Visual clarity often defines the user experience of a product. Whether it is a handheld medical device, a smart home thermostat, or an industrial control panel, the display is the primary interface. For years, LCDs dominated this space due to low cost. However, the shift toward high-contrast, wide-viewing-angle interfaces has made oled screens the preferred choice for modern electronics.

Engineers and product managers usually know the benefits: perfect blacks and vibrant colors. But selecting the right module involves more than just aesthetics. It requires a deep dive into drive methods, interface compatibility, lifespan management, and supply chain stability.

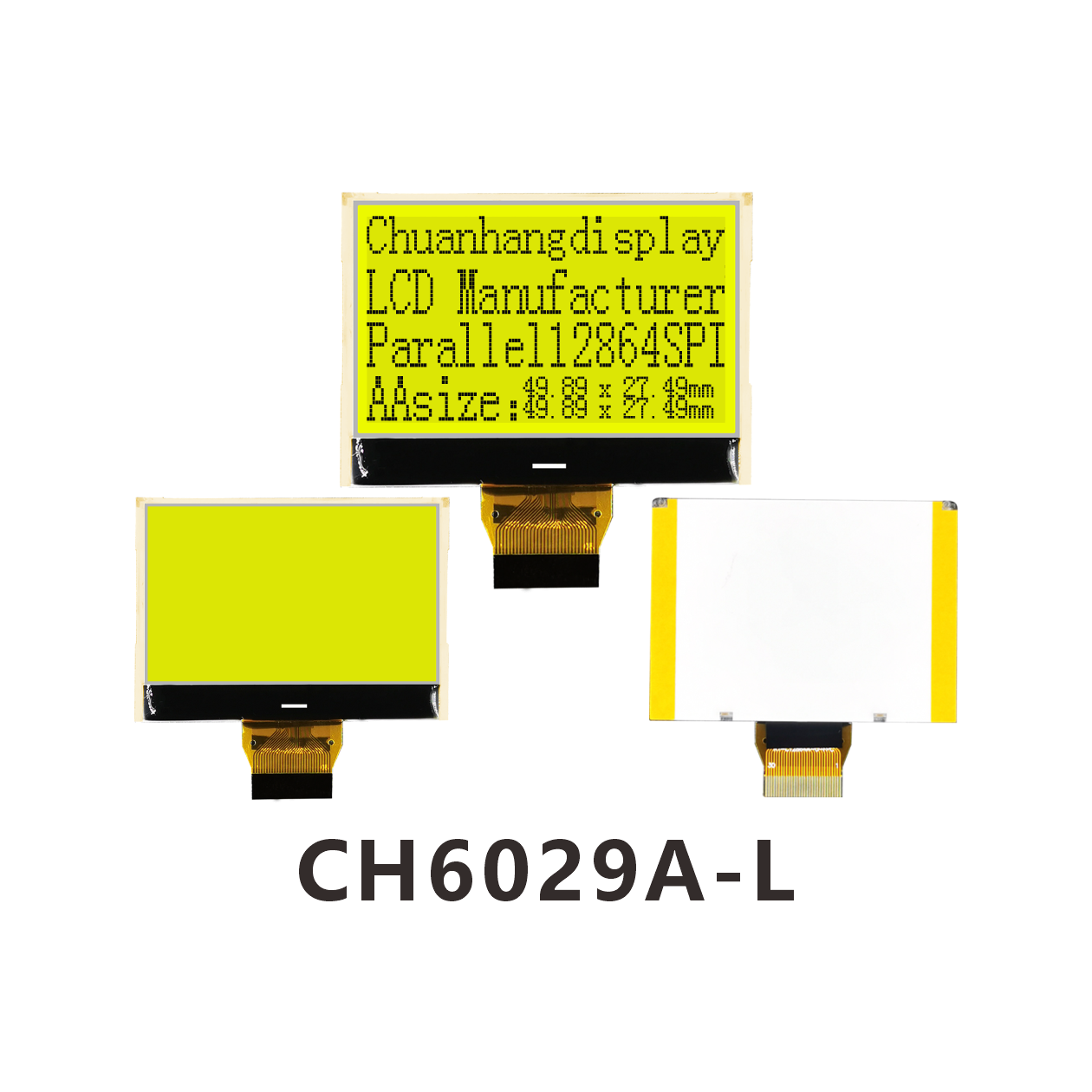

Chuanhang Display has supported countless projects making this transition. We understand that moving from a segment LCD or a standard TFT to an organic light-emitting diode requires a clear understanding of the trade-offs between cost, longevity, and performance. This article looks at the practical realities of sourcing and integrating this technology.

