In today's technologically driven world, the humble LCD character display remains a fundamental and reliable interface between machines and humans. These displays are ubiquitous, found in everything from industrial control panels and medical devices to point-of-sale systems and consumer electronics. While high-resolution touchscreens often grab the headlines, the simplicity, cost-effectiveness, and readability of character LCDs make them an indispensable component in countless applications. This article delves into the world of LCDs, exploring common types like the LCD 16x4 and 128x64 graphic LCD display, the role of an LCD module factory, and the advantages of partnering with a custom LCD display manufacturer, with a special focus on the expertise offered by Chuanhang Display.

An LCD character display is a type of liquid crystal display designed specifically to show alphanumeric characters, symbols, and limited custom graphics. Unlike graphical displays that control individual pixels, standard character LCDs use a built-in controller that manages a fixed set of predefined characters, typically based on the ASCII standard. This makes them incredibly easy to interface with microcontrollers like Arduino or Raspberry Pi, requiring only a few digital I/O pins to communicate and display text.

Their core advantages include:

Low Power Consumption: Ideal for battery-operated devices.

High Contrast: Excellent readability in various lighting conditions, especially when equipped with a backlight (LED or EL).

Cost-Effectiveness: Significantly cheaper than equivalent-sized graphical or touch displays.

Ease of Use: Simple command set for clearing the screen, moving the cursor, and sending data.

One of the most popular configurations in the industry is the LCD 16x4. This format provides a compact yet informative screen capable of displaying four lines of text, with each line holding up to 16 characters. This makes it perfect for applications that require more information than a classic 16x2 display can show without excessive scrolling.

Common Applications of 16x4 LCDs:

Industrial Equipment: Displaying machine status, parameters, and diagnostic messages.

Laboratory Instruments: Showing readings, settings, and calibration data.

Network Infrastructure: Providing status updates on routers, servers, and communication hardware.

Point-of-Sale (POS) Systems: Showing transaction details for cashiers and customers.

DIY Electronics Projects: A favorite among hobbyists for its balance of size and capability.

For manufacturers like Chuanhang Display, producing high-quality and reliable LCD 16x4 modules is a core competency. Their modules often feature adjustable backlights, wide operating temperature ranges, and robust construction to ensure longevity in demanding environments.

While character LCDs are perfect for text, many applications require the ability to draw shapes, logos, or detailed data graphs. This is where the 128x64 graphic LCD display comes into play. As the name suggests, this display has a resolution of 128 pixels horizontally and 64 pixels vertically. Each pixel can be individually controlled, offering immense flexibility.

The 128x64 graphic LCD display often includes a built-in controller, such as the ST7920 or KS0108, which handles the complex task of pixel management. While programming is more complex than sending simple text commands, it unlocks the potential for:

Custom User Interfaces: With icons and menus.

Data Visualization: Real-time plotting of sensor data, waveforms, and charts.

Bitmap Images: Displaying company logos or detailed symbols.

Multi-language Support: Displaying non-Western character sets like Chinese or Japanese.

