Finding a reliable partner for your display needs is often the difference between a successful product launch and a costly technical failure. For many engineers and procurement managers, the search for a custom lcd display manufacturer starts with a technical specification and ends with a long-term partnership built on trust and quality.

Chuanhang Display has spent years navigating the complexities of the display industry. We understand that a screen is more than just a piece of glass; it is the primary interface between your technology and your user. Whether you are building medical equipment, automotive dashboards, or industrial controllers, the display must perform perfectly under specific environmental conditions.

Standard off-the-shelf displays rarely meet the rigorous demands of specialized industries. A standard screen might work in a temperature-controlled office, but it will likely fail in a high-moisture factory or under direct sunlight. This is why choosing a specialized custom lcd display manufacturer is essential for high-stakes applications.

Customization allows you to dictate every aspect of the hardware. You can choose the brightness levels, the viewing angles, the interface type (such as SPI, I2C, or LVDS), and the physical dimensions. Beyond the technical specs, customization ensures that the display fits your housing perfectly, reducing the need for expensive mechanical workarounds.

When you begin your search, you will find hundreds of companies claiming to be experts. However, a true professional partner like Chuanhang Display distinguishes itself through engineering depth and supply chain stability. You should look for a manufacturer that offers end-to-end support, from the initial drawing to the final mass production phase.

Quality certifications are a non-negotiable factor. Ensure your chosen partner adheres to ISO 9001 standards and provides RoHS and REACH compliant materials. In the international market, these certifications act as a baseline for reliability and environmental responsibility.

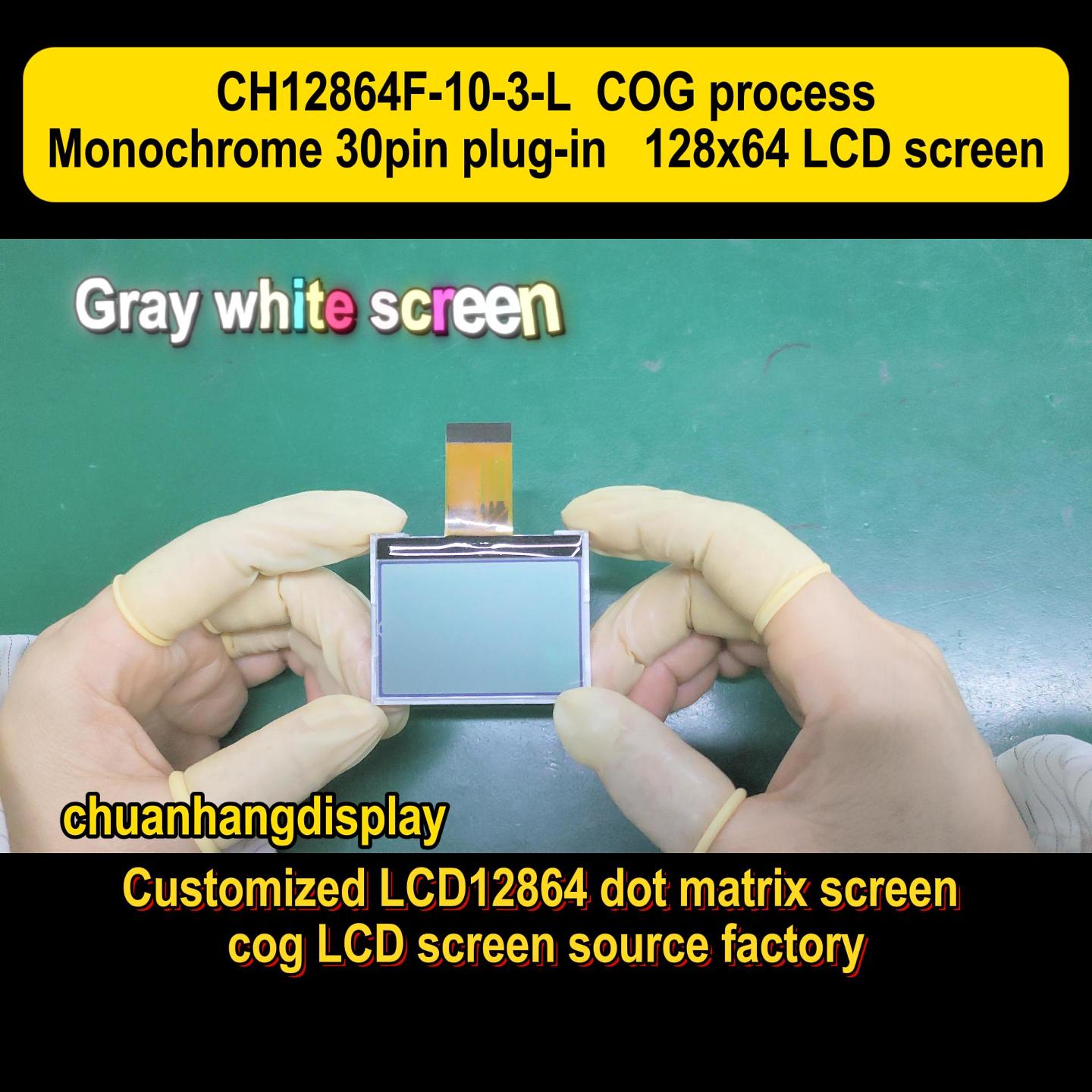

The process of creating a bespoke display usually begins with a feasibility study. Your custom lcd display manufacturer should analyze your requirements to determine which panel technology—be it TN, STN, FSTN, or high-resolution TFT—is most appropriate for your budget and performance needs.