The fundamental difference between an OLED and an LCD is the light source. LCDs are transmissive; they block light from a backlight. OLEDs are emissive; each pixel generates its own light. This architecture eliminates the need for a bulky backlight unit.

The result is a display that is significantly thinner and lighter. For wearable devices or compact instrumentation, this space-saving attribute is critical. You can design slimmer enclosures or use the saved space for larger batteries.

Viewing angles are another major win. Traditional twisted nematic (TN) LCDs suffer from color inversion when viewed from the side. Oled screens maintain color accuracy and legibility from almost 170 degrees. In an industrial setting, where an operator might glance at a machine from an acute angle, this readability is a safety feature, not just a luxury.

Not all organic displays are built the same. The market is split into two main categories: Passive Matrix (PMOLED) and Active Matrix (AMOLED). Understanding the distinction is vital for your budget and power power.

PMOLED is generally used for smaller displays, typically under 3 inches. It uses a simple grid control scheme to light up pixels. It is cost-effective to manufacture and easy to drive with standard microcontrollers. If you are building a fitness tracker or a smart meter, PMOLED is likely your target.

AMOLED uses a Thin Film Transistor (TFT) array to control each pixel individually. This allows for larger sizes, higher resolutions, and better power efficiency at high brightness levels. Smartphones and high-end automotive dashboards use this.

For most industrial and embedded applications, PMOLED remains the dominant choice due to lower NRE (Non-Recurring Engineering) costs and simpler interface requirements. Chuanhang Display offers a wide range of PMOLEDs specifically designed to replace older STN modules without requiring a complete system redesign.

The most common hesitation engineers have regarding oled screens is longevity. It is a valid concern. Organic materials degrade over time, and blue pixels tend to degrade faster than red or green ones. This differential aging can lead to color shifts or "burn-in" if static images are displayed for too long.

However, material science has improved drastically. Modern industrial-grade OLEDs are rated for 30,000 to 50,000 hours of operation. This is comparable to many backlights used in budget TFTs.

Software strategies can further mitigate risks. Pixel shifting, where the image moves slightly every few minutes, is a common technique. Auto-dimming when the device is idle also preserves the organic layers.

When sourcing from Chuanhang Display, we can advise on the specific material sets used in manufacturing. We prioritize stability for industrial clients over the absolute peak brightness pushed by consumer smartphone manufacturers.

Integrating a new display into a PCB design requires matching the interface. Most small oled screens utilize serial interfaces to keep the pin count low. I2C and SPI are the industry standards for PMOLEDs.

I2C is popular because it requires only two data lines (SDA and SCL). This simplifies board routing and frees up GPIO pins on the main processor. However, it is slower than SPI.

SPI (Serial Peripheral Interface) is faster and better suited for displays that need to update graphics or animations quickly. For larger AMOLED units, you will often encounter MIPI DSI interfaces, which require more powerful processors and complex drivers.

The connection type is also a physical consideration. Most modules use a Flexible Printed Circuit (FPC) with a connector or a hot-bar soldering method. We often customize the FPC length and shape for our clients to ensure it fits perfectly inside their mechanical housing.

Pricing for oled screens is influenced by yield rates and raw material availability. The encapsulation process, which seals the organic material between glass to protect it from moisture, is technically demanding.

Glass-to-glass encapsulation creates a hermetic seal but adds thickness. Thin-film encapsulation is used for flexible displays but is more expensive. The yield rate—how many perfect screens come out of a production run—heavily dictates the final unit price.

In recent years, the supply chain for OLED driver ICs has been tight. A shortage in drivers can spike prices even if the panel production is stable. Working with a supplier like Chuanhang Display helps buffer these market shocks. We maintain strategic stock levels of popular sizes (like 0.91", 0.96", and 1.3") to ensure our clients do not face line-down situations.

Off-the-shelf components do not always meet the requirements of a specialized product. Customization is a key service in the display sector. This goes beyond just changing the size of the glass.

