If you're designing a product that needs to show more than just numbers, you've likely come across the term "graphic LCD display module." Unlike simple character displays, these modules let you control individual pixels. This opens up possibilities for custom icons, complex data visualizations, and even basic animations.

Choosing the right graphic LCD display module is critical. The wrong choice can lead to development headaches, cost overruns, or a poor user experience. This post cuts through the noise. We'll break down what you need to know, from core technology to finding a reliable partner like Chuanhang Display.

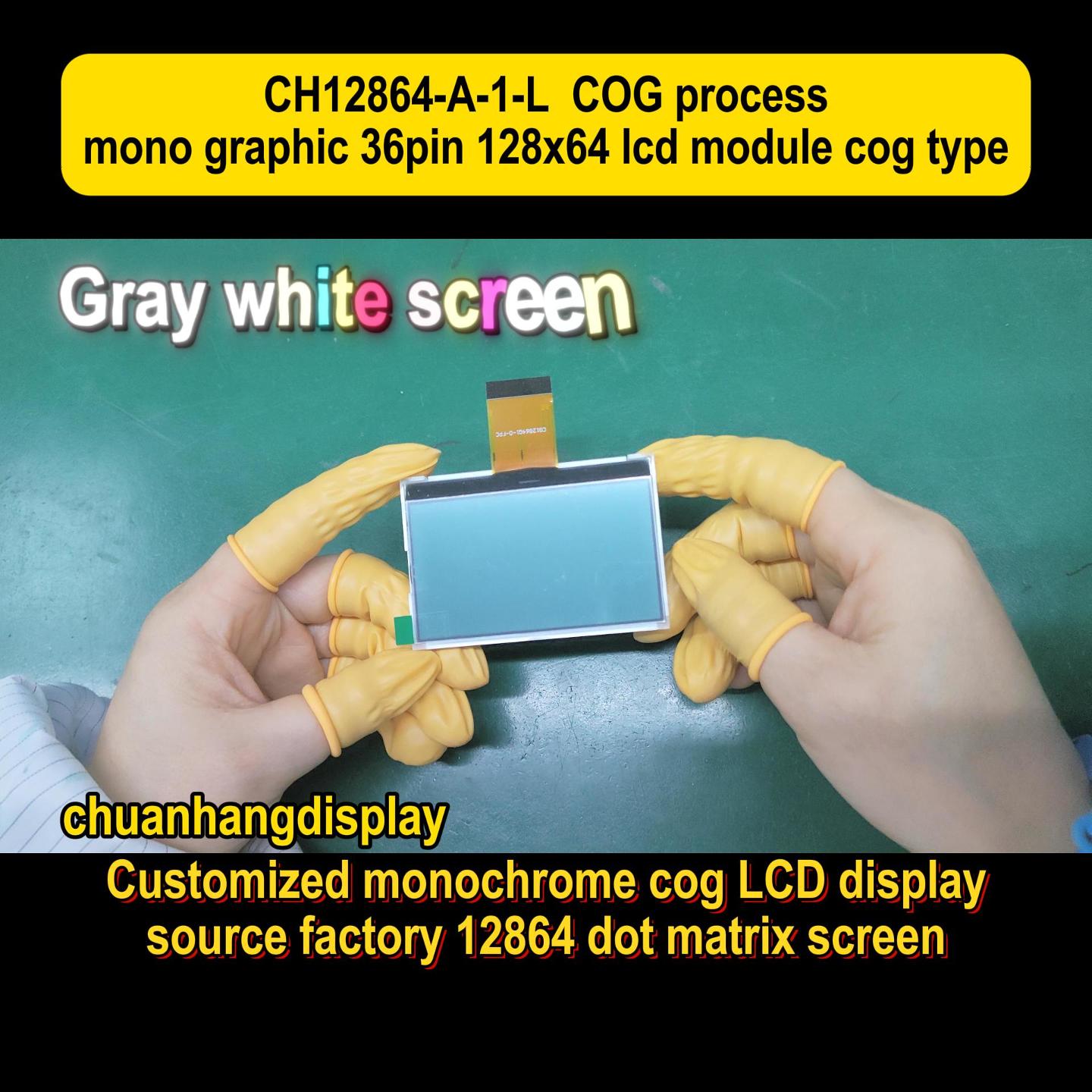

At its heart, a graphic LCD display module is a type of liquid crystal display designed to render arbitrary images. It consists of a matrix of pixels—dots you can turn on or off. Common resolutions include 128x64, 240x128, or 320x240. The "module" part means it includes the LCD glass, driver circuitry, and usually a controller chip.

