If you’ve ever used a digital watch, a calculator, or a medical device, chances are you’ve interacted with a COG LCD Module. This technology is fundamental to countless electronic devices, yet it often goes unnoticed. But what exactly is a COG LCD Module, and why is it so prevalent? This article delves into the inner workings, advantages, and common challenges associated with these ubiquitous displays, highlighting why brands like Chuanhang Display specialize in their production.

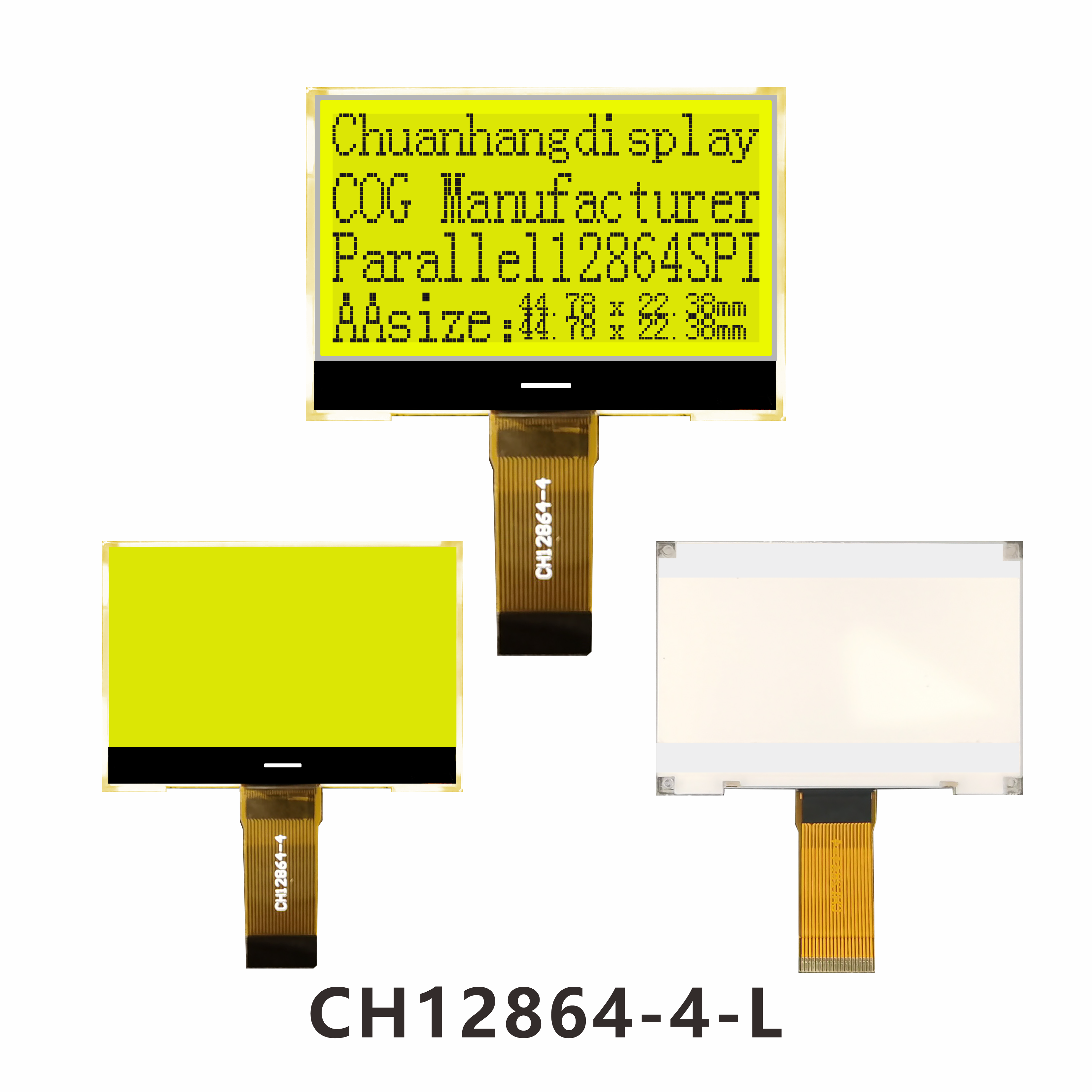

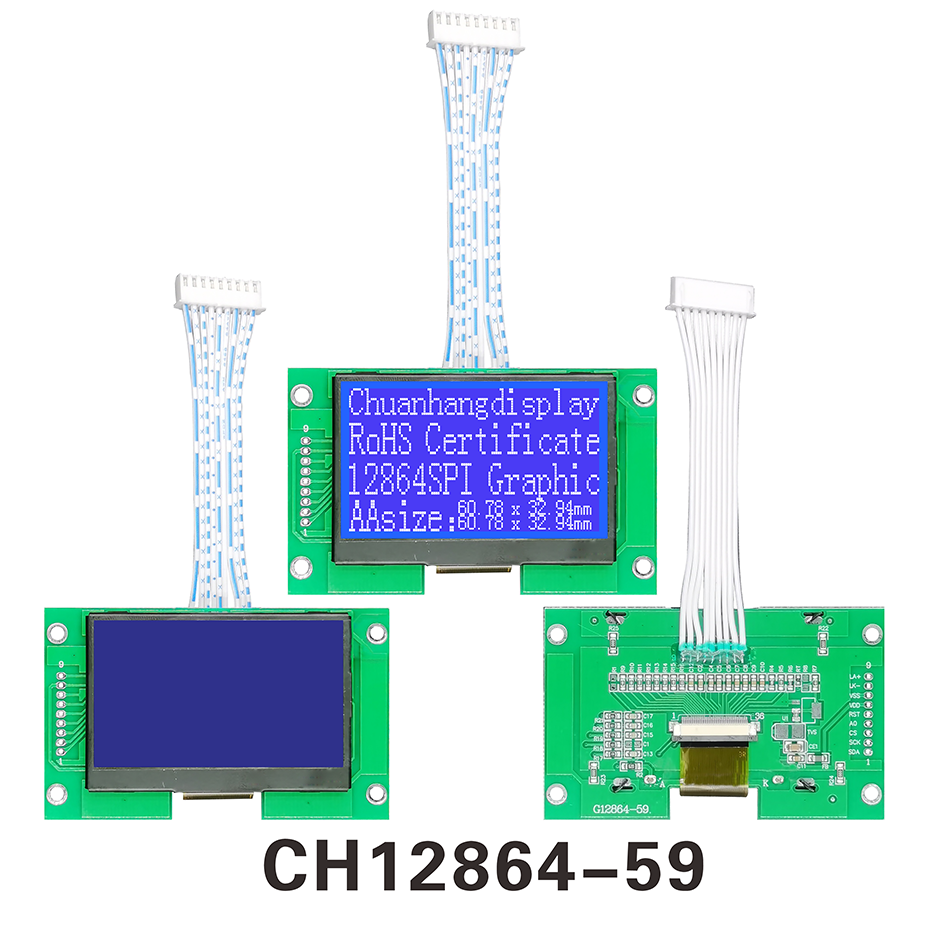

Essentially, a COG LCD Module (Chip-On-Glass Liquid Crystal Display Module) represents a significant advancement in display manufacturing. It integrates the driver Integrated Circuits (ICs) directly onto the glass substrate of the LCD itself. This integration is a departure from older technologies like PCB (Printed Circuit Board) mounted drivers, leading to a more compact, reliable, and cost-effective solution for a wide array of applications.

To truly appreciate a COG LCD Module, it's crucial to understand how it’s constructed. A standard LCD requires a driver circuit to control the individual pixels that form images or characters. In traditional designs, this driver IC is mounted on a separate PCB, which is then connected to the glass display using a flexible printed circuit (FPC) or zebra strips (elastomeric connectors).

The COG LCD Module eliminates this separate mounting. Instead, the driver IC is bonded directly onto the glass substrate using a precise adhesive and then connected via ultra-fine wiring. This process is performed under highly controlled conditions. The result is a single, unified unit where the display and its brain (the driver) are fused together. This direct attachment reduces the number of components and connection points, which is the source of most of its benefits. This miniaturization is why you find COG LCD modules in devices where space is at a premium.

Why has the COG LCD Module become such a popular choice? The advantages are multi-faceted and impact both the manufacturer and the end-user.

Compact Size and Slim Profile: By removing the need for a separate driver PCB and simplifying internal connections, COG LCD modules are significantly thinner and more compact. This is invaluable for modern consumer electronics like smart home devices, wearables, and portable instruments that demand sleek, space-saving designs.

