Sourcing components for electronic devices is a complex task, but few components are as critical as the display. It is the face of your product and the primary interface for your user. Whether you are developing a new medical device, an automotive dashboard, or a smart home controller, the quality of your display module defines the user experience.

Choosing the right partner is about more than just comparing price sheets. It requires a deep look into manufacturing capabilities, quality control, and long-term stability. Finding a dependable lcd screen supplier can be the difference between a successful product launch and a supply chain nightmare. This article breaks down the practical steps to identifying a partner that fits your engineering and commercial needs, with insights from industry standards and Chuanhang Display.

The lifecycle of consumer electronics is short, but industrial and commercial products often need to remain in production for five to ten years. A major risk in the display market is the "End of Life" (EOL) notice. If your supplier abruptly stops producing a specific panel, you face expensive redesigns and re-certifications.

A strategic partner understands the importance of continuity. They will manage the supply chain of glass substrates, driver ICs, and backlights to ensure your specific configuration remains available. When vetting a potential partner, ask about their EOL notification policy. A competent lcd screen supplier should offer a replacement roadmap that is pin-to-pin compatible, minimizing the impact on your PCB design.

When you engage with a manufacturer, their engineering team should speak your language. If they cannot offer consultation on technical trade-offs, they are likely just a reseller, not a true manufacturer.

The market is dominated by TN (Twisted Nematic) and IPS (In-Plane Switching) panels. While TN panels are cost-effective and fast, they suffer from poor viewing angles and color inversion. For modern applications, most buyers prefer IPS technology. You need to verify if the supplier can source "All Viewing Angle" glass (often denoted as 85/85/85/85 degrees).

Indoor devices usually require 200 to 350 nits of brightness. However, if your device is used outdoors, you need a high-brightness solution, typically ranging from 800 to 2500 nits. High brightness generates heat, so your lcd screen supplier must understand thermal management and efficient LED backlight design to prevent the screen from overheating or dimming prematurely.

Connecting the display to your motherboard is a common stumbling block. The supplier must offer the correct interface options:

MCU / SPI: Common for small, low-resolution screens.RGB: Standard for mid-size screens without internal controllers.LVDS: Essential for larger industrial screens (7 inches and up) due to better noise immunity.MIPI: The standard for high-resolution, high-speed mobile and tablet displays.

In the electronics hub of Asia, distinguishing between a factory and a trading company is difficult. Both have their place, but for custom projects, working directly with a manufacturer like Chuanhang Display offers distinct advantages.

Trading companies often aggregate products from various sources. This might provide a wide catalog, but it introduces inconsistency. You might receive Batch A from one factory and Batch B from another, leading to subtle color differences or firmware mismatches.

A direct factory controls the Bill of Materials (BOM). They can lock in the specific polarizer, backlight structure, and IC controller. This consistency is vital for brand integrity. Furthermore, communication is faster. When you have a technical question about timing sequences or initialization code, a direct supplier connects you with the engineer, not a sales middleman who has to relay messages.

Off-the-shelf products rarely fit perfectly into a new housing design. The ability to customize is a hallmark of a mature supplier.

The Flexible Printed Circuit (FPC) connects the screen to your board. Often, the stock FPC is too short, too long, or has the wrong pinout. A capable supplier can redesign the FPC shape and pin definition for a relatively low Non-Recurring Engineering (NRE) fee.

Modern displays almost always require touch functionality. Your supplier should offer both Resistive (RTP) and Capacitive (CTP) touch panels. More importantly, they should handle the bonding process.

Tape Bonding (Air Bonding): A cost-effective method where the touch panel is attached to the LCD bezel. Ideally used indoors.Optical Bonding: A premium process where resin or OCA fills the gap between the LCD and the cover glass. This eliminates reflections and prevents condensation, which is critical for outdoor equipment.

