Sourcing the right LCD screen supplier is a critical decision for any business integrating displays into its products. The supplier you choose directly impacts product quality, cost efficiency, supply chain stability, and ultimately, your market reputation. This decision becomes even more crucial in a complex global market with varying technical standards and quality levels.

This guide provides a clear framework for evaluating and selecting a reliable LCD screen supplier.

First, assess technical capability and product range. A competent LCD screen supplier should offer a diverse portfolio. This includes TFT, IPS, OLED, and industrial-grade displays in various sizes and resolutions. They must also provide detailed datasheets and support for custom solutions.

Second, manufacturing quality and consistency are non-negotiable. Inquire about the supplier's factory certifications, such as ISO 9001 for quality management. A rigorous quality control (QC) process is essential. This includes testing for dead pixels, brightness uniformity, color accuracy, and touch functionality if applicable.

Third, evaluate their supply chain and logistical reliability. A stable LCD screen supplier manages component sourcing effectively to avoid major delays. Understand their lead times for standard and custom orders. Their logistics partners should ensure safe, timely delivery with proper packaging to prevent damage.

Different sectors have vastly different needs. A one-size-fits-all approach from a LCD screen supplier often leads to failure.

For consumer electronics, the focus is on high resolution, slim bezels, vibrant color, and cost-effectiveness. Suppliers must support high-volume orders with flexible scaling.

The industrial and automotive sector demands durability. Screens must operate in extreme temperatures and resist vibration. High brightness for outdoor visibility and extended product lifecycles are key. Suppliers need relevant automotive-grade certifications.

Medical device displays require strict compliance. They need high brightness, exceptional clarity, and often anti-glare coatings. Regulatory standards must be met without compromise. The supplier's documentation and traceability are critical here.

Effective communication separates good suppliers from great ones. A responsive LCD screen supplier provides clear pre-sales and post-sales support.

Pre-sales engineering support helps match the correct display to your application. They should offer sample units for testing and be proactive in suggesting solutions for design challenges.

After-sales service includes handling defects professionally, providing firmware updates if needed, and managing return merchandise authorization (RMA) processes efficiently. Time zone and language compatibility significantly impact project timelines.

