In today's technologically driven world, we interact with displays constantly. From the intricate dashboard of a car to the detailed readout of a medical device, these interfaces are crucial. At the heart of many such applications lies the Graphic LCD Display Module. This versatile component is more than just a simple screen; it's the window through which complex data and visuals are communicated. This article delves into the world of graphic LCD display modules, exploring their inner workings, diverse applications, and the common challenges engineers face when integrating them.

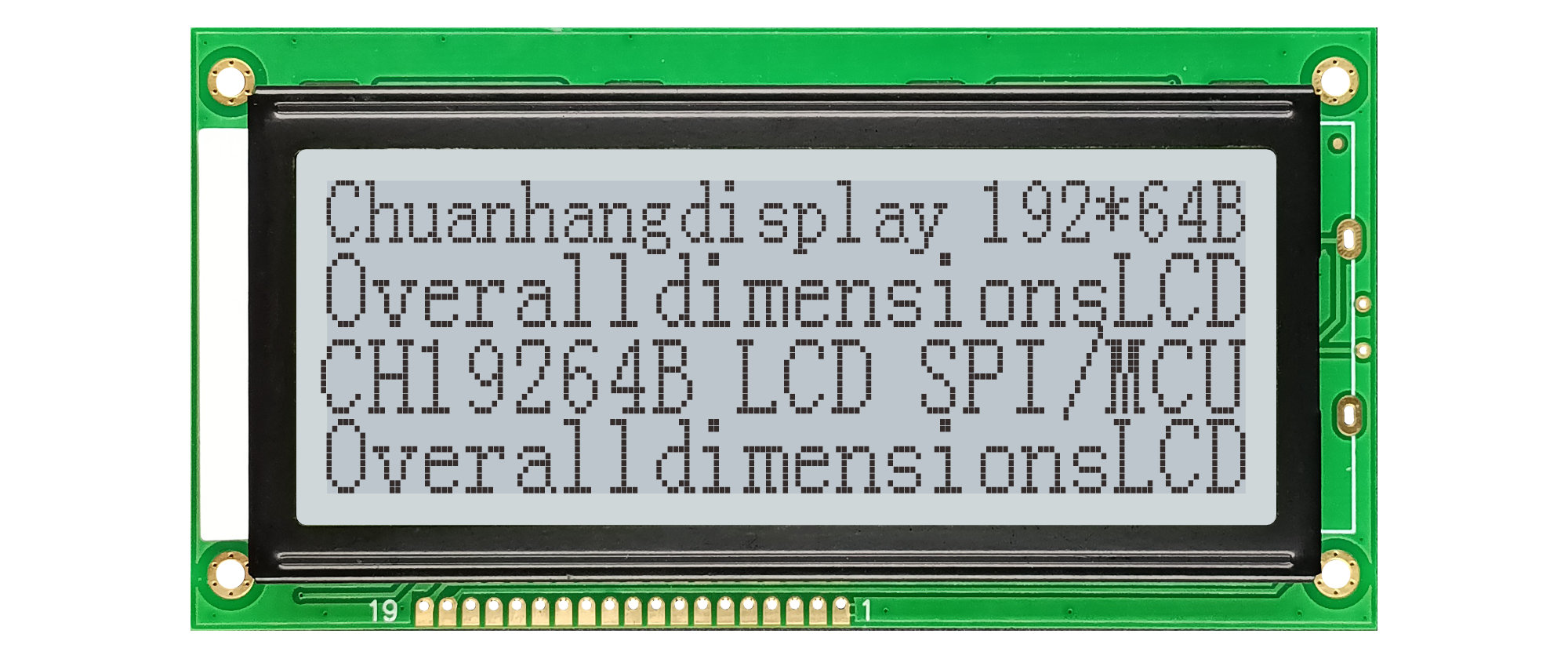

Whether you're a product designer, an engineer, or simply a tech enthusiast, understanding this technology is key to appreciating the devices we use every day. We will also highlight how manufacturers like Chuanhang Display are contributing to this field with robust and reliable solutions.

A Graphic LCD Display Module is a self-contained unit that combines a liquid crystal display (LCD) capable of rendering arbitrary images with all the necessary electronics to control it. Unlike character LCDs, which can only display a fixed set of alphanumeric characters and symbols, a graphic LCD is a pixel-addressable grid. This means you can control each individual pixel (dot) on the screen, enabling the display of custom shapes, logos, graphs, and even complex user interfaces.

The module typically consists of:

The LCD Panel: The physical screen containing the liquid crystal matrix sandwiched between two polarizing filters.

The Controller IC: The "brain" of the module (e.g., Solomon Systech SSD1306, Sitronix ST7920). It interfaces with the host microcontroller (MCU) and handles the low-level task of updating the pixels on the screen based on received commands and data.

The Backlight: Often an array of LEDs placed at the edges or behind the panel to illuminate the display for visibility in low-light conditions.

A Printed Circuit Board (PCB): That hosts the controller, connectors, and other passive components.

This integrated approach simplifies design for engineers, as the complex task of driving the LCD is handled by the module's internal controller.

The operation of a graphic LCD display module is a fascinating interplay of physics and electronics. The core principle relies on the manipulation of light by liquid crystals. These crystals do not emit their own light but instead act as shutters, twisting to either block or allow light from the backlight to pass through.

