Sourcing the correct components for industrial electronics is a precise science. Engineers and procurement managers spend hours analyzing data sheets to ensure compatibility, longevity, and performance. If you have been searching for display modules, you have likely encountered JHD part numbers or specifications in your bill of materials.

Finding a direct replacement or an upgrade for these standard screens can be challenging. You need a supplier that understands the intricacies of liquid crystal technology. At Chuanhang Display, we specialize in manufacturing high-reliability display modules that meet or exceed the standards often associated with common market specifications.

This article details the critical aspects of selecting industrial displays. We will cover technical compatibility, the benefits of upgrading your supply chain, and why Chuanhang Display is the partner you need for your next production run.

In the world of Character and Graphic LCDs, certain form factors have become industry standards. When an engineer looks for a JHD style module, they are usually looking for specific dimensions and pinouts.

The most common requests are for the classic 16x2 character displays or the 128x64 graphic modules. These sizes fit into a vast array of existing enclosures, from server racks to handheld meters.

However, relying on a single part number from a general distributor can be risky. Specifications can vary slightly between batches. We focus on stabilizing these variables. Our engineering team analyzes the original footprint to ensure our modules act as a true drop-in replacement.

We ensure the mounting holes, active area, and viewing area match perfectly. This means you do not have to redesign your PCB or your plastic housing when switching to our solutions.

While a standard JHD screen might work for basic applications, industrial environments often demand better optical performance. The readability of a screen is determined by its contrast ratio and viewing angle.

Many generic displays use low-cost Twisted Nematic (TN) fluid. This results in a narrow viewing angle. If you look at the screen from the side, the characters might disappear or invert.

Chuanhang Display offers upgrades to Film Super-Twisted Nematic (FSTN) or Double FSTN (DFSTN) technologies. These materials provide a much sharper contrast. The background is darker, and the pixels are distinct, making the data readable from wider angles.

We also focus on the polarizer quality. Standard polarizers can degrade under UV exposure. We use industrial-grade polarizers that resist yellowing, ensuring the display remains clear for years, not just months.

A major pain point when replacing a JHD module is the electrical interface. Standard modules typically use a parallel interface, often requiring many GPIO pins on your microcontroller.

In modern designs, saving pins is crucial. We offer modules that maintain the physical size of the standard JHD models but utilize different communication protocols.

I2C and SPI OptionsWe can provide displays with I2C or SPI interfaces. These protocols require fewer wires, simplifying your circuit design and reducing the potential for electromagnetic interference (EMI).

Controller ICsCompatibility with the controller logic is non-negotiable. If your code is written for a standard Hitachi HD44780 or a Samsung KS0108, the replacement module must speak the same language. We verify that our controller ICs are fully compatible with your existing firmware. You should not have to rewrite thousands of lines of code just to change a display vendor.

One area where a stock JHD display often falls short is the backlight. Standard modules usually come with a basic yellow-green or white LED side-light.

At Chuanhang Display, we view the backlight as a critical component of the user experience. We allow for full customization of the LED array.

Brightness LevelsFor indoor equipment, 200 nits is sufficient. However, if your device is used outdoors, you need high brightness. We can build modules with custom LED rails that push brightness to 500 or even 1000 nits without changing the form factor.

Color OptionsWhile blue and white are popular, some industries require specific colors. For example, red backlights are often used in aviation or night-vision environments to preserve natural night sight. We can customize the LED color to match your brand identity or functional requirements.

A search for JHD equivalents often stems from a need for better durability. Consumer-grade screens cannot handle the rigors of an industrial floor.

Temperature RangesStandard displays operate between 0°C and 50°C. This is insufficient for automotive or outdoor use. Our "Wide Temperature" modules function reliably from -20°C to +70°C. We use specialized liquid crystal fluid that prevents the display from becoming sluggish in freezing temperatures.