Enhanced Reliability and Durability: Fewer physical connections mean fewer potential points of failure. The direct chip-on-glass construction is less susceptible to problems caused by vibration, shock, or loose connectors. This makes COG LCD modules exceptionally reliable for automotive dashboards, industrial control panels, and outdoor equipment that face harsh environments.

Superior Image Quality and Reduced Electrical Noise: The shorter electrical paths between the driver IC and the glass electrodes minimize signal delay and cross-talk. This results in sharper contrast, better visibility, and lower electromagnetic interference (EMI), which is critical for medical and communication devices.

Cost-Effectiveness in High-Volume Production: While the initial setup for COG technology can be complex, it becomes highly economical for large production runs. The simplified assembly process, with fewer parts to purchase and assemble, lowers the overall Bill of Materials (BOM) and manufacturing costs. Companies like Chuanhang Display leverage this efficiency to provide high-quality, affordable displays to their clients.

The unique blend of size, reliability, and cost makes the COG LCD Module the go-to solution for a diverse range of industries. You will encounter them in:

Consumer Electronics: Kitchen appliances, remote controls, smart thermostats, and toys.

Industrial and Automotive: Measurement tools, control readouts, dashboard displays, and timer panels.

Medical Devices: Portable monitors, blood glucose meters, infusion pumps, and diagnostic equipment where reliability is non-negotiable.

Home Automation and IoT: Thermostats, security system keypads, and sensor displays that require always-on, low-power screens.

Personal Gadgets: Basic mobile phones, pagers, and calculators.

Brands like Chuanhang Display often work with clients across these sectors to provide custom COG LCD module solutions tailored to specific size, interface, and performance requirements.

Despite their many benefits, COG LCD modules are not without their potential issues. Being aware of these common problems can help in selecting a reliable supplier and designing a robust product.

1. Glass Substrate Fragility

The most significant inherent weakness is the fragility of the glass substrate. While the integrated design is robust against vibration, the glass itself can be cracked or shattered by physical impact or excessive pressure during assembly. This necessitates careful handling throughout the manufacturing and installation process.

2. Irreparable Damage

Unlike displays with separate driver boards, a **COG LCD Module** is a single integrated unit. If the driver IC bonded to the glass fails, or if the glass breaks, the entire module must be replaced. There is no option for repairing just one component, which can be a consideration for long-lifecycle products.

3. Heat Sensitivity During Soldering

The materials used in the **COG LCD Module**, particularly the adhesives and the liquid crystal itself, are sensitive to high temperatures. If the module is exposed to excessive heat during the soldering of its connecting pins to a main PCB, it can cause permanent damage. This often manifests as: * **Black Spots:** Permanent discoloration on the screen. * **Ghosting:** faint images that persist on the display. * **Complete failure** of the LCD to function.

Using careful temperature-controlled soldering processes is essential to avoid this.

4. Electrostatic Discharge (ESD) Sensitivity

The driver IC and the fine traces on the glass are highly susceptible to damage from electrostatic discharge. Without proper ESD protection protocols during handling and assembly, an unnoticed static shock can easily destroy the module, leading to dead pixels, lines on the display, or total failure.

5. Limited Customization Flexibility

While companies like **Chuanhang Display** offer a degree of customization, the integrated nature of COG means that changing the display size or resolution often requires a completely new glass mask set and driver IC configuration. This can make prototyping and small-batch custom orders more expensive and time-consuming compared to more modular display types.

Mitigating the common issues associated with COG LCD modules often comes down to partnering with an experienced and reputable manufacturer. This is where a brand like Chuanhang Display proves its value. A reliable supplier will:

Use high-quality glass and bonding materials to enhance durability.

Implement strict quality control checks for ESD protection and heat damage.

Provide clear technical documentation on handling and soldering requirements.

Offer robust packaging designed to protect the fragile modules during shipping.

Work with engineers to design the display into the product correctly from the outset.

The COG LCD Module is a testament to how engineering innovation can lead to smaller, more reliable, and more efficient electronic components. Its technology, which integrates the driver directly onto the glass, has enabled the sleek and dependable devices we rely on daily. While challenges like fragility and heat sensitivity exist, they are manageable with proper design and handling practices. By understanding both the strengths and common pitfalls of COG LCD modules, designers and manufacturers can effectively leverage this technology. Partnering with an established supplier like Chuanhang Display ensures access to high-quality modules and the technical expertise needed to navigate any potential issues, ultimately leading to a superior end product.