This controller is key. It handles the complex task of mapping pixel data from your microcontroller to the correct spots on the screen. Modules with built-in controllers, like those with ST7920 or RA8835 chips, drastically simplify your firmware development.

Understanding this basic architecture is the first step. It explains why a graphic LCD module is more versatile than a segment or character display for dynamic interfaces.

How does a graphic LCD stack up against other common display types? Let's compare.

Graphic LCD vs. Character LCD: Character LCDs (like 16x2 lines) are limited to a fixed set of alphanumeric characters. A graphic LCD display module gives you a blank canvas. Need a custom battery icon or a unique font? Only a graphic module can do that.

Graphic LCD vs. TFT: Color TFTs are also pixel-based but use different technology. TFTs offer full color and faster refresh rates. However, a monochrome graphic LCD module consumes far less power, is more readable in direct sunlight, and is often more cost-effective for simple, non-color applications.

Graphic LCD vs. OLED: OLEDs provide superior contrast and viewing angles. Yet, a standard graphic LCD module typically has a longer lifespan, especially for static content, and is less susceptible to screen burn-in. It remains a workhorse for industrial and medical equipment.

The strength of the graphic LCD display module lies in its balanced performance: good readability, low power, and pixel-level control without the cost of a full-color TFT.

Where do you find these modules in the wild? Their application is vast.

In industrial automation, a graphic LCD module is the face of many control panels. It shows machine status, sensor readings in graph form, and diagnostic menus. Their reliability in harsh environments is a major plus.

Medical devices frequently use them. Patient monitors, infusion pumps, and portable diagnostic tools rely on the clarity and stability of a graphic LCD display. They provide critical information without distraction.

Consumer electronics like coffee makers, audio equipment, and smart home controllers use them for intuitive user interfaces. A custom graphic LCD can be designed to fit the exact brand aesthetic.

Test and measurement equipment, from oscilloscopes to multimeters, uses these modules to plot waveforms and display complex data sets. The ability to update specific screen sections is highly valuable here.

Selecting a graphic LCD display module isn't just about picking a size. Follow this practical checklist.

1. Resolution and Size: Determine the physical dimensions and pixel count you need. A 128x64 graphic LCD module is a standard starting point for many interfaces. Need more detail? A 240x128 or higher might be necessary.

2. Display Technology: STN (Super Twisted Nematic) is common and cost-effective. FSTN (Film-compensated STN) offers better contrast and viewing angle. Consider the viewing environment.

3. Interface: Parallel interfaces (8-bit or 4-bit) are fast. SPI or I2C serial interfaces save microcontroller pins. Choose based on your processor's capabilities and pin availability.

4. Backlight: LED backlight color (white, blue, green, amber) and brightness matter. Decide if you need constant current drive or PWM dimming control.

5. Temperature Range: Commercial (0°C to 50°C) or industrial/wide temperature (-20°C to +70°C)? This is a critical spec for any product not used in a climate-controlled office.

6. Customization: Do you need a special shape, connector placement, or optical bonding? This is where working with a manufacturer like Chuanhang Display pays off. They can provide a custom graphic LCD display module tailored to your mechanical and electrical design, saving you integration time.

The price of a graphic LCD display module isn't fixed. Several factors drive cost.

Volume: This is the biggest factor. Unit price drops significantly with higher order quantities. Prototyping with small batches will have a higher per-unit cost.

Resolution and Size: More pixels and a larger glass area increase cost. A 320x240 module will cost more than a 128x64 unit.

Technology and Features: FSTN panels cost more than STN. Wide-temperature models are more expensive. Integrated touch panels (resistive) will add cost.

Customization: A standard, off-the-shelf graphic LCD module is the most affordable. Any modification—be it a custom FPC (Flexible Printed Circuit) length, special polarizer, or unique outline—adds to the Non-Recurring Engineering (NRE) and unit cost.

Supplier Choice: Partnering with an integrated manufacturer like Chuanhang Display often provides better long-term value than using a distributor. They control the production line, from glass to finished module, ensuring quality and often more competitive pricing for volume projects.

Sourcing a graphic LCD display module involves more than finding the lowest price. You need a partner for the long run.

Look for a supplier with proven engineering support. Can they help debug initialization code or suggest optimizations? Chuanhang Display provides technical documentation and direct engineer-to-engineer communication, which is invaluable during development.