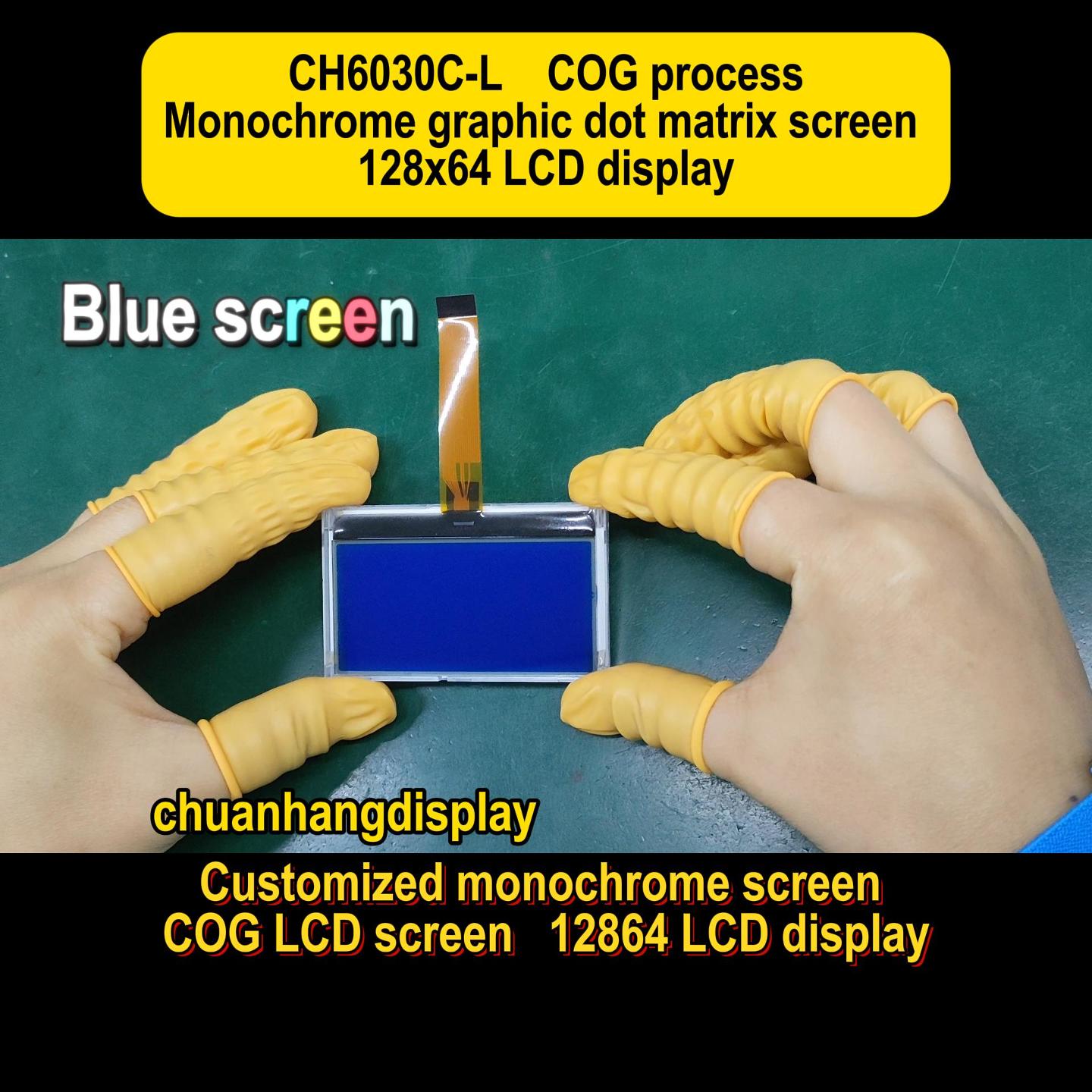

Vibration ResistanceEquipment like CNC machines or heavy trucks subjects components to constant vibration. We employ robust Chip-on-Board (COB) or Chip-on-Glass (COG) construction methods. We reinforce the bezel clips and the soldering of the backlight to ensure mechanical integrity.

The problem with searching for a specific JHD keyword on general marketplaces is the lack of support. You are often buying from a trader who knows nothing about the product.

