In a world obsessed with 4K resolution and touchscreens, the humble segment display remains the backbone of the industrial, medical, and metering industries.

Why do engineers still specify this technology? The answer lies in three critical metrics: power consumption, reliability, and cost. When a device needs to run on a coin cell battery for five years or operate in freezing temperatures, a flashy TFT screen is a liability. A custom segment lcd display is often the only viable solution.

However, "custom" implies choices. Unlike buying an off-the-shelf module, designing a custom panel requires you to define every parameter, from the glass fluid type to the pin voltage. One wrong specification can lead to ghosting, poor contrast, or mechanical interference.

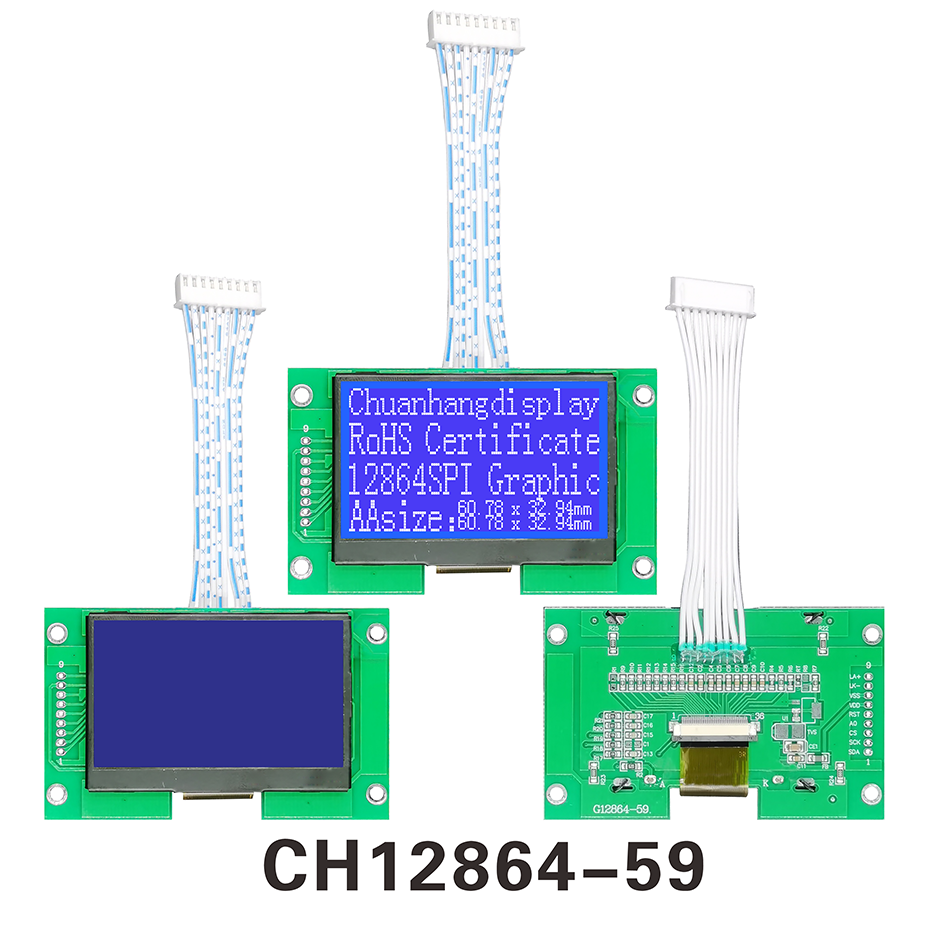

At Chuanhang Display, we guide clients through this process daily. We move concepts from a napkin sketch to a mass-produced component. This article outlines the eight critical steps you need to navigate to ensure your display performs exactly as intended.

The first technical decision involves the interface between the LCD glass and your microcontroller (MCU). This defines the layout of the internal circuit and the number of pins required.

Static Drive:In this setup, there is one pin for every single segment. If you have a digit with 7 segments, you need 8 connections (7 segments + 1 common). This provides the best possible contrast and the widest viewing angles. There is no "ghosting" because segments are either fully on or fully off. It is ideal for simple meters.

