If you’re designing a product, you’re probably considering an LCD display screen. They’re everywhere—from your microwave to your car’s dashboard to your smartphone.

But “LCD” covers a vast range of technologies and performance levels. Choosing the wrong one can lead to cost overruns, design delays, or a poor user experience.

This article cuts through the jargon. We’ll explain the core types, key selection factors, and practical advice for sourcing a reliable LCD display screen for your project.

LCD stands for Liquid Crystal Display. At its heart, an LCD display screen doesn’t produce its own light. It uses a backlight and manipulates liquid crystals to block or allow light to pass through, creating an image.

Think of the liquid crystals as tiny shutters. An electric current twists them, controlling how much light from the backlight passes through red, green, and blue color filters.

This fundamental principle allows for thin, energy-efficient, and highly reliable screens. The LCD module you buy includes the glass panel, the driver electronics, and often the backlight unit as one integrated component.

Not all LCDs are the same. The technology behind the panel defines its performance.

TN (Twisted Nematic): The most common and cost-effective type. A standard TN LCD display screen offers fast response times but has poor viewing angles and color reproduction. It’s fine for simple numeric readouts or basic interfaces viewed straight-on.

IPS (In-Plane Switching): Developed to solve the viewing angle problem. An IPS LCD screen delivers superior color accuracy and wide viewing angles (often up to 178 degrees). It’s the go-to choice for medical devices, point-of-sale systems, and any application where the screen might be viewed from the side.

VA (Vertical Alignment): A middle ground. VA LCD displays offer better contrast and color than TN, and better contrast than IPS, but with slower response times and less consistent viewing angles than IPS. Common in some industrial monitors.

Choosing a screen is about matching specs to your application’s real-world demands.

Size and Resolution: This defines the physical space and pixel density. A 7-inch LCD display screen with 800x480 resolution is common for HMIs. Higher resolution (1024x600 or 1920x1080) provides sharper text and graphics.

Brightness (Nits): Measured in candelas per square meter (nits). For indoor office use, 250-300 nits may suffice. For sunlight readability, you need 1000 nits or more. Don’t over-specify, as higher brightness increases cost and power consumption.

Viewing Angle: If your device will be viewed from above, below, or the side (like a car radio), an IPS LCD panel is almost always necessary.

Temperature Range: Commercial screens typically work from 0°C to 50°C. For industrial, automotive, or outdoor use, you need an extended range, such as -30°C to +80°C. This requires special materials and manufacturing processes.

Interface: This is how the screen talks to your main board. Common interfaces include LVDS (for high-resolution TFTs), RGB Parallel, MIPI-DSI (for compact mobile designs), and MCU (for simpler displays). Compatibility is critical.

Sometimes, an off-the-shelf LCD module doesn’t fit. That’s where customization comes in.

A custom LCD display screen involves modifying a standard panel to meet unique requirements. This can include:

Outline Customization: Changing the shape or size of the glass or the PCB.

Optical Bonding: Laminating a cover glass directly to the LCD panel with an optical adhesive. This eliminates an air gap, reducing reflections, improving sunlight readability, and making the screen more robust. It’s a common custom LCD screen service for harsh environments.

Special Touchscreens: Integrating a specific type of touch sensor (resistive, capacitive, or ruggedized projective capacitive) with a custom controller or firmware.

Special Connectors or Cables: Relocating the FPC connector or creating a custom cable harness to fit your board layout.