Chuanhang Display is a manufacturer, not just a reseller. We control the process from the glass cutting to the final assembly. This vertical integration allows us to offer consistent quality control.

We perform 100% functional testing on every unit. This includes power-on aging tests to eliminate infant mortality. When you receive a tray of displays from us, you can be confident that every single one will work.

We also offer long-term availability. We understand that industrial products have life cycles of 5 to 10 years. We do not discontinue a model simply because consumer trends shift. We commit to supplying your specific configuration for the duration of your product's life.

Many legacy products use monochrome JHD style screens. However, the market is moving toward color. Migrating from a character LCD to a TFT LCD can be daunting.

We assist clients in this transition. We offer small-sized TFT modules (0.96 inch to 3.5 inch) that can fit into similar physical spaces as older monochrome screens.

These TFTs offer full color and higher resolution, allowing for more modern user interfaces. We can provide these with simplified interfaces like MCU 8080 or SPI, making it easier for your existing microcontroller to drive a color screen without needing a high-end processor.

When you encounter a timing issue or a ghosting effect on a JHD equivalent, you need answers immediately. Generic suppliers rarely offer technical insights.

Our team at Chuanhang Display is composed of engineers. We can help you debug initialization codes. We can advise on the best bias voltage settings to optimize contrast.

We can also help you design the mechanical integration. If the standard bezel hooks interfere with your casing, we can modify the metal frame. If the FPC cable is too short, we can design a custom cable to reach your connector.

Our displays are currently deployed in sectors that demand high reliability.

Medical DevicesIn healthcare, accuracy is vital. Our high-contrast displays are used in infusion pumps and portable diagnostic tools. The clarity of the segments ensures that medical professionals do not misread dosage numbers.

Energy MetersSmart meters require low power consumption. We supply transflective modules that are readable in sunlight without the backlight on, saving battery life. These units are built to withstand the heat inside outdoor utility boxes.

Industrial AutomationFactory HMI panels need to withstand dust and oil. We offer displays with bonded protective glass and touch screens that work even when the operator is wearing gloves.

The search for the perfect display often starts with a keyword like JHD, but it should end with a partnership with a reliable manufacturer. You need more than just a part number; you need a solution that fits your specific engineering constraints.

Chuanhang Display offers the technical expertise, manufacturing quality, and customization options that generic suppliers cannot match. whether you need a direct replacement for a legacy part or a custom design for a new product, we are ready to assist.

Do not settle for "good enough" when it comes to your user interface. Trust Chuanhang Display to deliver the visual performance your product deserves.

Q1: Can Chuanhang Display provide a direct drop-in replacement for a specific JHD part number?

A1: Yes, in most cases we can. We analyze the datasheet of the JHD module you are currently using to match the mechanical dimensions, pin definition, and electrical characteristics. If a direct match isn't available off-the-shelf, we can adjust our tooling to create one.

Q2: What is the difference between STN and FSTN technologies in your displays?

A2: STN (Super-Twisted Nematic) is a standard technology that offers decent contrast but often has a characteristic green or blue tint. FSTN (Film Super-Twisted Nematic) uses an additional retardation film to produce a black-and-white image with much higher contrast and wider viewing angles, making it superior for professional equipment.

Q3: Does Chuanhang Display offer custom FPC (Flexible Printed Circuit) cables?

A3: Absolutely. We understand that the connector position on your PCB is fixed. We can customize the length, shape, and pinout of the FPC cable on our LCD modules to ensure a perfect fit inside your device housing.

Q4: What are the lead times for custom LCD samples?

A4: Generally, creating a custom sample takes between 15 to 20 working days. This includes the time for drawing approval, tooling production, and sample manufacturing. Once approved, mass production lead times are typically around 4 to 5 weeks.

Q5: Can I request a specific viewing angle for my display?

A5: Yes. LCDs have a preferred viewing direction, usually described as 6 o'clock or 12 o'clock. If your device is mounted on a wall above eye level, you need a 6 o'clock viewing angle. If it is on a desk below eye level, you need 12 o'clock. We can manufacture the module with the bias angle optimized for your specific application.