In today’s fast-paced technological landscape, LCD displays are ubiquitous—from smartphones and televisions to medical devices and automotive dashboards. As demand grows, selecting the right LCD factory becomes critical for businesses aiming to integrate high-quality displays into their products. An LCD factory isn’t just a manufacturing facility; it’s a hub of innovation, precision, and customization that can make or break your project’s success. In this article, we’ll delve into the essential aspects of partnering with an LCD factory, focusing on solutions, applications, and how a manufacturer like Chuanhang Display excels in this competitive field. Whether you’re sourcing standard panels or need tailored solutions, understanding these factors will help you navigate the complexities of LCD production and ensure a seamless collaboration.

An LCD factory is specialized in producing liquid crystal display (LCD) panels through a multi-step process that includes designing, assembling, and testing displays. These facilities combine advanced machinery with skilled labor to create everything from basic screens to intricate, custom LCD displays. The global LCD market has evolved significantly, with factories now emphasizing efficiency, sustainability, and adaptability. For instance, a reliable LCD factory doesn’t just mass-produce units; it offers scalable solutions that cater to diverse industry needs. This is where companies like Chuanhang Display stand out, leveraging years of expertise to deliver displays that meet international standards. By partnering with a reputable LCD factory, businesses can reduce costs, accelerate time-to-market, and enhance product reliability. In essence, the right LCD factory acts as a strategic partner, driving innovation while maintaining quality control.

When evaluating an LCD factory, it’s crucial to assess the range of solutions it provides. A top-tier facility, such as Chuanhang Display, typically offers end-to-end services that cover design, prototyping, mass production, and post-sales support. One key solution is customization—many clients require bespoke displays tailored to specific dimensions, resolutions, or environmental conditions. For example, a custom LCD display might involve unique touchscreen capabilities or enhanced durability for outdoor use. Another solution is integrated supply chain management, where the LCD factory handles sourcing components like backlights and drivers, ensuring consistency and reducing lead times. Additionally, factories often provide technical consulting to help clients optimize their designs for cost-efficiency and performance. By offering these comprehensive solutions, an LCD factory like Chuanhang Display enables businesses to focus on their core operations while trusting that their display needs are in expert hands.

The versatility of LCD technology means that an LCD factory serves a wide array of sectors. In the consumer electronics industry, LCDs are the backbone of devices like laptops, tablets, and smart home appliances, where clarity and energy efficiency are paramount. The automotive sector relies on LCD factories for dashboard displays and infotainment systems, requiring robust panels that withstand vibrations and temperature fluctuations. Medical equipment, such as patient monitors and diagnostic tools, demands high-resolution, reliable displays produced in a sterile LCD factory environment to ensure accuracy and safety. Industrial applications include control panels and machinery interfaces, where custom LCD displays with sunlight readability or wide viewing angles are essential. Even the retail and advertising industries benefit from digital signage solutions crafted by specialized LCD factories. Chuanhang Display, for instance, has experience across these domains, providing tailored displays that meet stringent regulatory and performance standards. This broad applicability underscores why choosing a versatile LCD factory is vital for innovation and market adaptability.