Multiplex Drive (Mux):As the complexity grows, the pin count for static drive becomes unmanageable. Multiplexing solves this. By using time-division, you drive multiple segments with fewer pins. Common duty cycles are 1/4 or 1/8.

The trade-off is contrast. The higher the multiplex rate (1/16, 1/32), the lower the contrast, because each segment is only powered for a fraction of a second. For a custom segment lcd display, we usually recommend keeping the duty cycle as low as possible (1/4 or lower) to maintain crisp visibility.

The type of fluid inside the glass sandwich dictates the viewing angle and the base color of the screen. This is a major cost driver.

TN (Twisted Nematic):This is the most cost-effective option. It works well for static drives or low duty cycles. However, the viewing cone is narrow. If you look at a TN screen from a sharp angle, the numbers might disappear or invert.

HTN (High Twisted Nematic):A slight upgrade from TN, offering a marginally wider viewing angle and better contrast.

STN (Super Twisted Nematic):STN allows for much wider viewing angles. It is the standard for industrial equipment where the user might not be standing directly in front of the device. The background color is typically a distinct yellow-green or silver-gray.

FSTN (Film Compensated STN):This adds a compensation film to the STN layer. It turns the yellow-green background into a neutral gray or white, producing a sharp black-on-white effect. For a professional, modern look, Chuanhang Display engineers frequently suggest FSTN.

VA (Vertical Alignment):If you need a "pure black" background with bright colored segments (similar to the look of an LED display but with lower power), VA is the technology to choose. It offers the highest contrast ratio of all segment technologies.

Liquid crystals have a preferred viewing direction. This is determined during the manufacturing process by the "rubbing angle" of the alignment layer.

You must specify the "clock position" of the viewer:

6:00 View: Best viewed from slightly below the normal (like a calculator on a desk).12:00 View: Best viewed from slightly above (like a dashboard in a car).

If you select a 6:00 viewing angle but mount the custom segment lcd display on a device placed high on a wall, the segments will look washed out. This is a permanent physical property of the glass and cannot be fixed with software.

Will your device sit in an air-conditioned office or a gas pump in Alaska?

Standard LCD fluids typically operate between 0°C and 50°C. Below freezing, the fluid becomes viscous, causing the numbers to change very slowly (ghosting). Above 50°C, the screen may turn completely black (isotropic phase).

For industrial applications, you must request "Wide Temperature" fluid. This extends the range typically to -20°C to +70°C. For automotive or military use, "Ultra-Wide" options can reach -30°C to +85°C.

Adding wide-temperature capabilities adds a small percentage to the unit cost, but it prevents field failures. Chuanhang Display ensures that the polarizer and adhesive layers are also rated for these temperature extremes to prevent bubbling.

How does the glass connect to your PCB? This choice impacts your assembly process and mechanical housing.

Metal Pins:Rugged and easy to solder. The pins are clipped onto the edge of the glass. This is ideal for devices subject to vibration. However, it limits how close the pixels can be to the edge of the glass.

Zebra Strip (Elastomeric Connector):A strip of conductive rubber is sandwiched between the glass and the PCB. This requires a mechanical bezel to apply constant pressure. It allows for a very low profile but makes assembly slightly more complex.

Heat Seal / FPC:A flexible cable is bonded to the glass. This allows you to locate the glass far away from the main PCB. It is useful for thin devices but is generally more expensive than pins or zebra strips.

Since segment LCDs are passive (they don't generate light), you need a solution for low-light conditions.

Reflective:No backlight. It uses a mirror on the back to reflect ambient light. This has the lowest power consumption and is perfect for outdoor meters.

Transflective:The most versatile option. The rear polarizer reflects sunlight (for daytime reading) but also allows a backlight to shine through (for nighttime reading).

Transmissive:Requires the backlight to be on constantly to be readable. This creates a very bright, high-contrast look (especially with negative mode Blue or Black backgrounds) but drains the battery faster.

When designing a custom segment lcd display, you can choose the LED color. White is standard, but amber, green, or red are often used to preserve night vision or indicate status.

