If you work with compact electronic devices, you've likely encountered the challenge of integrating a display. Space is limited, reliability is paramount, and cost is always a consideration. This is where the cog module becomes a critical component. At Chuanhang Display, we specialize in the design and manufacturing of these modules, understanding their pivotal role in modern electronics.

This article breaks down everything you need to know about COG modules, from their internal structure to their ideal applications.

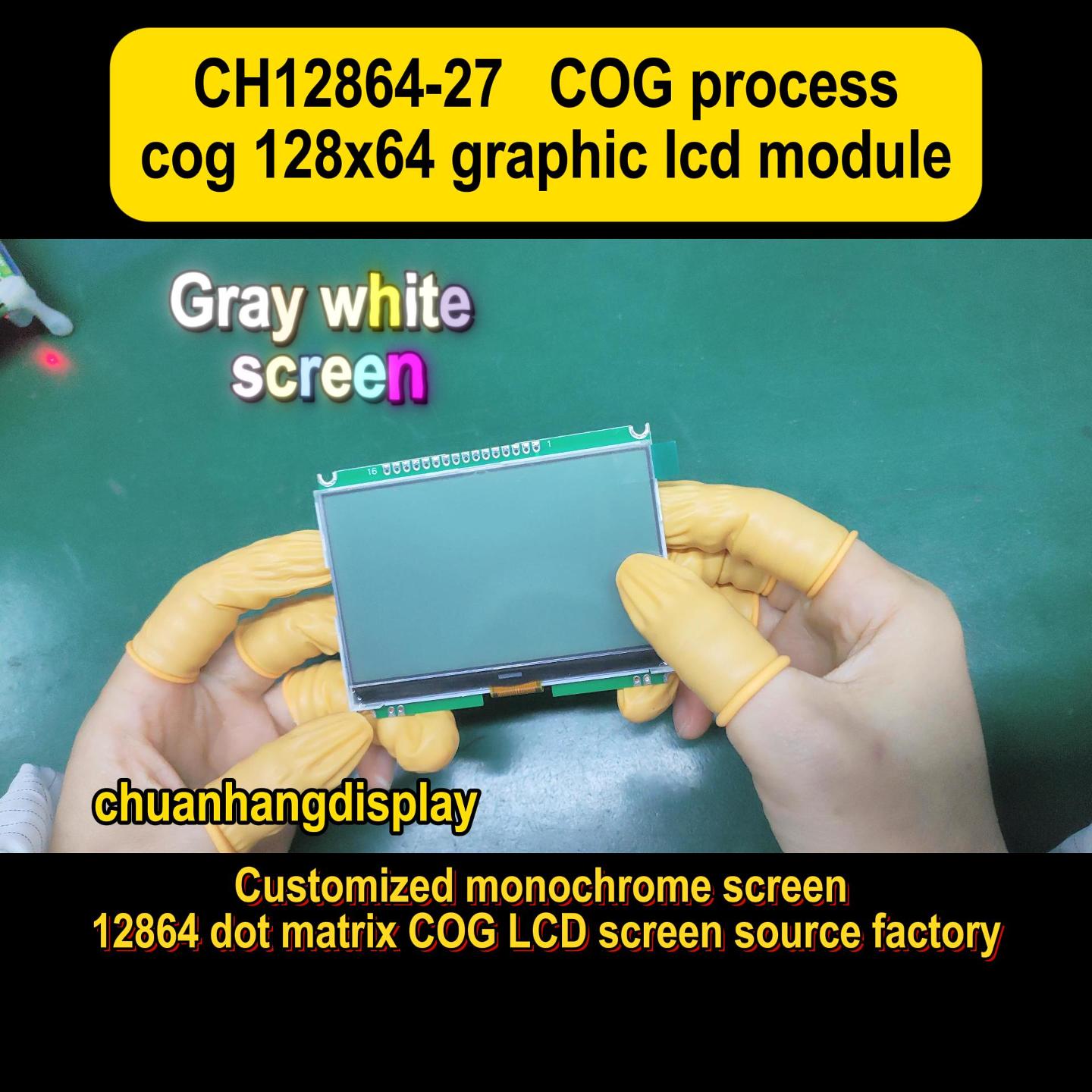

First, let's define the term. COG stands for Chip-On-Glass. A cog module is a type of LCD (Liquid Crystal Display) module where the driver Integrated Circuit (IC) is mounted directly onto the glass substrate of the LCD panel. This is a fundamental departure from older methods like COB (Chip-On-Board).

In traditional designs, the driver IC is a separate chip soldered onto a PCB, which then connects to the glass via flexible circuits. The cog module eliminates that middle step. The IC is bonded straight to the glass using a conductive adhesive. This direct attachment is the source of its major benefits.

Understanding the construction of a cog module clarifies its advantages. The core component is the glass LCD panel, which has transparent electrodes forming the pixel matrix. The driver IC, a tiny silicon chip, is precisely attached to a dedicated bonding area on the edge of this glass.

Microscopic bumps on the IC's contact pads align with corresponding pads on the glass. Through a thermal compression process, these connections are fused. This creates an electrical path from the IC directly to the display electrodes.

The cog module typically includes a few other essential parts. A flexible printed circuit (FPC) or a rigid connector is still attached to the glass to bring in power, data, and control signals from your main system processor. A backlight unit (LED light guide and reflector) is assembled behind the glass to make the image visible. Finally, a metal or plastic frame holds everything together securely.

Why would a designer choose a cog module? The benefits are significant for the right applications.

1. Space Savings and Slim Profile: This is the most compelling advantage. By removing the separate PCB for the driver IC, the overall module footprint and thickness are drastically reduced. This makes the cog module ideal for ultra-thin and compact devices like wearables, medical sensors, and slim consumer gadgets.