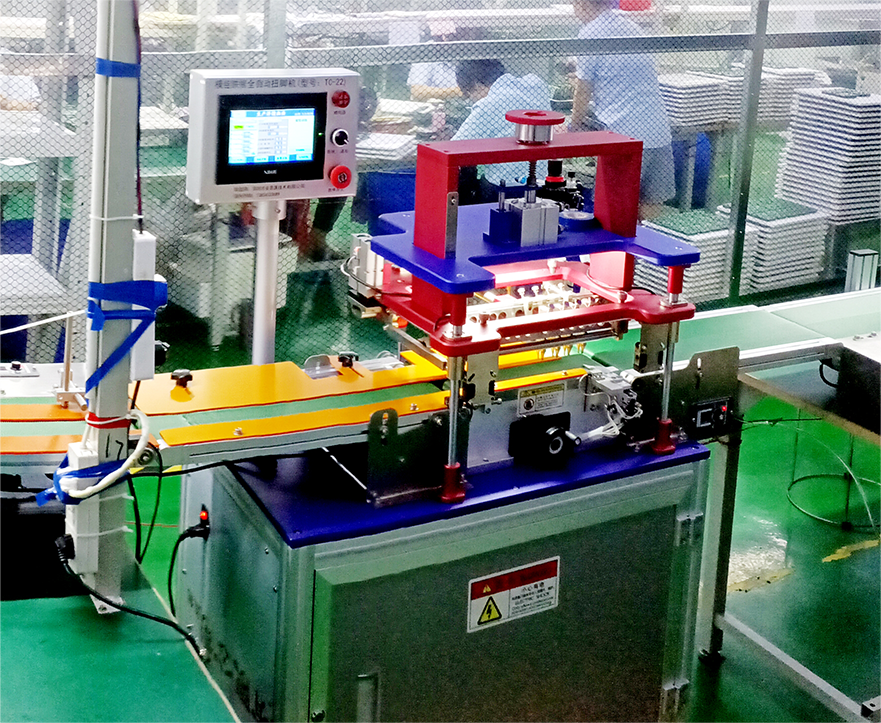

Chuanhang Display has built a reputation as a leading LCD factory by prioritizing quality, innovation, and customer-centric approaches. With state-of-the-art manufacturing facilities, they employ automated production lines and rigorous testing protocols to ensure every display meets international benchmarks. One of their strengths lies in customization—they work closely with clients to develop custom LCD displays that align with unique specifications, whether it’s for niche industrial use or high-volume consumer products. Their team of engineers provides expert guidance on material selection and design optimization, reducing development cycles and costs. Moreover, Chuanhang Display emphasizes sustainability, using eco-friendly materials and energy-efficient processes in their LCD factory operations. This commitment not only aligns with global trends but also appeals to environmentally conscious businesses. By fostering long-term partnerships, Chuanhang Display demonstrates how a dedicated LCD factory can drive success through reliability and adaptability in a dynamic market.

Customization is a cornerstone of modern LCD factory services, allowing businesses to differentiate their products in a crowded marketplace. When you partner with an LCD factory like Chuanhang Display, you gain access to a spectrum of customization options. These can include tailoring screen sizes, resolutions, and aspect ratios to fit specific device housings. For instance, a custom LCD display might feature integrated touch technology, such as capacitive or resistive touchscreens, for interactive applications. Other bespoke elements involve environmental enhancements—like wide-temperature operation for automotive or military uses—or optical bonding to reduce glare in bright conditions. The process typically begins with a consultation where the LCD factory assesses your requirements, followed by prototyping and iterative testing. This hands-on approach ensures that the final product not only meets technical specs but also aligns with user experience goals. By leveraging these services, companies can innovate faster and respond to market demands with agility.

Quality control is non-negotiable in an LCD factory, as even minor defects can lead to product failures or safety issues. Reputable factories, including Chuanhang Display, implement multi-stage inspection processes throughout production. This starts with incoming material checks, where components like glass substrates and liquid crystals are verified for purity and performance. During assembly, automated optical inspection (AOI) systems scan for imperfections in the LCD panels, such as dead pixels or misalignments. Environmental testing follows, simulating conditions like humidity, shock, and temperature extremes to ensure durability. For custom LCD displays, additional validation might include lifespan testing under continuous operation. By adhering to standards such as ISO 9001, an LCD factory guarantees consistency and reliability. This rigorous approach minimizes recalls and enhances customer trust, making it a key factor in selecting a manufacturing partner.

The LCD industry is continuously evolving, and forward-thinking factories are adapting to trends like mini-LED backlighting, flexible displays, and IoT integration. For an LCD factory, this means investing in R&D to stay ahead of technological curves. Mini-LEDs, for example, offer improved contrast and energy efficiency, making them ideal for high-end televisions and professional monitors. Flexible LCDs are gaining traction in wearable devices and curved screens, requiring factories to upgrade their production techniques. Additionally, the rise of smart devices demands displays with embedded sensors and connectivity, which an LCD factory can provide through collaborative innovation. Chuanhang Display is already exploring these avenues, positioning itself as a future-ready partner. By anticipating market shifts, an LCD factory not only sustains growth but also empowers clients to launch cutting-edge products.

Selecting the right LCD factory is a strategic decision that impacts product quality, cost, and time-to-market. By considering factors like customization capabilities, industry experience, and quality assurance, businesses can forge partnerships that drive long-term success. Chuanhang Display exemplifies how a dedicated LCD factory combines expertise with flexibility to meet diverse needs. As technology advances, the role of these factories will only become more integral to innovation across sectors. Whether you’re launching a new device or upgrading an existing one, investing time in choosing a reliable LCD factory will yield dividends in performance and customer satisfaction.

Q1: What is the typical lead time for a custom LCD display order from an LCD factory?

A1: The lead time varies based on complexity and order volume, but generally, it ranges from 4 to 8 weeks for standard customizations. For more intricate designs, an LCD factory like Chuanhang Display might require additional time for prototyping and testing to ensure quality.

Q2: How does an LCD factory ensure the quality of its products?

A2: An LCD factory employs rigorous quality control measures, including automated optical inspections, environmental stress tests, and performance checks. For instance, Chuanhang Display follows international standards, conducting multiple audits throughout production to detect defects early and maintain high reliability.

Q3: Can I request samples before placing a bulk order with an LCD factory?

A3: Yes, most reputable LCD factories, including Chuanhang Display, offer sample units for evaluation. This allows clients to verify the design, functionality, and quality of custom LCD displays before committing to large-scale production.

Q4: What are the minimum order quantities (MOQs) for a custom LCD factory?

A4: MOQs depend on the factory and the customization level. At Chuanhang Display, they often accommodate flexible MOQs, starting from as low as 100 units for standard projects, though highly specialized custom LCD displays might require higher minimums to offset setup costs.

Q5: How does an LCD factory handle sustainability and environmental concerns?

A5: Modern LCD factories prioritize sustainability by using lead-free materials, reducing energy consumption, and implementing recycling programs. Chuanhang Display, for example, adheres to RoHS and REACH regulations, ensuring eco-friendly practices in their manufacturing processes to minimize environmental impact.