touch panels to create interactive interfaces.

Specialized Optical Bonding: Laminating the OLED to the cover glass to reduce reflections, enhance durability, and improve sunlight readability.

Extended Temperature Range: Engineering displays to perform reliably in harsh environments, from freezing cold to intense heat.

Customized Firmware and Controller Boards: Developing tailored driver solutions for specific main processors or operating systems.

By opting for a custom 128x64 OLED from a partner like Chuanhang Display, companies can create a product that is not only functional but also uniquely their own, protected from the commoditization that comes with off-the-shelf components.

When deciding on a display technology, it's essential to compare OLED with its primary competitor, the LCD.

| Feature | 128x64 OLED Display | Character/Graphic LCD |

|---|---|---|

| Contrast Ratio | Extremely High (Infinite) | Low to Medium |

| Viewing Angles | Wide (> 170°) | Narrow |

| Power Consumption | Low (pixels are self-emissive) | Higher (requires constant backlight) |

| Readability in Dark | Excellent | Good (requires dimmable backlight) |

| Response Time | Microseconds (µs) | Milliseconds (ms) |

| Temperature Range | Standard / Extended | Wide |

| Cost | Higher | Lower |

For applications where image quality, low power, and a slim profile are paramount, the OLED display 128x64 is the superior choice. For cost-sensitive applications where basic alphanumeric information is sufficient, an LCD might be adequate.

For businesses integrating OLED display 128x64 modules into their products, the choice of supplier is a strategic decision. Chuanhang Display represents the kind of supplier that offers more than just components. They provide:

Technical Expertise: In-depth support for interface integration and troubleshooting.

Consistent Quality Control: Ensuring every display meets rigorous performance standards.

Supply Chain Stability: Reliable production capacity and on-time delivery.

Customization Engineeing: A collaborative approach to developing bespoke OLED 128x64 solutions.

Engaging with a manufacturer early in the design process can streamline development, mitigate risks, and ultimately lead to a better, more competitive end product.

Q1: What is the difference between the SSD1306 and SH1106 driver chips for the 128x64 OLED?

A1: The primary difference lies in how they manage display memory. The SSD1306 has a full 1KB of RAM dedicated to the 128x64 bits (1024 bytes), mapping directly to the pixels. The SH1106 has 1KB of RAM but uses a 132x64 memory map. This means libraries must handle a small horizontal offset. In practice, both are well-supported, but it's crucial to use the correct library for your specific driver chip to avoid display issues.

Q2: How long is the typical lifespan of a 128x64 OLED display, and does it suffer from burn-in?

A2: The typical lifespan of a 128x64 OLED display is around 10,000 to 50,000 hours to half-brightness, depending on operating conditions. Like all OLEDs, it is susceptible to burn-in if a static image is displayed for a very prolonged period. To mitigate this, implementing features like screen savers, pixel shifting, or periodically dimming the display in firmware is recommended for applications with static UI elements.

Q3: Can I use a 128x64 OLED display in direct sunlight?

A3: Standard monochrome OLED 128x64 displays can be difficult to read in direct sunlight due to their emissive nature and reflection. For sunlight-readable applications, manufacturers like Chuanhang Display offer solutions with high-brightness panels (exceeding 1000 nits) and optical bonding. Optical bonding fills the air gap between the OLED and the cover glass with a resin, dramatically reducing reflections and improving contrast in bright ambient light.

Q4: What are the key steps involved in creating a custom OLED display with a supplier like Chuanhang Display?

A4: The process for a custom OLED display 128x64 typically involves: 1) Requirement Gathering: Defining your specs (dimensions, interface, temperature range, special features). 2) Feasibility Study & Quotation: The manufacturer assesses feasibility and provides a quote and timeline. 3) Engineering Sample (EVT): Creating and testing initial prototypes. 4) Design Validation (DVT): Refining the design based on feedback. 5) Production Validation (PVT): A final pre-production run. 6) Mass Production (MP): Ramping up to full-scale manufacturing.

Q5: For a low-power battery-operated device, is an I2C or SPI interface better for a 128x64 OLED?

A5: For the absolute lowest power consumption in terms of MCU I/O usage, I2C is generally better as it only requires two signal lines. However, SPI is much faster at updating the entire screen. The choice depends on your application's priority. If you update the screen infrequently (e.g., a sensor reading every few seconds), I2C is ideal. If you need to animate graphics or update data rapidly, SPI is worth the extra pins and marginally higher power draw during active communication.