The cover glass is the only part of the device the user touches. Brands like Chuanhang Display allow you to customize this glass with your logo, specific cutouts for cameras, and surface treatments like Anti-Glare (AG), Anti-Reflective (AR), or Anti-Fingerprint (AF) coatings.

Price negotiation is inevitable, but understanding what drives cost helps you negotiate better. The most expensive component in a module is usually the LCD glass cell (open cell), followed by the driver IC and the backlight unit.

Global shortages can affect driver IC prices. A transparent lcd screen supplier will explain market trends rather than arbitrarily raising prices.

Minimum Order Quantity (MOQ) is another friction point. Large Tier-1 manufacturers often ignore orders under 100k units. However, flexible suppliers specifically catering to the industrial sector often accept MOQs as low as 500 or 1,000 units per batch. Some, recognizing the potential of a startup, may even support smaller pilot runs.

Trust is good, but verification is better. Before signing a contract, you must understand the supplier's Quality Assurance (QA) process.

1. Incoming Quality Control (IQC):Does the factory inspect the raw glass and ICs before assembly?

2. In-Process Quality Control (IPQC):Are there automated checks during the bonding and assembly stages?

3. Reliability Testing:This is the most critical step. Ask for their reliability reports. Standard tests should include:

High/Low-Temperature Storage and Operation (e.g., -20°C to +70°C).High Humidity operation (typically 60°C at 90% humidity).Vibration and Drop testing.

4. Cosmetic Standards:The industry uses strict standards for dead pixels and foreign particles. Ask your supplier if they adhere to Class A standards (zero bright dots) or Class B standards. Be clear about what is acceptable for your specific product tier.

Many procurement teams make the mistake of selecting the lowest bidder without validating the "BOM List." A low price often means the supplier is using recycled glass cells or B-grade panels. These screens might look fine initially but will develop lines, flickering, or yellowing after a few months of use.

Another pitfall is ignoring the backlight lifetime. A standard industrial LED backlight should last 30,000 to 50,000 hours (to half brightness). Cheaper suppliers may use lower-quality LEDs that degrade within 10,000 hours. Always specify the half-life requirement in your datasheet.