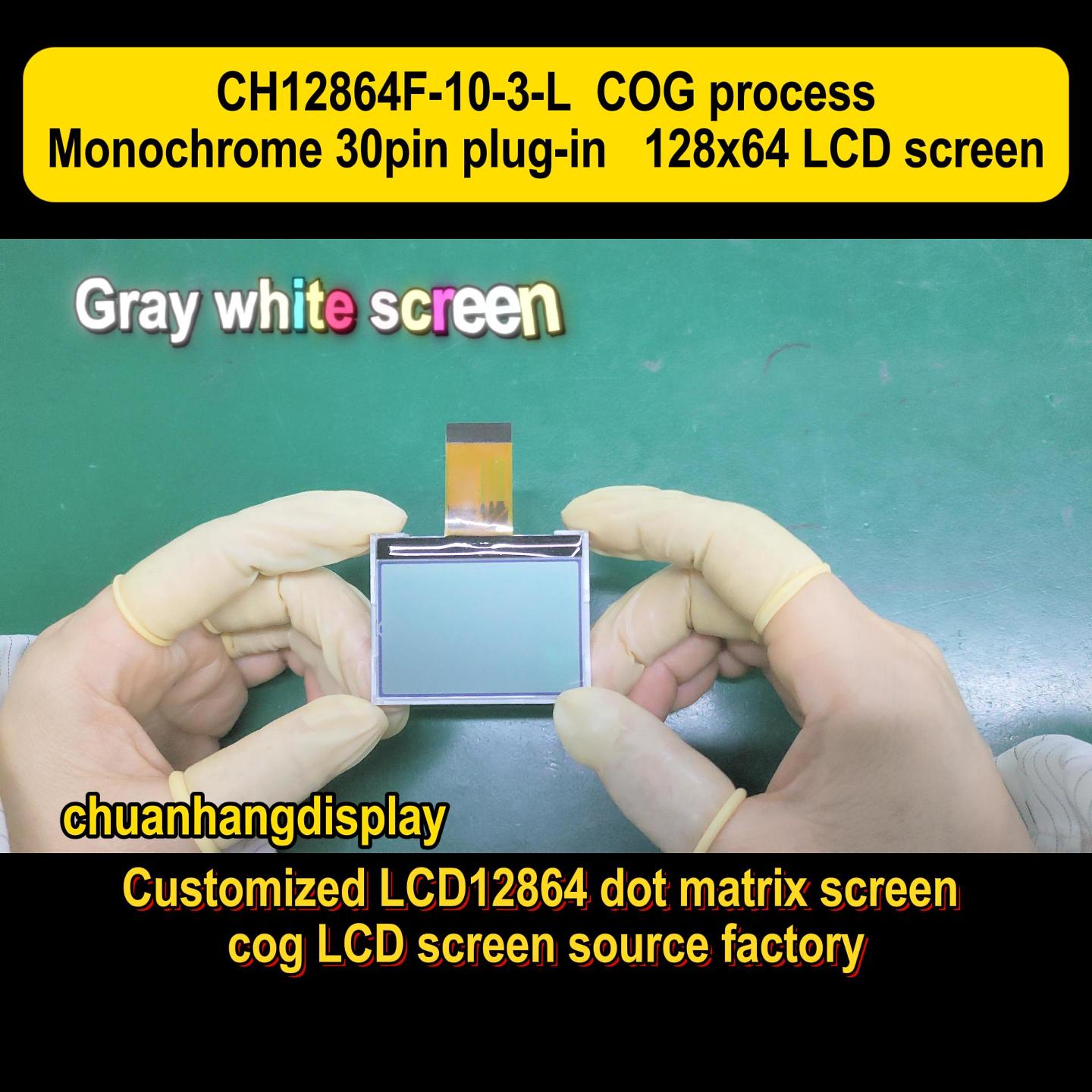

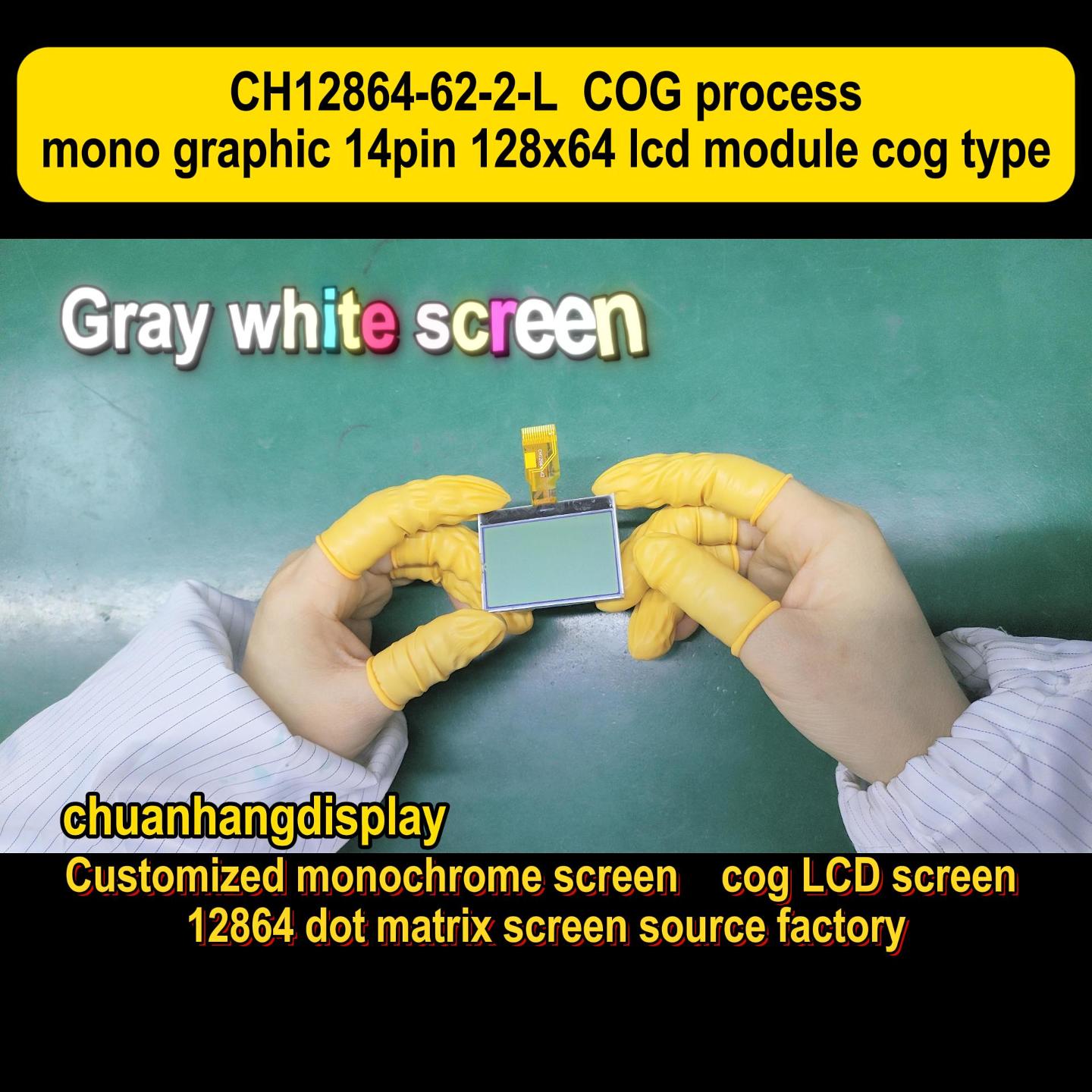

Companies like Chuanhang Display specialize in these custom LCD display adaptations, bridging the gap between a standard catalog part and a fully bespoke solution.

Understanding cost helps you make smart trade-offs.

Panel Technology: An IPS LCD screen costs more than a TN panel of the same size due to a more complex manufacturing process.

Brightness and Temperature Range: High-brightness LEDs and components rated for extreme temperatures increase the bill of materials.

Resolution: Higher resolution requires more precise manufacturing and more powerful driver ICs.

Customization: Any modification adds Non-Recurring Engineering (NRE) costs. However, for high-volume projects, a custom LCD display that perfectly fits your enclosure can save money by eliminating adapter brackets or secondary assembly steps.

Volume: Unit price drops dramatically with higher quantities. Prototype pricing is not indicative of mass production pricing.

Your LCD display screen supplier is a long-term partner. Reliability is paramount.

Technical Support: Can they provide detailed timing specifications, driver IC datasheets, and schematic review? A good supplier, such as Chuanhang Display, will have engineers who can answer technical questions.

Quality Control: Ask about their testing procedures. Do they perform 100% aging tests? How do they handle dead pixel criteria? Request samples to evaluate build quality.

Supply Chain Stability: A supplier with strong manufacturer relationships is less vulnerable to component shortages and can ensure stable long-term supply.

Customization Capability: If you anticipate needing a custom LCD solution, partner with a supplier that has in-house engineering and integration capabilities from the start.

For engineers and procurement managers, Chuanhang Display serves as a practical solutions provider. They focus on the industrial and embedded market, offering a range of standard LCD display screens from TFT to monochrome models.

Where they add significant value is in adaptation. Their expertise lies in taking a standard LCD panel and turning it into a custom LCD display screen ready for your application—whether that means optical bonding for outdoor use, a special touch interface, or a unique form factor.

This approach combines the cost-effectiveness of standard panels with the fit of a custom design. It avoids the long lead times and high costs of a completely ground-up display development.