2. Enhanced Reliability: Fewer components and interconnections mean fewer potential points of failure. The direct glass-IC bond is robust against vibration and mechanical shock. This high reliability is why cog modules are favored in automotive dashboards, industrial controls, and medical equipment.

3. Improved Electrical Performance: The shorter electrical paths between the IC and the display pixels reduce signal noise, cross-talk, and resistance. This can result in better contrast, faster response times, and lower power consumption—a crucial factor for battery-powered devices.

4. Cost-Effectiveness in Volume: While the initial setup and tooling for a cog module can be complex, the per-unit cost in mass production becomes very competitive. The simplified assembly with fewer raw materials (no separate IC PCB) leads to long-term savings.

5. Design Flexibility: The compact nature of the cog module allows designers more freedom. It enables larger display areas within a given device size or allows for more miniaturization.

The unique strengths of the cog module make it the display solution of choice across several demanding industries.

Consumer Electronics: Smartwatches, fitness trackers, Bluetooth headsets, and portable gaming devices all benefit from the slim form factor. Any product where internal real estate is at a premium is a candidate for a cog LCD.

Automotive: From instrument clusters and radio head units to rear-seat entertainment screens, automotive displays must withstand extreme temperatures and constant vibration. The ruggedness of cog module construction meets these stringent requirements.

Medical Devices: Portable monitors, insulin pumps, and diagnostic tools require reliable, clear displays that won't fail. The high reliability and often custom-shaped designs available with cog technology are perfectly suited for this field.

Industrial and Home Appliances: Control panels for factory equipment, HVAC systems, and smart home interfaces use cog modules for their durability and long operational life in varied environmental conditions.

IoT and Wearable Technology: This is a fast-growing area. Sensors, tags, and smart clothing need tiny, low-power displays, making the cog module an essential enabler of IoT innovation.

Choosing a cog module isn't a one-size-fits-all process. Here are key factors to discuss with your supplier, like Chuanhang Display.

Display Specifications: Define your needed resolution (dots or pixels), size (diagonally), color (monochrome, grayscale, or color TFT), and viewing angle. For a cog module, also specify the desired active area.

Interface and Protocol: Determine how your main CPU will talk to the display. Common interfaces for cog modules include SPI, I2C, and MCU parallel. Ensure the module's controller is compatible.

Environmental Requirements: Outline the operating and storage temperature ranges, humidity levels, and any need for waterproofing or enhanced shock resistance.

Optical Requirements: Consider the required brightness (nits) for your use environment, contrast ratio, and whether you need a transflective display for sunlight readability.

Customization Needs: Do you need a unique shape, a special FPC tail length/angle, or an integrated touch panel? This is where partnering with an experienced manufacturer becomes vital.

While standard cog modules exist, many projects demand a tailored solution. This is where custom cog module development comes in.

At Chuanhang Display, we regularly collaborate with engineers to create custom COG LCD solutions. This process can involve:

Glass Mask Customization: Creating a new pixel pattern and layout for unique graphics or icons.

Special Shapes: Cutting the glass to non-rectangular shapes to fit innovative product designs.

Tailored Interfaces: Integrating specific controller ICs or tuning the firmware/driver to match your host processor.

Optical Bonding: Laminating a cover glass or touch sensor directly to the display to reduce glare and improve readability in bright conditions.

Enhanced Durability: Applying specific coatings or using extended temperature-range liquid crystals for harsh environments.

Investing in a custom cog module optimizes performance, aesthetics, and integration for your specific product, potentially reducing your overall system cost and complexity.

Selecting the right manufacturer is as important as selecting the right module. Chuanhang Display brings extensive experience in cog module design and mass production. We control the process from glass sourcing to final assembly, ensuring quality at every stage.

Our engineering team can guide you from the concept phase, helping you decide if a cog module is optimal or if another technology (like COF) is better. We provide full support for custom cog module projects, including rapid prototyping and rigorous testing.

We understand the balance between performance, cost, and time-to-market. For your next project requiring a compact, reliable display, consider the cog module and consider Chuanhang Display as your dedicated partner.

Q1: What is the main difference between a COG and a COF module?

A1: The key difference is where the driver IC is mounted. A COG module has the IC directly on the glass. A COF (Chip-On-Flex) module has the IC mounted on a flexible printed circuit, which is then bonded to the glass. COF can allow for even narrower borders than COG but is often a more complex and expensive process.

Q2: Are COG modules more expensive than standard LCD modules?

A2: For low-volume projects, the upfront Non-Recurring Engineering (NRE) costs for a cog module can be higher. However, for medium to high-volume production (typically thousands of units or more), the per-unit cost of a cog module often becomes lower due to material and assembly savings, making it very cost-effective.

Q3: Can a COG module have a touchscreen?

A3: Absolutely. Touch functionality, typically using resistive or capacitive technology, can be integrated into a cog module assembly. This is usually done by adding a touch sensor layer (glass or film) on top of the display, which is then connected via its own FPC tail.

Q4: What are the limitations of COG technology?

A4: The primary limitations are related to border size and flexibility. While very slim, the border where the IC is bonded cannot be made infinitesimally small. Also, the glass substrate is rigid, so a cog module itself is not flexible or bendable. For ultra-narrow borders or flexible displays, technologies like COF or OLED might be considered.

Q5: How do I request a custom COG module quote from Chuanhang Display?

A5: To get an accurate quote for a custom cog module, please provide our sales team with as much detail as possible. This includes target specifications (size, resolution, interface), a rough quantity estimate, any environmental requirements, and ideally, a sketch or drawing of your desired design. We will then work with you to develop a technical proposal and cost estimate.