Finding the right LCD display factory is a critical decision for any business integrating screens into its products. The partner you select directly impacts your product's quality, performance, and market success. This guide outlines the essential factors to consider and how a specialized manufacturer like Chuanhang Display delivers value.

An LCD display factory is more than just a supplier; it is a strategic partner. The manufacturing process involves complex technology, precise engineering, and stringent quality control. A subpar factory can lead to inconsistent quality, supply chain delays, and ultimately, product failures that damage your brand reputation.

Choosing a competent factory ensures you receive durable, high-performance displays tailored to your specific needs. It provides peace of mind regarding production timelines, technical support, and long-term reliability.

Not all factories are created equal. Here are the primary areas to evaluate.

Manufacturing Capabilities and Quality Control

A top-tier LCD display factory invests in advanced production lines and automated equipment. Look for certifications like ISO 9001, which signal a commitment to standardized quality management systems.

In-house quality control is non-negotiable. Processes should include rigorous testing at multiple stages: from raw materials (glass, polarizers, ICs) to finished modules. Tests for brightness, color gamut, viewing angle, touch functionality, and reliability under temperature/humidity stress are essential.

Chuanhang Display, for instance, operates a vertically integrated facility with strict QC protocols, ensuring every unit meets precise specifications before shipment.

Engineering Support and Customization Expertise

Standard products often don't suffice. The ability to customize LCD displays is where a true partner shines. This includes tailoring size, resolution, brightness, interface, and optical bonding.

A strong factory offers comprehensive engineering support from the design phase. They can assist with fitting the display into your device, optimizing power consumption, and ensuring electromagnetic compatibility (EMC).

When you work with a factory like Chuanhang Display, their engineering team collaborates closely to turn your concept into a viable, high-performance display module.

The global electronics supply chain can be volatile. A reputable LCD display factory has established, long-term relationships with trusted suppliers of key components like LCD panels, driver ICs, and touch sensors.

This network ensures material availability and shields your project from market shortages. It also guarantees the use of grade-A components, which is crucial for product longevity.

Your chosen partner must match your production scale, from small-batch prototypes to mass production. Clear communication about lead times for prototyping, tooling, and full-scale manufacturing is vital.

A flexible factory can ramp production up or down based on your demand without compromising quality or timelines.

Off-the-shelf displays come with limitations. Custom LCD display development solves specific design challenges and creates competitive advantages.

Tailoring to Specific Applications

Displays for medical devices demand high brightness and sterilization resistance. Automotive screens require wide temperature tolerance and high reliability. Industrial HMIs need robust touch solutions and long lifespans.

A specialized LCD display factory understands these application-specific requirements and engineers solutions accordingly.

Optical Bonding Services

Optical bonding, the process of laminating the LCD to a cover glass or touch panel, is a key customization service. It enhances readability in sunlight, improves durability, and prevents internal condensation.

Factories offering in-house optical bonding, like Chuanhang Display, provide better quality control and faster turnaround for these critical assemblies.

Integrated Touch Technologies

Choosing the right touch technology (e.g., resistive, capacitive, projective capacitive) is crucial. A full-service factory can integrate On-Cell, In-Cell, or external touchscreens, handling the complete module assembly and testing.