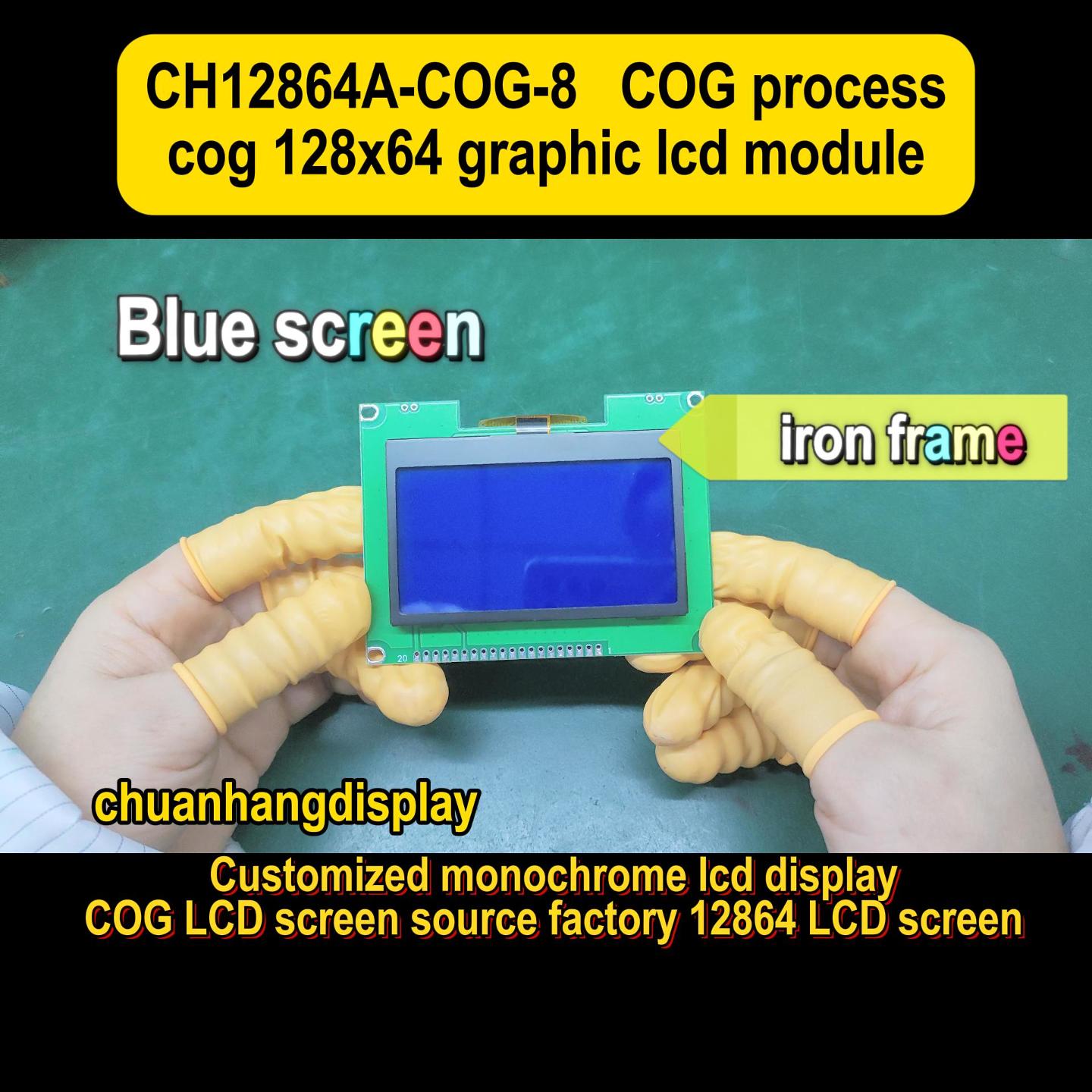

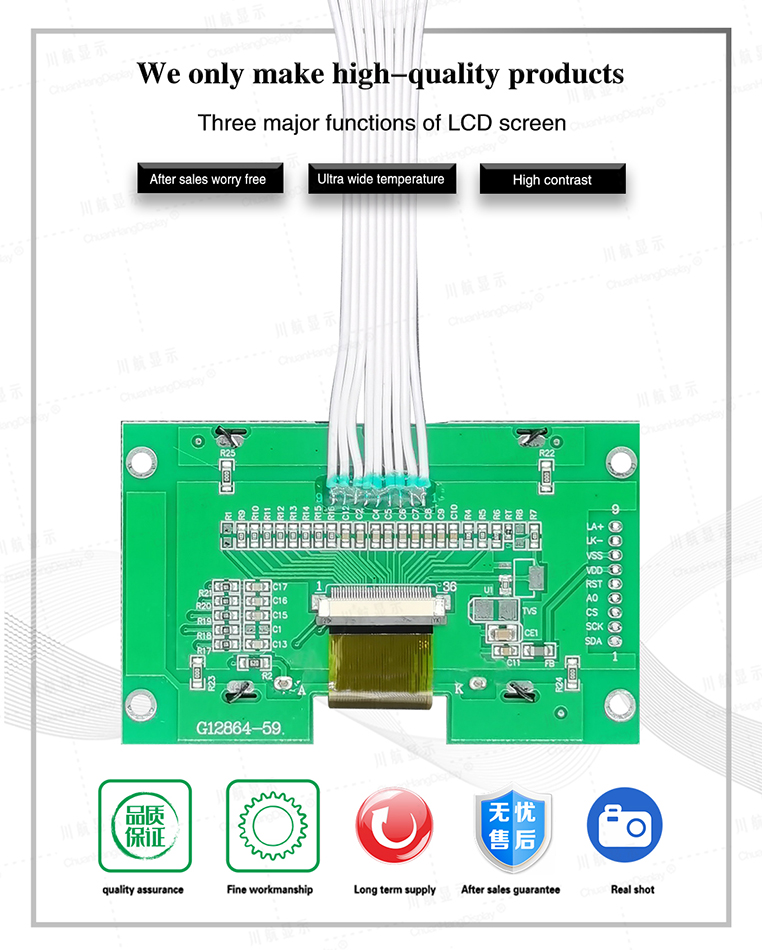

When looking for a balance between engineering depth and commercial flexibility, Chuanhang Display stands out as a robust option. Focused on small to medium-sized LCD modules, Chuanhang Display supports clients from the concept phase through to mass production.

Unlike rigid manufacturers that demand massive volumes, Chuanhang Display tailors solutions for diverse industries, including medical instruments, industrial automation, and handheld devices. Their team understands that a datasheet is just a starting point. They provide the initialization code, debugging support, and mechanical integration advice that engineers need to get a product to market quickly.

By controlling their manufacturing lines and maintaining strong relationships with glass and IC foundries, Chuanhang Display ensures supply stability even during volatile market conditions. If you are seeking an lcd screen supplier that acts more like a technical partner than a vendor, Chuanhang is positioned to meet that demand.

The display is the visual anchor of your product. Compromising on it compromises your brand. Finding the right partner involves peeling back the layers of pricing to examine their engineering capability, quality standards, and supply chain robustness.

You need a partner who tells you the truth about lead times and advises you on the best interface for your CPU. Whether you need a high-brightness outdoor screen or a custom-shaped touch panel, the right supplier makes the complex simple.

As you finalize your vendor list, consider the value of direct communication and technical customization. Companies like Chuanhang Display represent the tier of suppliers that bridge the gap between massive generic production and bespoke engineering needs. By following the vetting criteria outlined above—focusing on technology, quality, and long-term support—you will secure a supply chain that supports your business growth for years to come.

Q1: What is the typical lead time for a custom LCD order?

