When you think of a digital display, complex graphics might come to mind. But for many devices, clear, simple numbers and icons are all that's needed. This is where segment displays excel. However, a standard off-the-shelf model rarely fits perfectly. It might be the wrong size, shape, or lack a specific symbol. This is the exact challenge a custom segment display solves. It transforms a basic concept into a purpose-built component that aligns with your product's identity and function.

Moving beyond generic parts allows for better design integration and improved user experience. A well-executed custom segment display feels inherent to the device, not an afterthought.

A segment display is a type of electronic indicator. It forms characters or symbols using individually controlled segments. Each segment is a separate electrode.

The most common type is the seven-segment display. It can show numbers 0-9 and some letters. More complex versions exist, like 14-segment or 16-segment displays. These can show the full alphabet.

Another variant is the dot-matrix segment display. It uses a grid of dots to create more detailed shapes and icons. All these types can be customized to meet specific needs.

Standard displays work for many projects. But specific industries demand tailored solutions. A custom segment display becomes critical here.

Panel meters, timers, and process controllers need high visibility. They often operate in harsh conditions. Custom designs can include large digits, specific measurement units (like °C, psi, or RPM), and robust construction. Anti-glare treatments and wide temperature ranges are common requirements.

Dashboards, climate control units, and radio head-units use segment displays. The design must match the vehicle's aesthetic. This includes custom colors, symbol shapes for fan speed or seat heaters, and specific connector placements. Sunlight readability is a major factor.

Patient monitors, infusion pumps, and diagnostic tools require absolute clarity. Custom symbols for heartbeat, battery status, or alarm indicators are crucial. These displays often need special materials for chemical resistance and easy cleaning. High reliability is non-negotiable.

From ovens and coffee makers to thermostats and audio equipment, these displays blend function with style. A custom segment display can feature branded fonts, unique icons for cooking modes, or special decorative borders that match the appliance's design language.