The internal controller chip maintains a memory buffer known as the GDDRAM (Graphic Display Data RAM). This RAM map directly corresponds to the pixels on the screen. Each bit in this memory represents the state (on or off) of a single pixel. When the host MCU wants to update the display, it sends commands and data to the controller via a standard communication protocol like SPI (Serial Peripheral Interface) or I2C (Inter-Integrated Circuit). The controller interprets these commands—such as setting the cursor position—and writes the pixel data to the appropriate location in the GDDRAM.

The controller then continuously scans the contents of the GDDRAM, applying the correct voltages to the electrodes on the LCD panel to align the liquid crystals and thus create the visible image. This separation of concerns allows a relatively simple MCU to control a complex display efficiently.

Graphic LCD display modules come in various sizes, resolutions, and technologies to suit different applications. The most common types include:

Monochrome STN (Super Twisted Nematic): These are widespread and cost-effective. They offer a passive matrix design, suitable for applications requiring simple graphics and text. They are commonly found in industrial control systems, handheld instruments, and older mobile devices.

TFT (Thin-Film Transistor) LCDs: This is an active matrix technology where each pixel is controlled by its own transistor. This allows for faster refresh rates, higher contrast, and better viewing angles than STN. TFT modules are used wherever high-quality images are needed, such as in consumer electronics, advanced medical equipment, and GPS units.

FSTN (Film Compensated STN): An enhancement of STN that adds a film layer to provide better contrast and a more neutral background color (often a sharper gray-on-gray or gray-on-blue) compared to the yellowish-green of standard STN.

A manufacturer like Chuanhang Display typically offers a wide portfolio of these types, providing engineers with options ranging from small 128x64 pixel displays to larger VGA-resolution modules.

The pixel-level control offered by a graphic LCD display module makes it indispensable across countless industries. Their ability to present custom data visually is their greatest strength.

Industrial Automation: Used in Human-Machine Interfaces (HMIs) for factory equipment, PLCs, and control panels to display system status, diagnostics, and real-time process data.

Medical Devices: Critical for patient monitoring systems, diagnostic equipment, and portable medical devices where clear, reliable presentation of waveforms (like ECG), readings, and alerts is non-negotiable.

Automotive: Found in dashboards, infotainment systems, and control panels for climate control, providing the driver with essential information.

Consumer Electronics: Powers the display on smart home thermostats, audio amplifiers, fitness trackers, and various other gadgets.

Test and Measurement Equipment: Used in oscilloscopes, multimeters, and signal generators to visualize waveforms and detailed measurement results.

Why is the graphic LCD display module such a popular choice? The benefits are clear:

Flexibility: The ability to display any arbitrary image, graph, or user interface element is its primary advantage over segmented or character-only displays.

Integrated Solution: The inclusion of a controller, and sometimes a negative voltage generator for the LCD bias, significantly reduces the design complexity and component count for the end-product developer.

Low Power Consumption: Especially in reflective or transmissive models without a constant backlight, LCD technology is very power-efficient, making it ideal for battery-operated devices.

Cost-Effectiveness: For monochrome displays, particularly in high volumes, the technology offers a very competitive price-to-performance ratio.

Readability: Under good lighting conditions, LCDs offer excellent readability without the eye strain associated with emissive displays like OLEDs.

Despite their advantages, integrating a graphic LCD display module can present some challenges. Being aware of these common issues can save significant development time and frustration.

1. Display Contrast and Readability Issues

A frequent problem is poor contrast, making the display too faint or washed out. This can be caused by an incorrectly adjusted bias voltage (Vo/VLCD), an improperly set viewing angle, or insufficient backlighting. The solution often involves fine-tuning the controller's contrast register and ensuring the backlight is driven at its specified voltage and current.

2. "Ghosting" or Image Retention

Ghosting occurs when a faint remnant of a previous image remains visible. This is often a sign of DC voltage components damaging the liquid crystals over time. Ensuring the driving scheme is truly AC-coupled is crucial. This is typically handled correctly by the controller IC, but faulty circuit design can sometimes introduce issues.

3. Dead Pixels or Lines

A dead pixel (always on or always off) or an entire dead row/column is usually a result of a manufacturing defect in the LCD glass itself. It is often not repairable in the field, underscoring the importance of sourcing modules from reputable suppliers like **Chuanhang Display** that have strict quality control.

4. Communication Failures (SPI/I2C)

If the MCU cannot communicate with the display controller, the screen will remain blank. This is commonly due to incorrect wiring, mismatched voltage levels between the MCU and the module (e.g., 5V vs. 3.3V), misconfigured communication settings (clock polarity, phase, speed), or incorrect initialization routines in the software.

5. Temperature Sensitivity

Liquid crystals have a specified operating temperature range. In very cold conditions, the response time can slow down significantly, causing noticeable lag. In very hot conditions, the LCD may turn black. It is vital to select a module rated for the environmental conditions of the final application.

The graphic LCD display module remains a cornerstone of human-machine interaction. Its perfect blend of flexibility, reliability, and cost-effectiveness ensures its continued relevance in a world increasingly dominated by high-resolution touchscreens. For developers, understanding its operation, benefits, and potential pitfalls is key to a successful implementation.

While new technologies like OLED and E-paper continue to evolve, the LCD module, championed by manufacturers committed to quality and innovation like Chuanhang Display, will continue to illuminate our interfaces for years to come, providing a clear view into the digital world. By carefully selecting the right module and thoughtfully addressing common integration challenges, engineers can leverage this proven technology to create intuitive and effective products.