For product engineers and procurement managers, the screen is often the single most critical component in the Bill of Materials (BOM). It is the face of your device. If the screen fails, the product fails. Finding a reliable lcd display supplier is not just about finding the lowest price per unit; it is about securing a partner who understands the intricacies of industrial manufacturing, supply chain stability, and long-term lifecycle management.

Many companies struggle when moving from a prototype phase to mass production. They often find that the generic screens they bought online lack the consistency required for rigorous industrial use. This article outlines what you actually need to look for when vetting a partner, ensuring your supply chain remains robust.

The first step in your sourcing journey is distinguishing between a trading company and a true factory. There is a place for both, but for custom projects, working directly with a manufacturer is usually superior. A factory has direct control over the quality of the glass panel, the backlight assembly, and the driver ICs.

When you work with a direct manufacturer like Chuanhang Display, you gain access to the engineering team. This is crucial when you need to troubleshoot electromagnetic interference (EMI) issues or adjust the timing of the display interface. Traders often lack the technical depth to solve these engineering hurdles quickly.

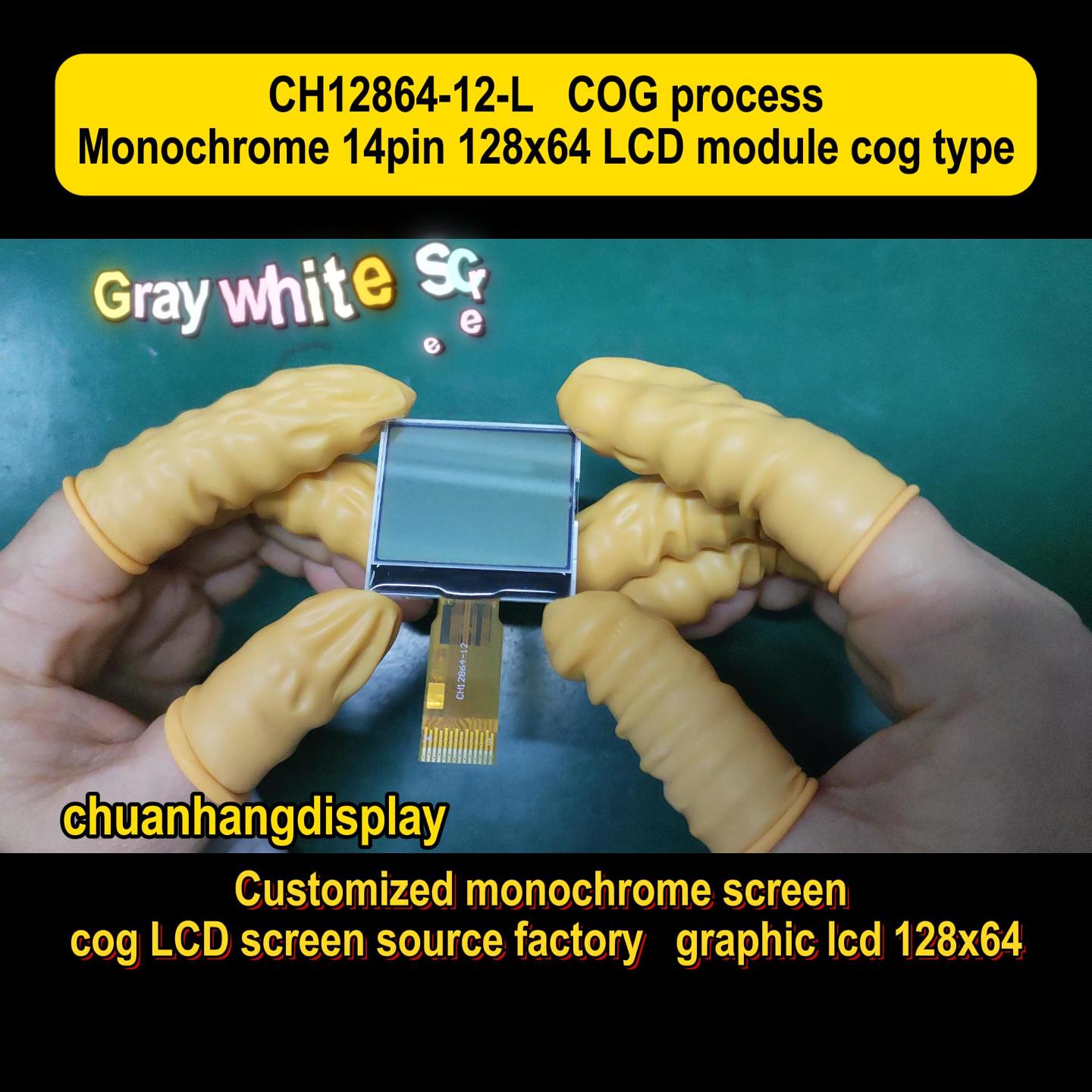

A capable supplier should offer a wide range of technologies. You need to verify if they specialize in the specific type of display your project requires.

TFT vs. MonochromeDoes the vendor offer both? While color TFTs are standard for consumer electronics, many industrial meters still rely on monochrome STN or FSTN displays for their low power consumption and high contrast in sunlight. A versatile supplier will not push you toward a TFT if a monochrome solution is better for your battery life.

Interface OptionsYour microcontroller unit (MCU) dictates the display interface. A competent partner will offer modules that support various interfaces such as SPI, MCU (8080/6800), RGB, LVDS, and MIPI. If a supplier only offers one type of interface, it limits your hardware design flexibility.

Brightness and Viewing AnglesPay attention to the nits. Standard indoor displays usually run between 200 and 300 nits. However, if your device is for outdoor use, you need a high-brightness solution (typically 800 to 1000+ nits). Ask the vendor about their ability to customize the backlight assembly. This is a standard request for Chuanhang Display engineers, who frequently adjust LED arrays to meet specific outdoor readability requirements.