Touch panels are a frequent addition. We can bond a Capacitive Touch Panel (CTP) directly to the OLED. Because OLEDs are low-noise compared to high-voltage LCD backlights, touch performance is often excellent.

Cover glass customization is another option. For outdoor equipment, we can apply anti-glare (AG) or anti-reflective (AR) coatings. For medical devices, we can modify the cover lens to be antimicrobial or resistant to harsh cleaning chemicals.

Even the FPC can be redesigned. If your mainboard connector is located in an awkward spot, a custom FPC shape can save you from needing expensive board-to-board cables or redesigning your PCB.

Marketing materials often claim OLEDs are low power. This is true, but with a caveat. Because they are emissive, power consumption depends on what is being displayed.

An all-white screen draws maximum current. A screen that is 70% black draws very little. This is different from an LCD, where the backlight draws constant power regardless of the image.

Designers should take advantage of this. Using "Dark Mode" user interfaces is not just a style choice; it is a power-saving strategy. Text-heavy interfaces with black backgrounds are the sweet spot for oled screens.

Chuanhang Display engineers often help clients calculate their power budget based on typical GUI usage patterns. This ensures that the battery life estimates are accurate for the final product.

The market is flooded with low-grade panels, often rejected from Tier-1 production lines. These "B-grade" panels might look fine initially but will fail prematurely or exhibit uneven brightness.

Visual inspection alone cannot catch all defects. Micro-cracks in the sealing glass allow moisture to seep in over weeks, eventually killing the pixels. This manifests as "black spots" that grow over time.

Securing a reliable partner involves checking their Quality Control (QC) processes. Do they perform high-temperature, high-humidity storage tests? do they check for differential aging?

Chuanhang Display adheres to strict sorting processes. We ensure that the panels delivered to industrial clients meet the rigorous standards required for automotive, medical, and instrumentation use. We filter out the unstable stock that often ends up on generic marketplaces.

The transition to organic displays represents a significant upgrade in product quality. The deep blacks and crisp contrast of oled screens elevate the perceived value of any device. They offer functional benefits in viewing angles and response times that LCDs simply cannot match.

However, success lies in the details. It requires selecting the right matrix type (PMOLED vs. AMOLED), managing software to prevent burn-in, and securing a supply chain that filters out lower-grade fallout.

Cost is no longer the prohibitive barrier it once was. As production capacity increases globally, the price gap between high-end LCDs and OLEDs is narrowing.

Chuanhang Display is committed to guiding you through this selection. From the initial datasheet review to mass production logistics, our team ensures your display works as brilliantly in the field as it does on the prototype bench.

Q1: Do oled screens work well in direct sunlight?

A1: Yes, but it depends on the brightness rating. Standard OLEDs are readable, but for direct sunlight, you need high-brightness modules. Because OLEDs have naturally high contrast (black is truly black), they often outperform LCDs in readability even at lower brightness levels, provided the cover glass has proper anti-reflective coatings.

Q2: What is the main cause of OLED failure?

A2: The primary enemy of organic displays is moisture and oxygen. If the encapsulation seal is breached, the organic material oxidizes, leading to black spots that grow over time. Physical impact cracking the glass seal is a common cause, which is why proper housing design is critical.

Q3: Can I use an OLED display in extreme temperatures?

A3: OLEDs actually perform better than LCDs in cold temperatures. LCD fluids can freeze or become sluggish below -20°C. OLEDs are solid-state and maintain fast response times even in freezing conditions. However, extremely high temperatures (above 80°C) can accelerate the degradation of the organic materials.

Q4: Is it difficult to switch from an LCD to an OLED in an existing design?

A4: It can be straightforward if the interface is compatible. Many PMOLEDs are designed to be "pin-compatible" or software-compatible with common character LCDs. However, you will need to adjust your initialization code and power supply circuits, as OLEDs require different voltage levels than LCD backlights.

Q5: What is the minimum order quantity (MOQ) for custom OLED modules from Chuanhang Display?

A5: We strive to be flexible. For standard off-the-shelf modules, MOQs are very low. For custom solutions involving unique FPC shapes or touch panels, the MOQ is typically higher to cover tooling and setup costs, but we work with growing businesses to find a workable volume.