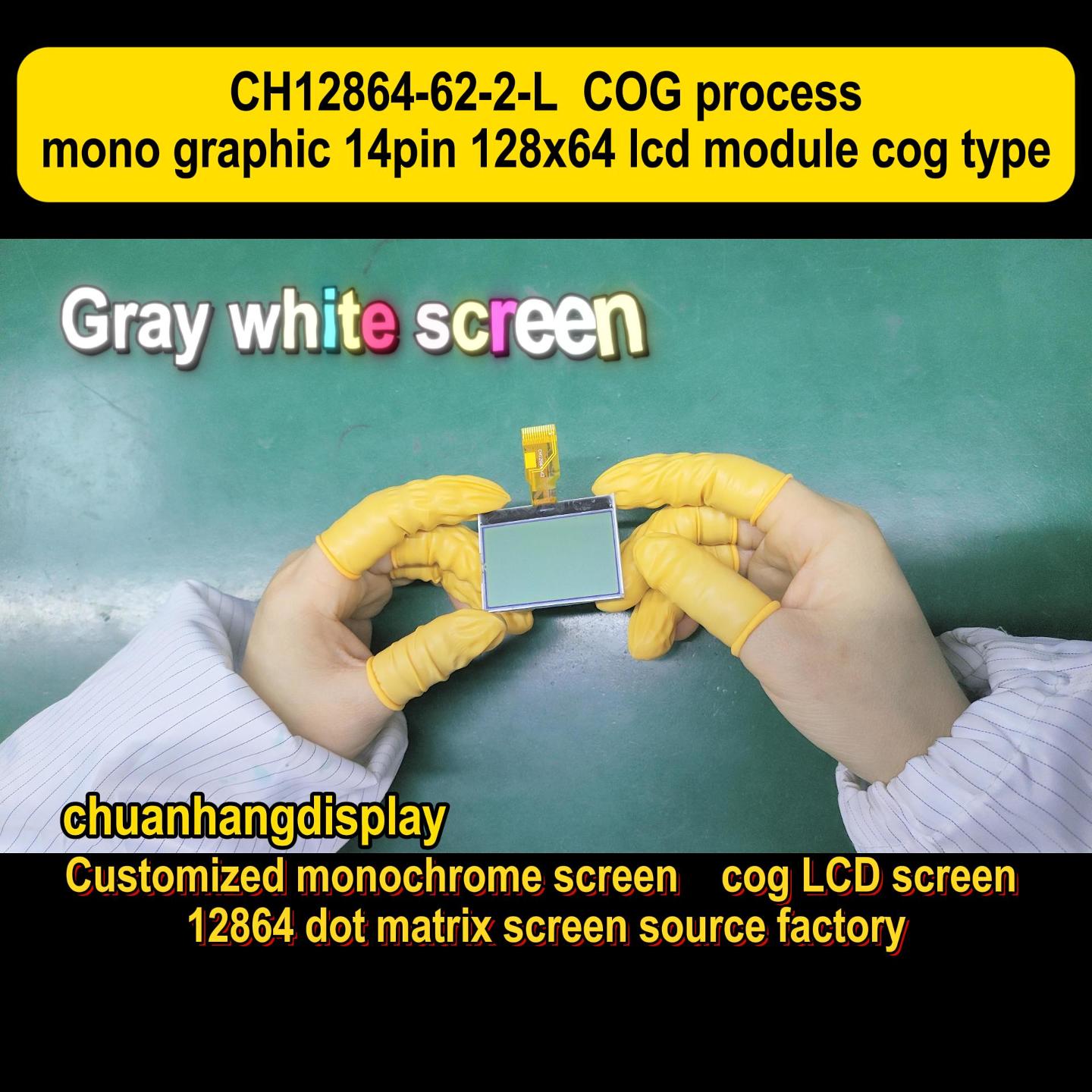

For businesses seeking a balance of quality, service, and technical expertise, Chuanhang Display has established a strong reputation. They focus on providing tailored LCD solutions rather than just off-the-shelf products.

Their strength lies in a streamlined process from prototyping to mass production. Chuanhang Display maintains a modern production facility with strict QC checkpoints at every stage. This ensures every batch meets the agreed specifications.

They specialize in serving sectors like industrial HMI, medical instrumentation, and premium consumer devices. Their engineers work closely with clients to overcome specific design hurdles, such as optical bonding or custom driver board development.

The role of an LCD screen supplier is evolving with technology. Several trends will influence your choice.

First, the shift towards TFT LCD and advanced IPS technology continues for mainstream applications, offering better viewing angles and color. Meanwhile, OLED demand grows for high-end devices where contrast and flexibility are paramount.

Second, integration is key. Suppliers offering value-added services like full turnkey modules (with touch panels and controllers) save significant development time and cost for OEMs.

Finally, sustainability is becoming a contract factor. Suppliers are now evaluated on their environmental policies, use of recyclable materials, and energy-efficient manufacturing processes.

Selecting the right LCD screen supplier is a strategic partnership. It requires looking beyond price to evaluate technical prowess, quality systems, industry experience, and communication reliability. A diligent selection process mitigates risk and lays the foundation for a successful, long-term product lifecycle.

Q1: What is the most common mistake when choosing an LCD screen supplier?

A1: The most common mistake is prioritizing the lowest unit price above all else. This often leads to compromises in quality control, material longevity, and after-sales support, resulting in higher total cost due to repairs, returns, and brand damage.

Q2: How long does it typically take to develop a custom LCD screen?

A2: The timeline varies greatly based on complexity. A minor modification (like a custom FPC connector) may take 8-12 weeks. A completely new display from the glass up can take 6 months or more. A reliable supplier will provide a detailed project timeline upfront.

Q3: Can a supplier help if I need a display that operates in very low or high temperatures?

A3: Yes, a specialized LCD screen supplier can offer industrial-grade solutions. This involves using specific liquid crystal materials, wide-temperature-range components, and sometimes incorporating heating or cooling elements into the module design.

Q4: What documents should I request from a potential LCD supplier?

A4: Essential documents include company certifications (ISO, IATF 16949 for auto), detailed product datasheets, reliability test reports, a sample evaluation process outline, and clear terms & conditions covering warranty, payment, and logistics.

Q5: How does Chuanhang Display handle logistics for international clients?

A5: Chuanhang Display manages end-to-end logistics for its international clients. They use anti-static, shock-absorbent packaging, provide full shipping documentation, and work with trusted freight forwarders to ensure door-to-door delivery with real-time tracking and customs clearance support.