Selecting the right LCD display screen is a balance of specification, cost, and partnership. Start by rigorously defining your must-have specs: size, brightness, viewing angle, and operating environment.

Use these to narrow down panel technology (IPS, TN, etc.). Then, factor in integration needs to decide if a standard module will work or if a custom LCD solution is justified.

Finally, choose a supplier based on technical competence and reliability, not just the lowest unit price. A dependable partner ensures your display is a component you never have to worry about.

Q1: What is the difference between an LCD panel and an LCD module?

A1: An LCD panel is just the glass sandwich with the liquid crystals—the core display element. An LCD module (or LCM) includes the panel, the driver circuitry (PCBs and chips), the backlight unit, and often a bezel. When you buy an LCD display screen for integration, you are almost always buying a complete module.

Q2: Can I integrate a touchscreen with any LCD display screen?

A2: In most cases, yes. Touchscreens (resistive or capacitive) are separate layers that are laminated onto the front of the LCD module. This is a standard service. You must ensure your chosen LCD supplier can provide a properly bonded and tested touch-integrated unit, as DIY bonding often leads to optical defects.

Q3: How long do LCD display screens typically last?

A3: The lifetime is primarily defined by the backlight LEDs. A quality industrial LCD display screen is typically rated for 50,000 hours or more (that’s over 5 years of continuous use). Panel longevity can be much longer. High-temperature operation will reduce this lifespan.

Q4: What is involved in getting a custom LCD display screen quote?

A4: You need to provide clear requirements: desired base panel specs (size, resolution, technology), and the exact modifications needed (outline drawings, bonding specs, connector type). Suppliers like Chuanhang Display will then assess feasibility, provide NRE costs for tooling/engineering, and a per-unit price based on your projected volume.

Q5: What is the minimum order quantity (MOQ) for a custom LCD screen?

A5: For a truly custom design (new glass mask), MOQs can be in the thousands. However, for modifications to a standard panel (like optical bonding or a custom FPC), MOQs can be much lower, sometimes in the hundreds. Always discuss volume expectations upfront with your supplier.