After the technology is selected, the design phase involves creating a detailed CAD drawing of the module. This includes the glass layout, the Flex Printed Circuit (FPC) design, and the backlight configuration. At Chuanhang Display, we emphasize clear communication during this stage to prevent errors that could lead to expensive re-tooling later in the cycle.

One of the most common reasons to seek a custom solution is sunlight readability. Standard displays often wash out when exposed to outdoor light. A professional manufacturer can enhance the backlight using high-efficiency LEDs or add transflective films to the stack-up.

Brightness is measured in nits. While a standard consumer device might sit around 300 nits, industrial outdoor applications often require 1000 nits or more. Your manufacturer should provide options for optical bonding, which reduces internal reflections and significantly improves contrast in bright environments.

Most modern devices require some form of user input. A versatile custom lcd display manufacturer will offer integrated touch solutions, typically either Resistive or Capacitive (PCAP). Capacitive touch is the gold standard for consumer-like feel, supporting multi-touch and gestures.

However, for industrial settings where operators wear thick gloves or where water spray is common, specialized tuning of the touch controller is required. Chuanhang Display works closely with clients to calibrate touch sensitivity, ensuring the screen remains responsive even in harsh environments or through thick cover glass.

Industrial displays face challenges that your phone never encounters. These include extreme temperature fluctuations, mechanical vibrations, and electromagnetic interference (EMI). During the design phase, your manufacturer must consider the operating temperature range.

Wide-temperature liquids allow LCDs to function from -30°C to +80°C. Furthermore, if your device will be used in a medical or food-processing setting, the display must be resistant to chemical cleaners. Choosing a manufacturer that understands these niche requirements is vital for the longevity of your product.

One of the biggest risks in hardware manufacturing is component obsolescence. You do not want to design a display that becomes unavailable six months after you launch your product. A reputable custom lcd display manufacturer like Chuanhang Display provides a long-term supply guarantee.

We focus on using industrial-grade controllers and glass that have a stable production roadmap. If a specific component is reaching its "end of life," your manufacturing partner should provide ample notice and suggest a "pin-to-pin" compatible replacement to minimize the need for a total redesign.

Before moving to mass production, prototyping is a critical milestone. This phase allows you to test the display in the actual application environment. It is the time to check for viewing angle issues, color accuracy, and software compatibility.

A reliable manufacturer will conduct rigorous in-house testing, including thermal cycling, humidity tests, and drop tests. At Chuanhang Display, we believe that testing at the module level prevents failures at the system level. This proactive approach saves our clients significant time and money during the certification of their final products.

The international LCD market is competitive, but Chuanhang Display has carved out a space by focusing on precision and customer service. We understand that every project has unique constraints, whether it is a tight budget or an aggressive timeline.

By acting as a consultant rather than just a vendor, we help our clients navigate the trade-offs between cost and performance. Our engineering team is adept at solving complex integration problems, making us a preferred custom lcd display manufacturer for companies looking to push the boundaries of what their hardware can do.

