When you think about the screens that power our daily lives—from smartphones and laptops to medical devices and industrial equipment—you’re thinking about products that began their journey in an LCD display factory. These facilities are the heartbeat of modern visual technology, blending precision engineering with large-scale manufacturing. But what really goes on behind those cleanroom doors? In this article, we take you inside the world of LCD manufacturing, explore common challenges, and highlight how a trusted manufacturer like Chuanhang Display excels in this competitive field.

An LCD display factory is where raw materials are transformed into the functional screens we rely on every day. These factories operate within tightly controlled environments to produce liquid crystal displays (LCDs) of various sizes, resolutions, and specifications. The process involves multiple stages, including designing, etching, printing, assembling, and testing.

Global demand for LCDs continues to grow, not only in consumer electronics but also in sectors such as healthcare, automotive, and smart appliances. This means that a modern LCD display factory must be adaptable, innovative, and quality-driven. Companies like Chuanhang Display invest heavily in R&D and automated production lines to meet diverse market needs while maintaining high standards.

Understanding the manufacturing process helps appreciate the complexity behind each display unit. Here’s a simplified breakdown:

Design and Fabrication: It all starts with product design based on client requirements or market trends. Photomasks are created to form the electrical circuits that control the liquid crystals.

Array Process: Thin-film transistors (TFTs) are deposited on glass substrates through photolithography. This forms the foundation of the LCD.

Cell Assembly: The glass is combined with liquid crystal material and polarizing filters. This is one of the most sensitive stages, requiring a dust-free environment.

Module Assembly: Drivers, PCBs, backlights, and other components are integrated into the unit.

Testing and Quality Control: Each module undergoes rigorous testing for functionality, durability, brightness, color accuracy, and more.

Throughout these stages, an advanced LCD display factory utilizes automation to minimize errors and maximize output.

Even with cutting-edge technology, LCD production isn’t without its hurdles. Here are some frequent issues faced by manufacturers and how they are addressed:

1. Dead or Stuck Pixels

This is one of the most common defects end-users notice. It occurs when a pixel fails to change color. Factories implement advanced array testing and repair protocols to reduce such issues.

2. Backlight Bleeding

Uneven lighting or light leakage from the edges can impair visual quality. This is often due to improper assembly or low-quality materials. Reputable suppliers like Chuanhang Display use high-grade LEDs and precise mounting techniques to prevent this.

3. Low Yield Rates

The complexity of LCD manufacturing means that not every unit produced will pass quality checks. optimizing production flow and continuous process monitoring are essential to improve yield.

4. Environmental Sensitivity

LCDs are vulnerable to extreme temperatures, humidity, and physical shock. Factories must simulate real-world conditions during testing to ensure reliability.

5. Compatibility and Integration Issues

Displays must work seamlessly with other electronic components. This requires close collaboration with clients during the design phase—a specialty of Chuanhang Display, which offers custom-tailored solutions.

A robust QC system is what separates leading manufacturers from the rest. In a typical LCD display factory, quality assurance includes:

Automated Optical Inspection (AOI) for detecting defects.

Aging tests where displays are run for extended periods under high stress.

Environmental tests involving temperature, humidity, and vibration.

Electrical testing to ensure compliance with power and signal requirements.

Chuanhang Display employs a multi-layered QC approach, ensuring that every display shipped meets international standards and customer expectations.

Not all displays are created equal. Different applications require different features. For instance, a display for outdoor use needs high brightness and wide temperature tolerance, while one for a medical device must offer color accuracy and reliability.