Off-the-shelf products rarely fit perfectly. Perhaps the FPC (Flexible Printed Circuit) cable is too short, or the connector is on the wrong side of the PCB. This is where customization capability becomes the deciding factor.

Non-Recurring Engineering (NRE) costs are fees paid one time to research, design, and test a new product. A reasonable lcd display supplier will be transparent about these costs.

Common Customizations Include:

FPC Shape and Pinout: Redesigning the flex cable to fit your motherboard.Touch Panel Integration: Bonding a Capacitive (PCAP) or Resistive touch screen to the display.Cover Glass: Customizing the glass with your logo, rounded corners, or specific optical coatings (Anti-Glare, Anti-Reflective).

If a potential partner refuses to modify standard modules or quotes exorbitant NRE fees for simple changes, it is a red flag. It suggests they are merely moving boxes rather than manufacturing solutions.

Data sheets can look perfect, but real-world performance is what matters. How does the supplier validate their screens? You need to ask about their testing rigor before signing a contract.

Environmental TestingIndustrial displays must survive harsh conditions. Ask for reports on High-Temperature High-Humidity operational tests (often 60°C at 90% humidity for hundreds of hours).

Aging TestsDoes the factory perform burn-in tests? Running the displays for 24 to 48 hours before shipment helps catch "infant mortality" failures where weak components break early.

Visual Inspection StandardsThe industry standard often references ISO guidelines regarding dead pixels. Be clear about your requirements. Are you accepting "zero dead pixels," or are you following the standard allowing for a few sub-pixel defects? Chuanhang Display adheres to strict visual standards, ensuring that what you receive matches the "Golden Sample" approved during the prototyping phase.

One of the biggest nightmares in electronics is the End-of-Life (EOL) notice. This happens when a core component (like the glass panel or controller IC) is discontinued by the upstream manufacturer.

A strategic lcd display supplier monitors the market trends. They should provide you with a "long-term availability" guarantee, typically 3 to 5 years for industrial products. If a component is going EOL, a responsible partner will:

Notify you months in advance.Secure a "last time buy" of stock for you.Propose a pin-compatible replacement so you do not have to redesign your mainboard.

If your supplier mainly deals in consumer-grade surplus panels, you risk having your supply cut off without warning. Consumer panels change every six months; industrial panels stay consistent for years.

The gap between a sample order and mass production is filled with hundreds of emails. Communication speed and clarity are tangible assets.