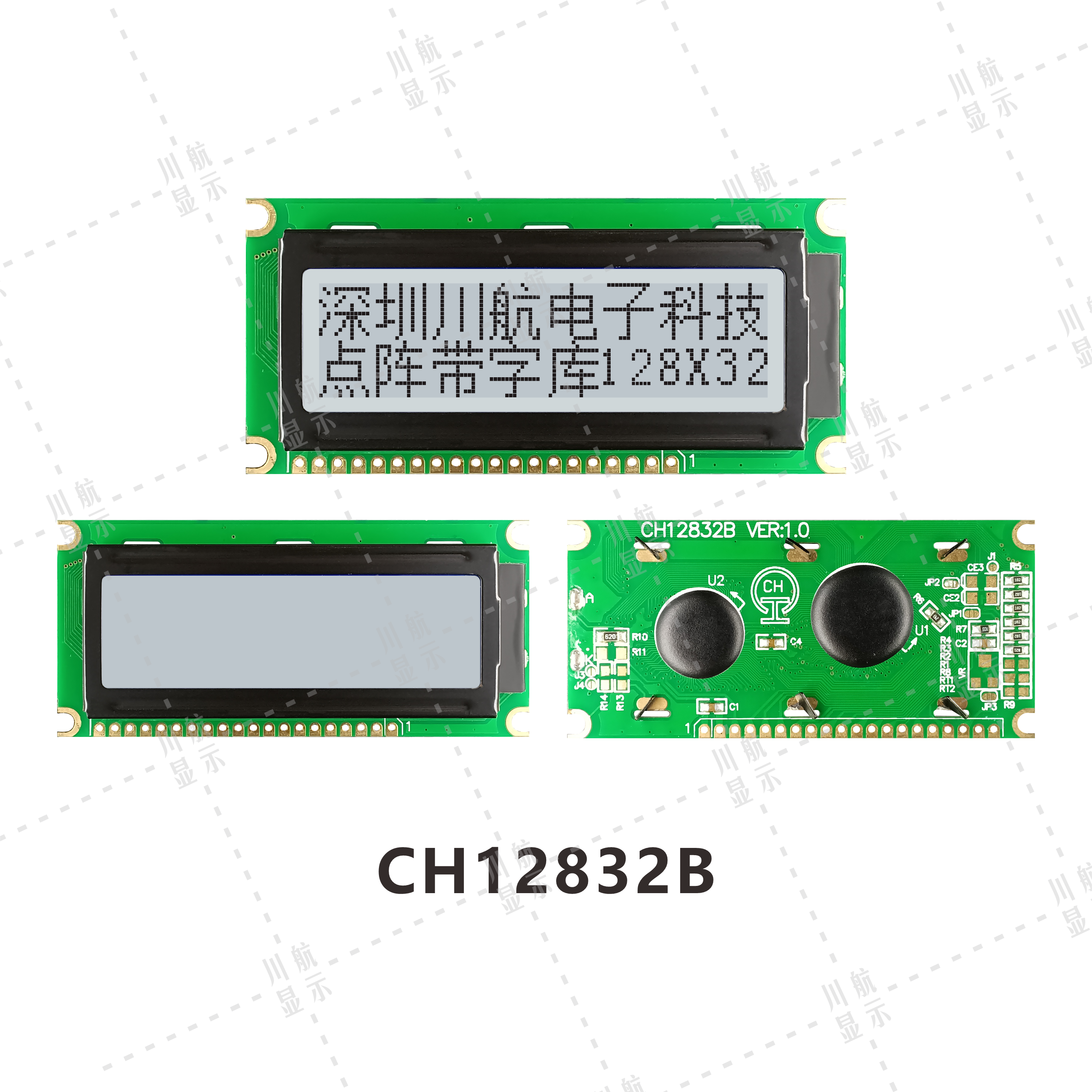

The industry is moving toward higher resolutions and more energy-efficient designs. We are seeing an increased demand for square displays, round displays, and even bar-type stretched displays for retail and signage.

As technologies like Micro-LED and OLED become more accessible for industrial use, a forward-thinking manufacturer must stay ahead of the curve. Chuanhang Display continues to invest in R&D to ensure our clients have access to the latest optical enhancements and power-saving features as they become viable for mass production.

Selecting a custom lcd display manufacturer is a strategic decision that affects your product’s usability, durability, and brand perception. By focusing on technical expertise, quality control, and long-term support, Chuanhang Display provides the foundation for your hardware's success. Whether you need a simple monochrome segment display or a complex high-brightness touch module, the right partnership will turn your vision into a functional reality.

Q1: What is the typical lead time for a custom LCD project?

A1: The timeline usually depends on complexity. Initial drawings and specifications take about 1-2 weeks. Once the design is approved, samples are typically produced within 4 to 6 weeks. Mass production follows after sample approval, usually taking another 6 to 8 weeks depending on the material availability.

Q2: What is the Minimum Order Quantity (MOQ) for a custom display?

A2: MOQs vary based on the technology used. For standard TFT modules with minor customizations (like FPC changes), the MOQ might be as low as 500 or 1000 units. For completely custom glass (like a custom monochrome TN display), the MOQ is often higher to offset the tooling costs, typically starting around 2,000 to 5,000 units.

Q3: Can Chuanhang Display make a screen sunlight-readable?

A3: Yes. We use several techniques to achieve this. The most common methods include increasing the backlight brightness to over 1000 nits, using transflective polarizers, and implementing optical bonding to eliminate the air gap between the touch screen and the LCD panel.

Q4: Do I need to pay a tooling fee for a custom design?

A4: Generally, yes. Tooling fees cover the engineering time and the creation of custom molds or masks for the glass, backlight, and FPC. However, these are usually one-time costs. At Chuanhang Display, we provide a transparent breakdown of these costs during the quoting phase.

Q5: How do you ensure the quality of the displays before they are shipped?

A5: Every module undergoes a series of inspections. This includes automated optical inspection (AOI), manual visual checks for pixel defects, and electrical testing to ensure all functions meet the data sheet specifications. We also perform aging tests on a sample basis from every production lot.

Q6: What interfaces do you support for custom TFT displays?

A6: We support a wide range of interfaces depending on your processor and data requirements. Common options include RGB, MCU (8-bit or 16-bit), SPI, MIPI DSI, and LVDS. Our engineering team can help you determine which interface is best for your specific application's bandwidth and pin-count requirements.