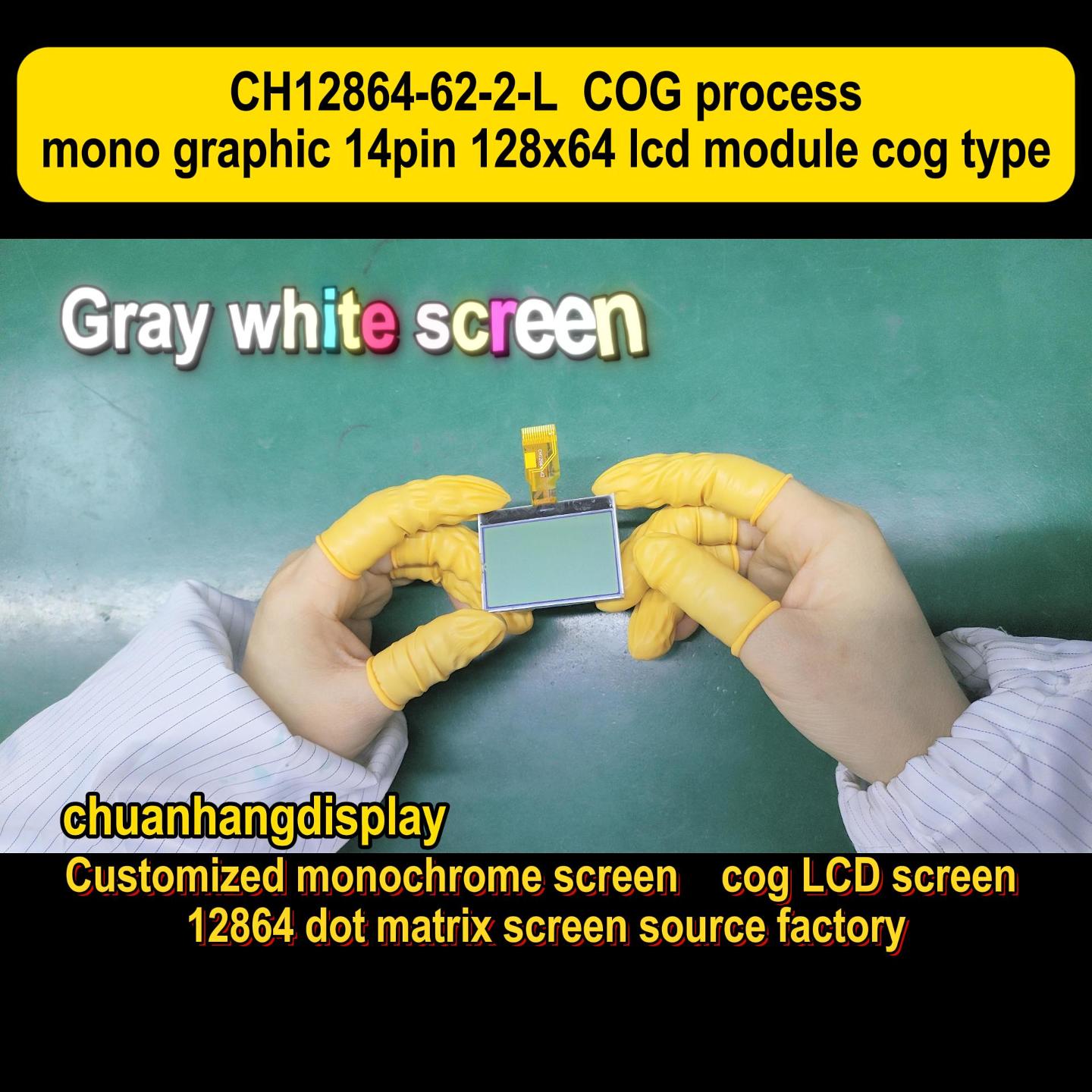

Chuanhang Display stands out as a professional LCD display factory with over a decade of experience. We focus on providing tailored display solutions for industrial, automotive, medical, and consumer applications.

Our strength lies in our end-to-end service. From initial concept and design support to prototyping, rigorous testing, and volume manufacturing, we guide clients through every step.

Our in-house engineering team excels at solving unique challenges, whether it's achieving ultra-low power consumption, extreme brightness, or complex mechanical integration. We control the entire process in our modern facility, ensuring consistent quality and competitive pricing.

For businesses seeking a reliable partner for standard or fully custom LCD displays, Chuanhang Display combines technical expertise with manufacturing excellence to bring your products to life.

Q1: What is the typical lead time for a custom LCD display project?

A1: Lead times vary. A prototype for a standard custom design can take 4-6 weeks. For entirely new designs requiring tooling, it may take 8-12 weeks. Mass production lead times depend on order volume and component availability. A reputable factory will provide a detailed timeline upfront.

Q2: What information do I need to provide to get a quote for a custom display?

A2: To get an accurate quote, provide key specifications: desired size and resolution, target brightness, preferred interface (LVDS, MIPI, etc.), touch technology requirements, operating temperature range, and estimated annual volume. Mechanical drawings are also extremely helpful.

Q3: Can you work with my provided LCD panel or touch sensor?

A3: Many factories, including Chuanhang Display, offer hybrid manufacturing services. While we typically source components for optimal quality and cost, we can often integrate specific customer-provided panels or touch sensors into a full module, subject to compatibility testing.

Q4: What is the minimum order quantity (MOQ) for custom LCD displays?

A4: MOQs depend on the customization level. For modifications to existing designs (like a custom FPC cable), MOQs can be relatively low. For fully custom displays requiring new tooling, a higher initial MOQ is standard to amortize setup costs. Discuss your needs directly with the factory.

Q5: How do you ensure display quality and reliability for harsh environments?

A5: Factories ensure reliability through careful design (selecting industrial-grade components), robust manufacturing processes like optical bonding, and comprehensive testing. This includes environmental stress testing (high/low temperature, humidity), mechanical shock/vibration tests, and extended lifespan burn-in testing to simulate real-world use.