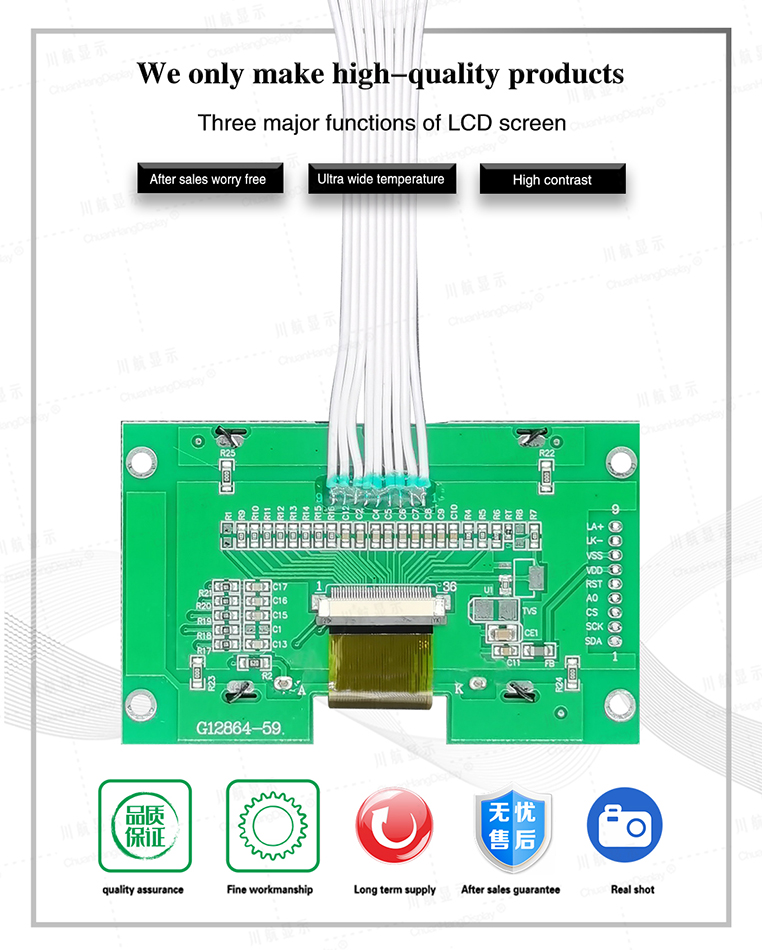

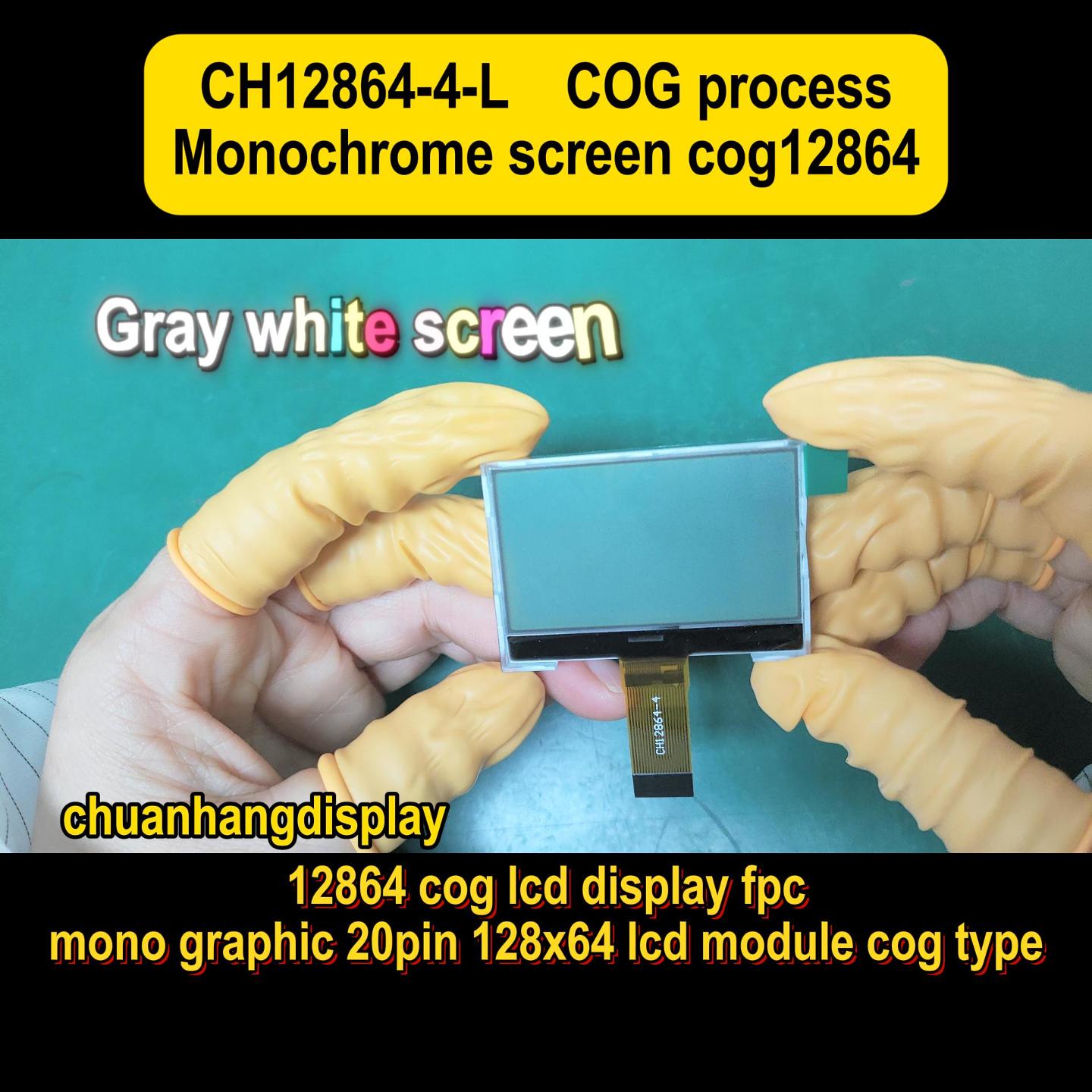

Creating a tailor-made component involves clear steps. Partnering with an experienced manufacturer like Chuanhang Display streamlines this journey.