Language barriers can cause technical specifications to be misunderstood. Look for a team that responds to technical queries within 24 hours. The sales team should act as a bridge to the engineers, not a barrier.

Furthermore, consider the logistical support. Can they handle Incoterms like DDP (Delivered Duty Paid) if you don't have a logistics department? Do they understand export compliance? Chuanhang Display prides itself on a sales engineering team that understands both the technical specs and the logistics of getting fragile glass components across borders safely.

Modern user interfaces increasingly demand touch interaction. Sourcing the display and the touch panel separately can lead to integration headaches. The air gap between the two can cause parallax errors or allow dust to enter.

Optical Bonding is a service a top-tier supplier should offer. This involves using a resin to glue the touch glass directly to the LCD surface. It improves contrast, ruggedness, and readability.

When vetting a vendor, ask if they do the bonding in-house. Outsourcing this step adds cost and risk. A supplier that handles the entire stack—LCD, touch sensor, and cover lens—takes full responsibility for the warranty of the entire module.

Price is always a factor, but it must be analyzed via Total Cost of Ownership (TCO). A slightly cheaper screen that has a 5% failure rate in the field will cost you far more in returns, repairs, and reputation damage than a premium screen with a 0.1% failure rate.

Minimum Order Quantity (MOQ) is the start of every negotiation. Factories prefer high volume runs. However, a growth-oriented lcd display supplier understands that projects start small. Look for a partner willing to support pilot runs of 100 or 500 units before demanding orders of 5,000+.

Before finalizing your decision, request their documentation.

ISO 9001: This confirms they have a quality management system in place.RoHS / REACH: Essential for selling your products in Europe. You must ensure the displays contain no hazardous materials like lead or mercury.IATF 16949: If you are in the automotive sector, this is mandatory. Even if you aren't, a supplier with this certification operates at a much higher quality standard.

Selecting the right partner is a balance of technical competence, supply security, and communication. You are not just buying a piece of glass; you are buying the assurance that your production line will not stop.

By focusing on customization capabilities, testing rigor, and long-term support, you can filter out the low-quality traders. Companies like Chuanhang Display have positioned themselves to fill this gap, offering the engineering depth of a large manufacturer with the flexibility required for specialized industrial projects.

Take the time to audit your potential lcd display supplier. Ask the hard questions about EOL and testing. Your choice today determines the reliability of your product tomorrow.

Q1: What is the typical Minimum Order Quantity (MOQ) for custom LCD modules?

A1: The MOQ varies based on the technology. For standard off-the-shelf modules, suppliers may allow orders as low as 50 or 100 units. However, for fully custom LCDs requiring unique glass or tooling, the MOQ is typically higher, often ranging from 1,000 to 5,000 units per batch to justify the setup costs.

Q2: How long does the tooling and sample process usually take?

A2: Generally, the design and drawing approval process takes 3 to 5 days. Once the drawing is approved, manufacturing the tooling and producing the initial samples usually takes between 15 to 25 days, depending on the complexity of the touch panel or backlight customization.

Q3: Can I change the interface of an LCD (e.g., from RGB to HDMI)?

A3: You cannot usually change the native interface of the glass panel itself without redesigning the driver IC structure. However, a capable supplier can provide a "controller board" or "bridge board" that converts the signal. For example, they can add a PCB to the back of the module that converts an HDMI signal into the LVDS or RGB signal the panel requires.

Q4: What is the difference between Consumer and Industrial grade LCDs?

A4: Consumer grade displays are designed for short lifecycles (1-2 years), standard indoor temperatures, and lower brightness. Industrial grade displays are built to operate in extreme temperatures (-30°C to +80°C), have long-term availability (5+ years without EOL), and often feature higher brightness and reinforced shock resistance.

Q5: What happens if I receive a display with dead pixels?

A5: This depends on the Acceptable Quality Level (AQL) agreement signed before the order. Most industrial suppliers follow ISO 13406-2 Class II standards, which allow a very small number of defects. However, premium suppliers often offer "Zero Bright Dot" policies for high-end applications, meaning any panel with a stuck white pixel will be replaced under warranty. Always define this in your purchase order.