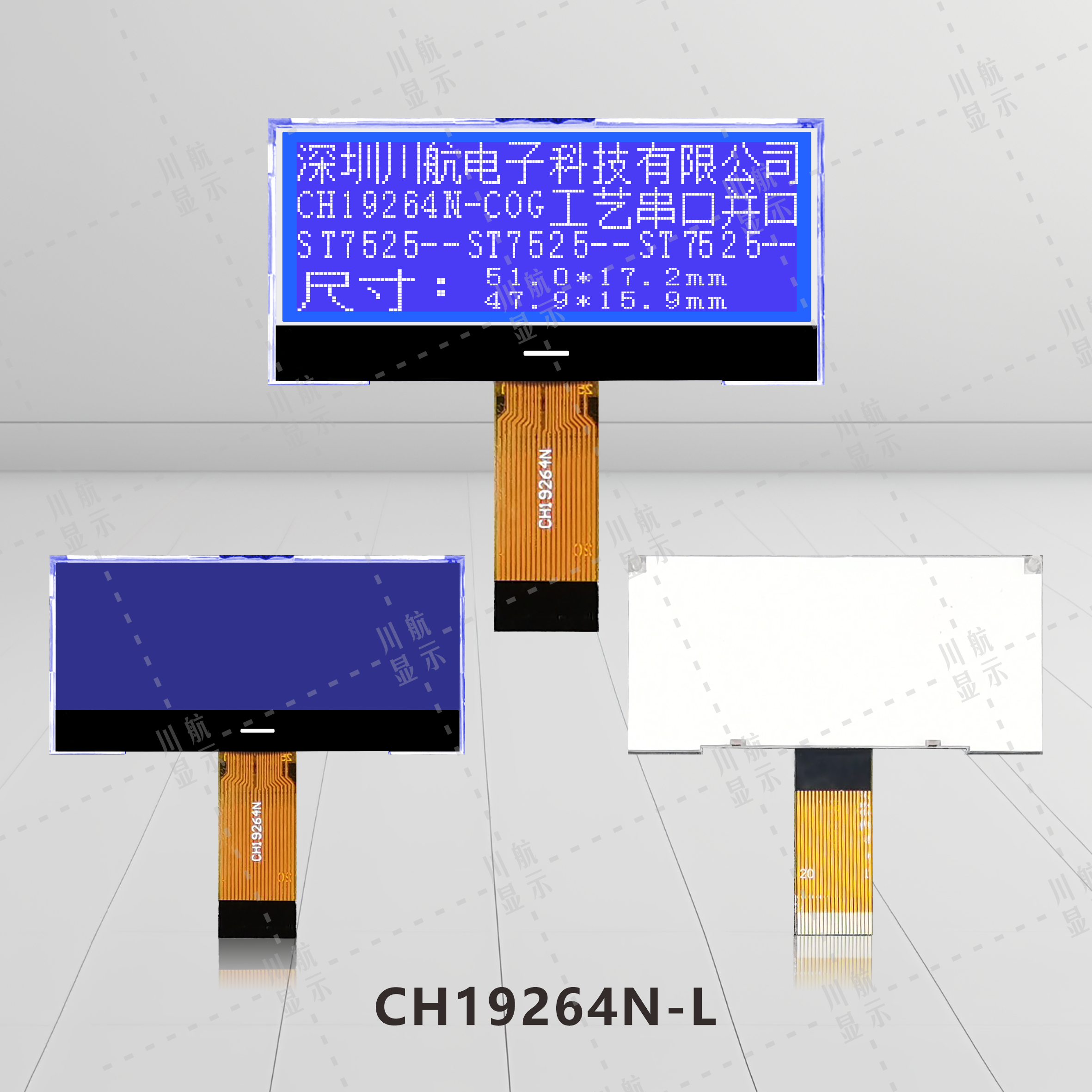

An experienced LCD module factory will produce both character and graphic modules, ensuring a consistent level of quality across their product lines. Chuanhang Display, for instance, offers a range of graphic LCDs with various interfaces (parallel, serial, I2C) to suit different project requirements.

The Role of an LCD Module Factory

An LCD module factory is the engine room where raw glass and components are transformed into finished, ready-to-use displays. The manufacturing process is precise and involves several critical steps:

Cell Assembly: Creating the liquid crystal "sandwich" between two layers of glass.

Polarizer Lamination: Applying polarizing films to the outer surfaces of the glass.

Backlight Integration: Adding LED light strips and a light guide plate for illumination.

Controller Bonding: Attaching the driver IC (Integrated Circuit) that controls the pixels or characters.

Testing: Rigorously testing each module for functionality, contrast, backlight uniformity, and dead pixels.

The expertise of a factory determines the quality and reliability of the end product. A reputable factory like Chuanhang Display invests in automated equipment, stringent quality control protocols, and engineering expertise to ensure every LCD character display that leaves its production line meets high standards.

Sometimes, an off-the-shelf LCD 16x4 or a standard 128x64 graphic LCD display won't meet the specific needs of a product. This is where partnering with a custom LCD display manufacturer becomes critical. Customization can range from simple modifications to completely bespoke designs.

What can a custom LCD display manufacturer like Chuanhang Display offer?

Size and Shape: Non-standard dimensions or cutouts to fit unique product designs.

Viewing Mode and Backlight Color: Transflective displays for sunlight readability, or specific backlight colors (e.g., red, blue, green, amber) to match a product's branding or indicate status.

Interface and Pinout: Customizing the communication protocol or connector pin arrangement to simplify integration into a main PCB.

Integrated Components: Adding a touch panel (resistive or capacitive) directly onto the display assembly or embedding a temperature sensor.

Branding: Printing logos, custom legends, or specific symbols directly onto the viewing area or the bezel.

Optical Bonding: Laminating the LCD to the cover glass to reduce glare and improve readability in high-ambient-light conditions.

Working with a manufacturer capable of customization allows product designers to innovate freely, creating a more cohesive and optimized end-user experience.

Even with their simplicity, users can encounter issues when integrating these displays. Here are some common problems and their solutions:

1. Display is Blank (No Characters Visible)

Cause: This is often a power issue. Check that the VCC and GND connections are correct and that the voltage is within the specified range (typically 5V or 3.3V). Also, check the contrast voltage (Vo pin); if it's too high or too low, the characters will not be visible.

Solution: Use a potentiometer to adjust the contrast pin until the characters appear. Double-check all wiring.

2. Display Shows Garbage Characters or Random Blocks

Cause: Incorrect initialization routine or improper data communication timing. The microcontroller might be sending data before the display's controller is ready.

Solution: Ensure your code includes the correct initialization sequence as specified in the datasheet. Add a delay after power-up before sending commands. Check that the data bus connections are secure.

3. Only the Backlight Works

Cause: The display is powered, but no data is being received. This could be due to a wiring fault on the data lines (D0-D7) or the control lines (RS, RW, E).

Solution: Verify the connections for the RS (Register Select) and E (Enable) pins. The RW (Read/Write) pin should typically be grounded for write mode.

4. Fading or Missing Segments in Characters

Cause: This can indicate a weak connection or a failing controller. In rare cases, it could be physical damage to the LCD glass.

Solution: Resolder the pins on the display module. If the problem persists, the module may need to be replaced.

5. Inconsistent Performance in Extreme Temperatures

Cause: Standard LCDs have a limited operating temperature range (usually 0°C to +50°C). The liquid crystal fluid can become viscous in cold weather, causing slow response, and may become isotropic in hot weather, causing the display to black out.

Solution: For applications outside the standard range, specify an extended-temperature display from your manufacturer. Chuanhang Display and other specialized manufacturers offer industrial-grade modules that operate from -20°C to +70°C and beyond.

From the straightforward LCD 16x4 character module to the versatile 128x64 graphic LCD display, these components continue to be vital in the embedded world. Whether you need a standard off-the-shelf component or a fully customized solution, the choice of manufacturer is paramount.

A strong LCD module factory ensures quality and reliability, while a skilled custom LCD display manufacturer like Chuanhang Display provides the flexibility to bring innovative product designs to life. By understanding the capabilities, applications, and common pitfalls of these displays, engineers and product designers can make informed decisions, ensuring their devices communicate effectively and reliably with the end-user.