The first step is specification. What information must be shown? This defines the number and type of segments. Physical dimensions and mounting constraints are decided. The viewing angle, operating temperature range, and required brightness are also specified.

This is the core of customization. Engineers create a precise drawing of the glass substrate. This "mask" defines the shape, size, and position of every segment, icon, and decorative element. Chuanhang Display's team assists in optimizing this layout for manufacturability and optical performance.

The display must communicate with the product's mainboard. The pinout arrangement, drive voltage, and protocol (like SPI or I2C) are defined. Customization ensures the interface matches your driver IC, simplifying integration and reducing design time.

Standard colors are black on gray or white on blue. Customization offers much more. This includes selecting specific background colors, segment colors, and polarizer types. Options like transflective polarizers for sunlight readability or integrated anti-reflective coatings can be specified.

Designing a custom component requires specific expertise. Choosing the right partner impacts cost, timeline, and final quality.

A good manufacturer provides Design for Manufacturability (DFM) feedback. They can advise on optimal segment spacing, glass thickness, and connector choices to ensure reliability and yield. Chuanhang Display's engineers help avoid common pitfalls in the design phase.

Custom glass requires a new photomask. Reputable firms manage this tooling process transparently. They then produce functional prototypes for testing and validation. This allows for design verification before committing to mass production.

Consistent quality across thousands of units is vital. Manufacturers like Chuanhang Display control their supply chain for key materials like glass, polarizers, and liquid crystal. Rigorous testing at each production stage ensures every custom segment display meets the agreed specifications.

While initial tooling has a cost, a well-optimized custom design can be cost-effective at volume. It can eliminate the need for additional overlay panels or complex assembly steps. The right partner helps balance performance with final unit economics.

Segment displays remain relevant due to their simplicity, low power consumption, and unmatched clarity for basic information. Their evolution is focused on integration and enhancement.

We see more segment displays incorporating capacitive touch elements. Others are being combined with TFT areas for hybrid interfaces. The drive is towards more functional, yet still power-efficient, human-machine interface (HMI) units.

New materials and manufacturing techniques lead to higher contrast ratios and wider viewing angles. Developments in LED backlighting allow for thinner designs and more uniform brightness across the panel.

As products strive for differentiation, the demand for tailored components grows. A custom segment display offers a direct way to achieve a unique look and optimized function that generic parts cannot provide.

In summary, a custom segment display is far more than a simple readout. It is a carefully engineered interface component. It bridges the gap between your product's internal electronics and the end-user. For designers seeking clarity, brand alignment, and functional perfection, investing in a custom solution is a logical and rewarding path.

Q1: How much does a custom segment display cost compared to a standard one?

A1: There is an initial non-recurring engineering (NRE) cost for creating the custom glass mask and tooling. However, the per-unit price in production volumes can be competitive with, or even lower than, adapting a standard display with extra filters or overlays. The total cost benefit increases with volume.

Q2: What is the typical lead time for developing a custom segment display?

A2: The timeline varies based on complexity. After finalizing specifications, prototype delivery typically takes 4-8 weeks. Mass production readiness usually requires an additional 2-4 weeks after prototype approval. Chuanhang Display can often expedite this process for urgent projects.

Q3: Can you customize the connector and pins?

A3: Yes. The electrical interface is a key part of customization. You can specify the connector type (ZIF, pin header, soldering tabs), pin count, pin pitch, and the pinout arrangement. This ensures direct compatibility with your PCB layout.

Q4: Are there limitations on the colors or symbols that can be created?

A4: The main limitation is that each distinct electrically driven area requires a separate circuit on the glass. Complex, fine-detail logos may be challenging. However, a wide palette of segment and background colors is available. Chuanhang Display's engineers can advise on the best way to realize your desired visual design.

Q5: What file format do you need for the custom symbol and layout design?

A5: Vector-based files are essential for precision. Common formats include .DXF or .DWG (from CAD software) or .AI (Adobe Illustrator). Providing clear, dimensioned drawings at the early stage helps ensure an accurate and faster design process.