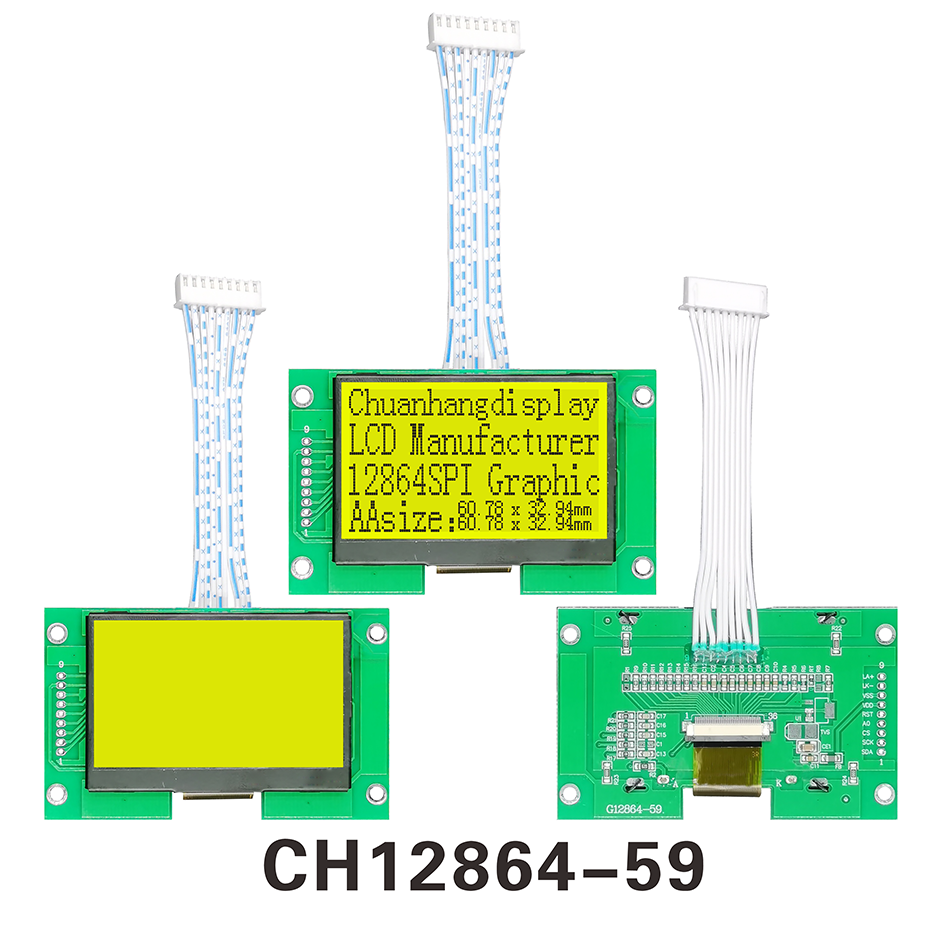

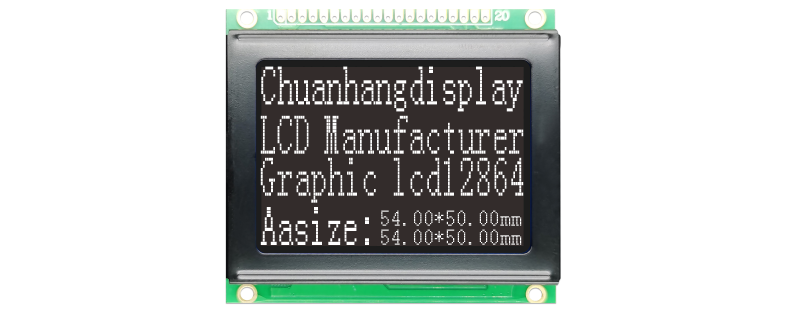

This is where customization becomes critical. A forward-thinking LCD display factory like Chuanhang Display offers:

Tailored sizes and resolutions

Custom touch interfaces (resistive, capacitive)

Specialized coatings (anti-glare, anti-fingerprint)

Enhanced durability for industrial or automotive use

Support for unique connector types or communication protocols

By working closely with clients from concept to mass production, factories can deliver displays that perfectly match the application.

As electronic waste becomes a growing concern, environmentally responsible manufacturing is gaining importance. Modern LCD factories are adopting green practices such as:

Reducing energy and water consumption during production

Using recyclable or biodegradable packaging

Complying with RoHS and REACH regulations

Implementing waste management systems

Chuanhang Display is committed to sustainable manufacturing without compromising on performance or reliability.

Selecting a manufacturing partner is one of the most critical decisions for brands and OEMs. The right LCD display factory should offer:

Proven experience and technical expertise

The ability to scale production up or down

Strong communication and project management

Compliance with industry certifications

After-sales support and warranty services

Chuanhang Display has built a reputation based on quality, reliability, and customer service—making it a preferred partner for businesses worldwide.

The world inside an LCD display factory is both intricate and fascinating. From addressing common issues like dead pixels and backlight bleeding to offering customization and sustainable solutions, these factories play a crucial role in bringing technology to life. Whether you’re a product designer, engineer, or procurement specialist, understanding how these facilities operate—and partnering with experienced manufacturers like Chuanhang Display—can make all the difference in your next project.

Interested in learning more or starting a custom display project? Reach out to a specialized LCD display factory that values innovation and quality as much as you do.