A1: Generally, the lead time for a standard off-the-shelf LCD is 2 to 4 weeks. If you require customization (such as a custom FPC or touch panel), the sample stage typically takes 3 to 5 weeks to account for tooling and engineering. Once the sample is approved, mass production usually requires 4 to 6 weeks depending on material availability.

Q2: Can I get sunlight-readable displays without high power consumption?

A2: Yes, but it requires specific technology. Transflective LCDs are one option, as they reflect sunlight to increase visibility. However, they are expensive and have poorer color saturation. The more common modern solution is using high-efficiency LED backlights combined with optical bonding. Optical bonding reduces reflection significantly, allowing you to run the backlight at a lower brightness (saving power) while maintaining visibility.

Q3: What information do I need to provide to get an accurate quote from an lcd screen supplier?

A3: To get a precise quote, you should provide:

Size and Resolution: (e.g., 5 inch, 800x480).Interface: (e.g., RGB, LVDS, MIPI).Brightness Requirement: (Indoor or Outdoor use).Touch Panel Needs: (None, Capacitive, or Resistive).Estimated Quantity: (MOQ affects price significantly).Application: (Medical, Automotive, Consumer).

Q4: What is the difference between Commercial and Industrial Grade LCDs?

A4: Commercial grade screens are designed for consumer environments (TVs, phones) with operating temperatures usually between 0°C to 50°C and a lifecycle of 1-3 years. Industrial grade screens feature wider operating temperatures (-20°C to +70°C or higher), longer product availability (5-7 years), and higher resistance to shock, vibration, and electromagnetic interference.

Q5: How does Chuanhang Display handle discontinued components?

A5: Supply chain stability is a priority. If a component (like an IC or glass cell) is scheduled to be discontinued by the upstream foundry, Chuanhang Display typically receives notice 6 to 12 months in advance. They will notify the client immediately and offer two options: a "Last Time Buy" to stock up on the old version, or a recommended compatible substitute that requires minimal or no changes to the client's hardware.