Many project managers fear the word "custom" because they assume it means "expensive." In the world of segment LCDs, this is a misconception.

The NRE (Non-Recurring Engineering) tooling fee for a custom glass panel is surprisingly low—often ranging from $500 to $1,500 depending on size and complexity. This one-time fee covers the creation of the photomasks and testing jigs.

Once the tooling is paid, the unit price of a custom glass is often lower than a standard off-the-shelf module because you are not paying for features or pins you don't use.

The Chuanhang Display Workflow:

Counter Drawing: You send us your sketch or requirements. We generate a CAD drawing within 2-3 days.Approval: You review the segment layout and pinout.Tooling: We manufacture the custom masks.Samples: We ship 5-10 prototype units for your validation.Mass Production: Upon approval, we move to volume manufacturing.

Over the years, we have seen excellent circuits fail because of simple oversight in the display design.

Pinout Routing:Don't just let the software auto-route your PCB. Ensure the LCD pinout matches your MCU logic to avoid crossing tracks on your board. We can customize the pin order on the glass to simplify your PCB layout.

Segment Balance:Try to keep the surface area of different segments relatively similar. If one icon is massive and another is tiny, they may appear to have different contrast levels due to capacitive loading differences.

Ghosting Risks:Ensure your bias voltage settings in the MCU match the specification of the glass. If the bias is incorrect, "off" segments will start to darken, creating a messy appearance.

Supply chain stability is just as important as technical specs. LCD glass manufacturing is a chemical process that requires strict environmental controls.

Chuanhang Display focuses on long-term availability. We understand that if you design a custom meter today, you might still be building it in ten years. We do not end-of-life (EOL) custom parts unless absolutely necessary, and we maintain the tooling for the life of your project.

We also assist with the "invisible" specs—like optimizing the polarizer transmission rate for specific lighting environments and ensuring the Indium Tin Oxide (ITO) glass resistance is low enough for your duty cycle.

Q1: What is the typical lead time for a custom segment lcd display?

A1: The timeline is generally faster than people expect. Once you approve the technical drawing (counter drawing), tooling and sample production usually take 12 to 15 working days. Mass production lead times typically range from 4 to 6 weeks, depending on the current factory load and material availability.

Q2: Can I integrate a touch screen with a segment LCD?

A2: Yes, it is possible. We can bond a Resistive or Capacitive touch panel over the segment glass. However, because segment displays are often used in rugged or cost-sensitive applications, designers often prefer simple membrane switches or physical buttons. If you need a touch interface, ensure the LCD glass is rigid enough to handle the pressure.

Q3: What is the difference between Positive and Negative mode?

A3: Positive mode features dark characters on a light background (like a standard digital watch). It is readable without a backlight in well-lit rooms. Negative mode features light characters on a dark background. Negative mode must have a backlight to be readable. Negative mode often looks sleeker and more high-tech, but it consumes more power due to the backlight requirement.

Q4: My display shows "shadows" or ghosting. How do I fix this?

A4: Ghosting is usually caused by an incorrect operating voltage (VLCD) or an improper Bias setting. If the voltage supplied to the glass is too high, the segments that should be "off" will partially turn on. You need to lower the VLCD or adjust the contrast setting in your firmware. If the issue persists, the viewing angle specification of the glass might not match the user's position.

Q5: Is there a minimum order quantity (MOQ) for custom designs?

A5: At Chuanhang Display, we try to be flexible to support new product development. While standard mass production runs might require 1,000 to 5,000 units to be most cost-effective, we can support smaller pilot runs. The tooling fee must be paid upfront, but after that, we can discuss batch sizes that fit your inventory planning.

A custom segment lcd display is not outdated technology; it is efficient technology. It delivers exactly the information the user needs without the power drain or complexity of a dot-matrix screen.

By controlling the design variables—from fluid type to pin layout—you create a component that fits your mechanical housing perfectly and operates reliably in your specific environment.

Don't settle for a standard module that forces you to compromise your product design. Contact Chuanhang Display today to discuss your project requirements. Let us help you engineer a display solution that balances performance, longevity, and cost.