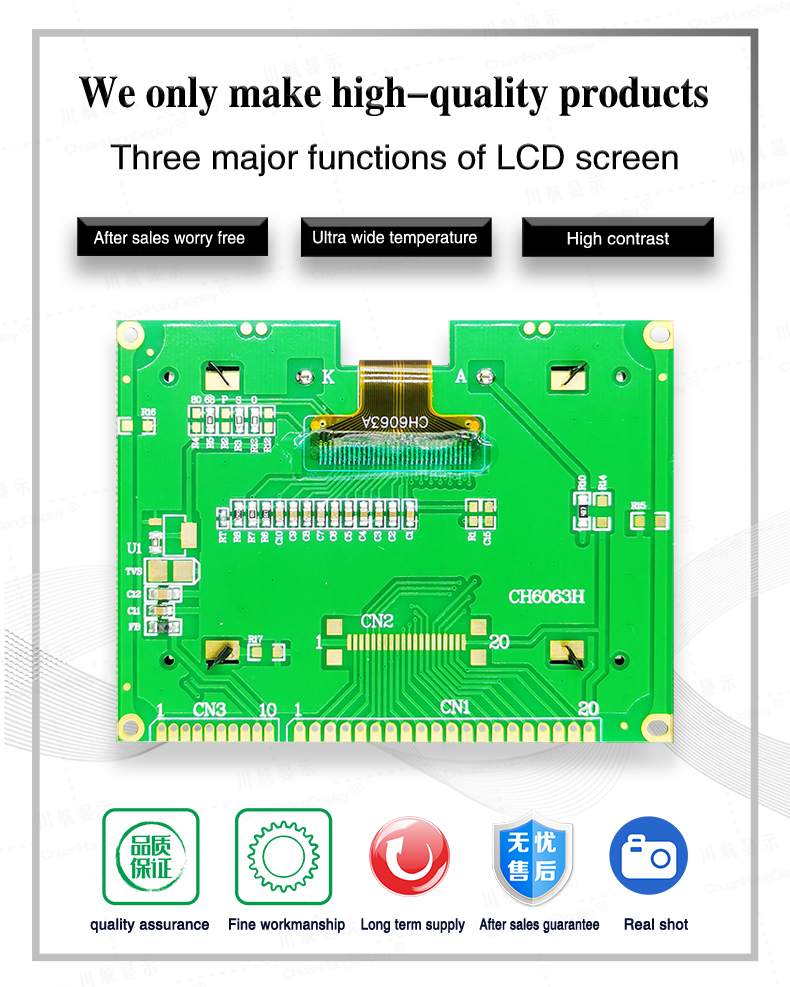

Manufacturing capability is key. Do they own the entire process, from cell assembly to module bonding? Vertical integration, as practiced by Chuanhang Display, leads to better quality control and faster turnaround on custom graphic LCD display module requests.

Check their commitment to consistency. Display modules must be identical from batch to batch. A reliable supplier will have strict quality control protocols, including electrical testing and visual inspection of every unit.

Finally, evaluate their willingness to support smaller prototype orders before you commit to mass production. A good partner, like Chuanhang Display, understands this need and facilitates a smooth transition from design to volume manufacturing.

The graphic LCD display module remains a fundamental component for countless electronic products. Its blend of pixel-level control, reliability, and cost-effectiveness ensures its relevance.

Successful integration depends on a clear understanding of your technical requirements and a strong partnership with your supplier. By focusing on the specs that matter for your application and collaborating with an expert manufacturer like Chuanhang Display, you can leverage the full potential of this versatile technology.

Q1: What is the main advantage of a graphic LCD over a character LCD?

A1: The main advantage is pixel-level control. A graphic LCD display module allows you to draw any image, icon, or custom font, while a character LCD is limited to a fixed set of pre-defined characters and symbols.

Q2: Can graphic LCD modules display images or logos?

A2: Absolutely. That's one of their primary functions. You can convert a black-and-white image or logo into a pixel map (bitmap) and send that data to the controller of the graphic LCD module to render it on the screen.

Q3: What does "STN" and "FSTN" mean for these displays?

A3: STN (Super Twisted Nematic) and FSTN (Film-compensated STN) refer to the LCD cell technology. STN is standard and can have a slight color background (often blue or green). FSTN uses a compensation film to produce a truly black-on-white (or white-on-black) high-contrast display with a wider viewing angle.

Q4: How do I communicate with a graphic LCD module from my microcontroller?

A4: Communication is typically via a parallel or serial interface (like SPI or I2C). You send commands and pixel data to the module's built-in controller chip according to its specific timing diagram and instruction set. The datasheet from your supplier, such as Chuanhang Display, provides all necessary details.

Q5: Is it possible to get a graphic LCD module in a non-rectangular shape?

A5: Yes, but it involves custom tooling. The glass inside a standard graphic LCD display module is rectangular. However, the front polarizer and mask can be custom-cut to create round, oval, or other shaped viewing areas. This is a custom graphic LCD display module service offered by specialized manufacturers.